Heat shrink tube for automobile, and preparation method thereof

A heat-shrinkable tube and automobile technology, which is applied in the field of automobile wiring harness production, can solve the problems of poor flame retardancy and irritating odor, and achieve the effect of improving the flame retardancy level and eliminating the irritating odor

Inactive Publication Date: 2017-06-27

SHANGHAI HUALIU ELECTRONICS TECH CO LTD

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the existing heat-shrinkable tube raw materials have problems such as poor flame retardancy and pungent odor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

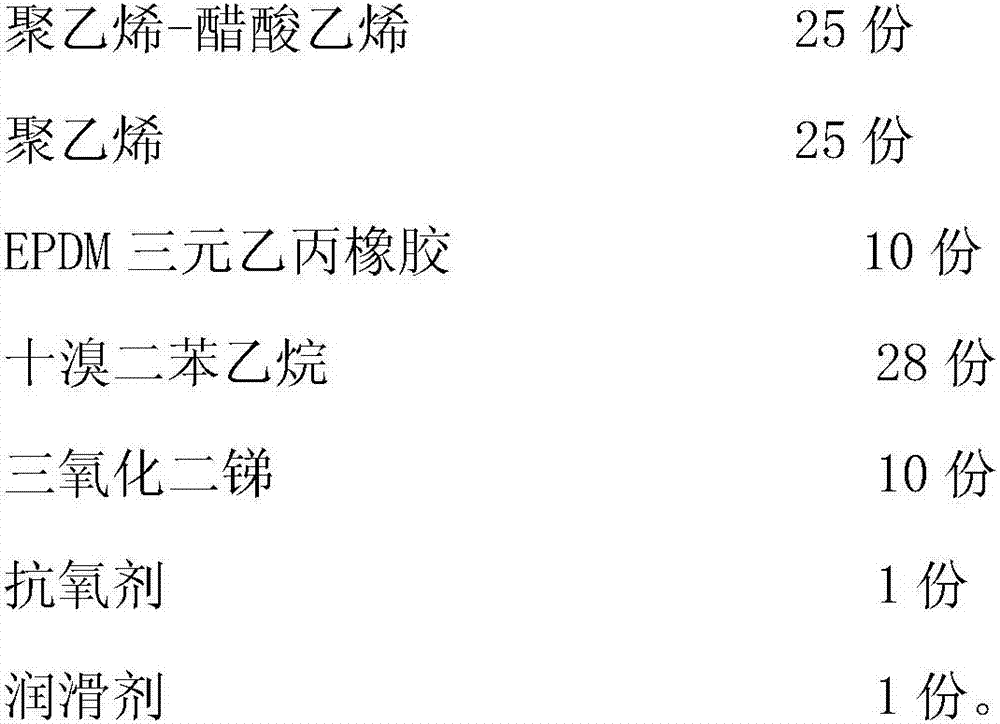

Embodiment 1

[0011]

Embodiment 2

[0013]

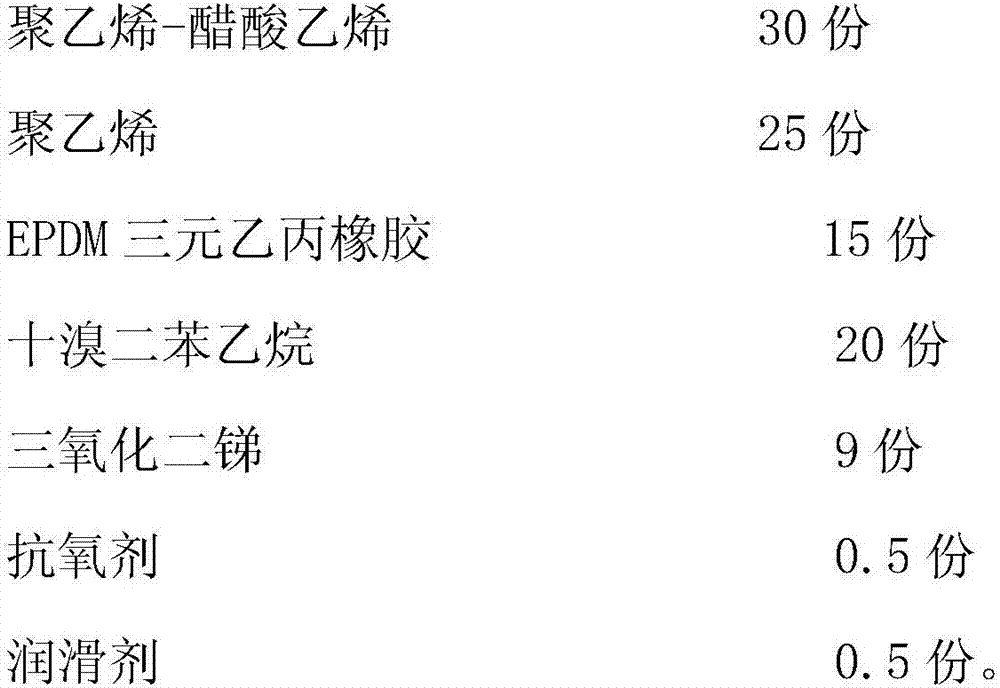

Embodiment 3

[0015]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

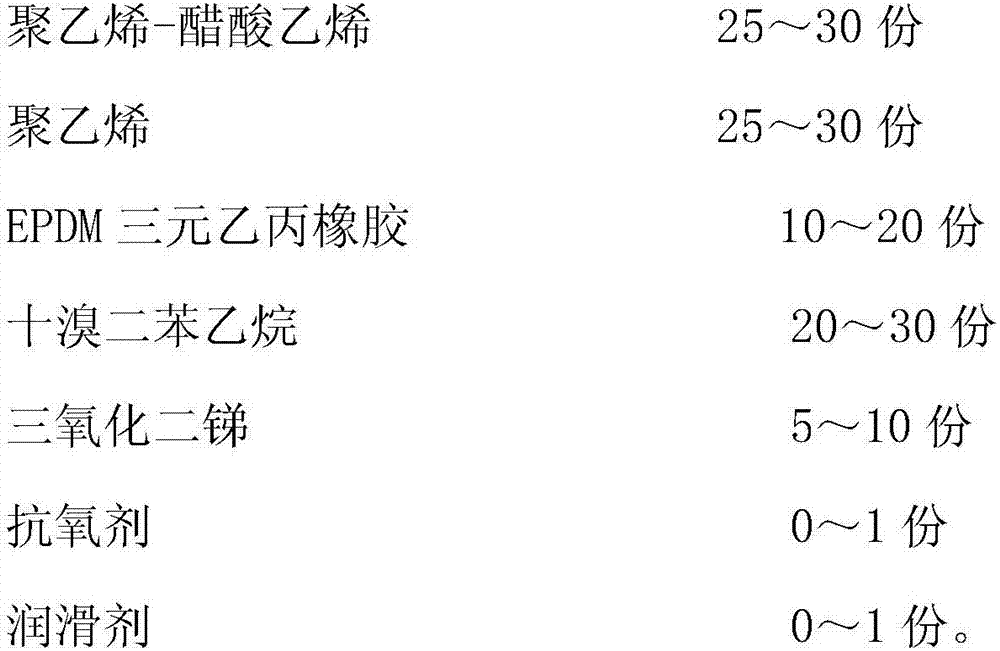

The invention discloses a heat shrink tube for an automobile, and a preparation method thereof. The heat shrink tube for the automobile is characterized by comprising the following raw materials in parts by weight: 25 to 30 parts of polyethylene-vinyl acetate, 25 to 30 parts of polyethylene, 10 to 20 parts of ethylene-propylene-diene monomer (EPDM), 20 to 30 parts of decabromodiphenyl ethane, 5 to 10 parts of antimonous oxide, 0 to 1 part of an antioxidant, and 0 to 1 part of a lubricating agent. The heat shrink tube for the automobile has the following beneficial effects: the new raw materials are added in the formula and the original proportion is adjusted, so that under the condition of not changing the original physical performance, the flame-retardant level is greatly increased, and the pungent smell is eliminated.

Description

technical field [0001] The invention relates to the technical field of automobile wire harness production, in particular to a heat-shrinkable tube for automobiles and a preparation method thereof. Background technique [0002] At present, the main materials used to produce heat-shrinkable tubing include: ① olefin polymers or copolymers; ② rubber-like materials or thermoplastic elastomers styrene-butadiene-styrene block copolymer (SBS), styrene - One or more materials in the isoprene block copolymer (SIS); ③ other auxiliary materials. However, the existing heat-shrinkable tube raw materials have problems such as poor flame retardancy and pungent odor. Contents of the invention [0003] The object of the present invention is to provide a heat-shrinkable tube for automobiles and a preparation method thereof, which can greatly improve the flame retardancy level and eliminate the pungent smell. [0004] To achieve the above object, the present invention provides the following...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L23/06C08L23/16C08K3/22C08K5/03

CPCC08L23/0853C08L23/06C08L2201/02C08L2203/18C08L2205/02C08L2205/03C08L23/16C08K3/2279C08K5/03

Inventor 孙国军

Owner SHANGHAI HUALIU ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com