Novel cement paste for well cementation

A technology for oil well cement slurry and cement slurry, which is applied in the field of oil well cement slurry, can solve the problems of performance restriction, many types of cement slurry composition, difficulty in debugging the performance of cement slurry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

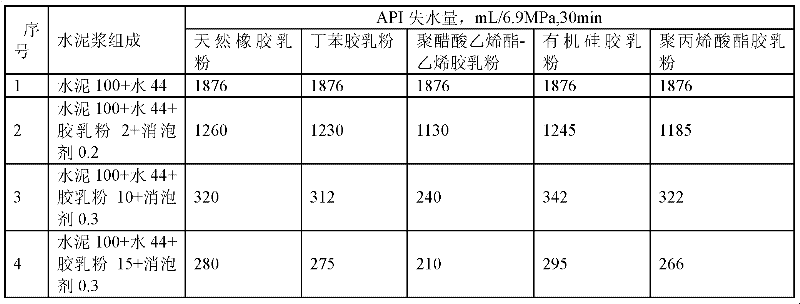

[0016] Example 1: Water loss reduction performance test of cement slurry used for well cementing in this application

[0017] High sulfur-resistant G-grade oil well cement is used to prepare cement slurry according to the pulping method of oil well cement. The basic composition of the slurry is: oil well cement, tap water, latex powder (respectively natural rubber milk powder, styrene-butadiene latex powder, polyvinyl acetate) -vinyl latex powder, organic silica gel latex powder and polyacrylate latex powder), defoamer; in this experiment, the latex powder mentioned above is dry mixed in cement, then mixed with tap water to make cement slurry according to the API method, The latex powder mentioned above can also be uniformly dispersed in tap water, and then mixed with cement to make cement slurry according to the API method. These two mixing methods have no effect on the performance of cement slurry. The prepared cement slurry was placed in an atmospheric thickener and stirred...

Embodiment 2

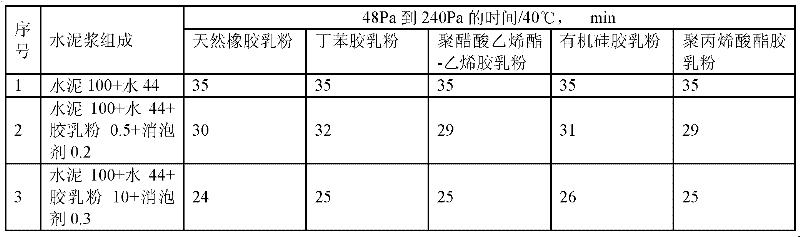

[0020] Embodiment 2: the anti-channeling performance test of the cement slurry of the present application

[0021] The anti-channeling performance of oil well cement slurry can use ultrasonic static gel strength tester to evaluate the development time of cement slurry structural strength from 48Pa to 240Pa. The shorter the time, the stronger the anti-channeling performance of cement slurry. The cement slurry prepared in Example 1 was used to evaluate the anti-channeling property according to the API standard method. The test results are shown in Table 2.

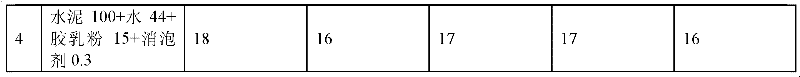

[0022] The static gel strength development of the cement slurry prepared by the above-mentioned latex powder of different dosages in table 2

[0023]

[0024]

Embodiment 3

[0025] Embodiment 3: the elastic modulus test of cement stone

[0026] Mix different amounts of the above-mentioned latex powder into the oil well cement stone, cure the cement slurry according to the API specification method, and then demould, and test the elastic modulus of the cement stone. The test results are shown in Table 3.

[0027] The elastic modulus of the cement slurry prepared by the latex powder of different content in table 3

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com