B2 grade flame retardation polyurethane foam material

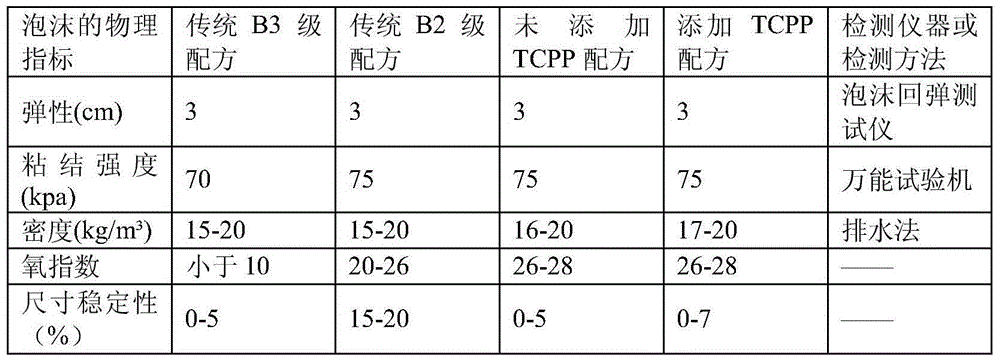

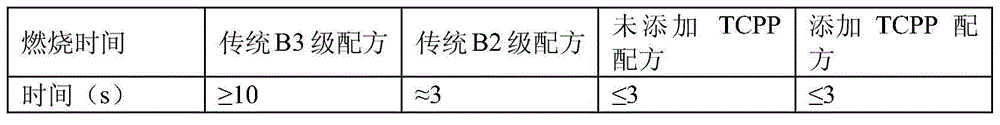

A foaming material and polyurethane technology, applied in the field of foam gap filler, can solve the problems of unstable flame retardant effect and poor dimensional stability, and achieve the effect of ensuring dimensional stability, low production cost and taking into account the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh each component according to the following parts by mass: 20 parts of polyether polyol I, 45 parts of polyether polyol II, 20 parts of mixed flame-retardant polyether polyol III, 55 parts of paraffin, polyether modified polysiloxane 3 parts, 4 parts of 2,2-dimorpholino diethyl ether, 350 parts of isocyanate, 70 parts of methyl ether, 30 parts of liquefied petroleum gas;

[0029] Polyether polyol I has a molecular weight of 1000 and a functionality of 3, polyether polyol II has a molecular weight of 400 and a functionality of 2, and the mixed flame-retardant polyether polyol III has an average molecular weight of 1000 and an average functionality of 2.6.

[0030] The model of polyether modified polysiloxane is GN-GY-505, the model of polyether polyol I is polyether polyol 310, the model of polyether polyol II is polyether polyol 204, and the mixed flame retardant polyol The model of ether polyol III is polyether polyol GN-JM-6110.

[0031] The ratio of propane ...

Embodiment 2

[0037] (1) Weigh each component according to the following mass parts: 40 parts of polyether polyol I, 35 parts of polyether polyol II, 30 parts of mixed flame-retardant polyether polyol III, 65 parts of paraffin, polyether modified polysiloxane 4 parts, 3 parts of 2,2-dimorpholino diethyl ether, 300 parts of isocyanate, 60 parts of methyl ether, 60 parts of liquefied petroleum gas;

[0038] Polyether polyol I has a molecular weight of 1000 and a functionality of 3, polyether polyol II has a molecular weight of 400 and a functionality of 2, and the mixed flame-retardant polyether polyol III has an average molecular weight of 1000 and an average functionality of 2.6;

[0039] The model of polyether modified polysiloxane is GN-GY-505, the model of polyether polyol I is polyether polyol 310, the model of polyether polyol II is polyether polyol 204, mixed flame retardant polyether The model of polyol III is polyether polyol GN-JM-6100;

Embodiment 3

[0044] (1) Weigh each component according to the following mass parts: 60 parts of polyether polyol I, 20 parts of polyether polyol II, 25 parts of mixed flame-retardant polyether polyol III, 60 parts of paraffin, polyether modified polysiloxane 5 parts, 2 parts of 2,2-dimorpholino diethyl ether, 330 parts of isocyanate, 50 parts of methyl ether, 40 parts of liquefied petroleum gas;

[0045] Polyether polyol I has a molecular weight of 1000 and a functionality of 3; polyether polyol II has a molecular weight of 400 and a functionality of 2; the mixed flame-retardant polyether polyol III has an average molecular weight of 1000 and an average functionality of 2.6.

[0046] The model of polyether modified polysiloxane is GN-GY-505, the model of polyether polyol I is polyether polyol 310, the model of polyether polyol II is polyether polyol 204, mixed flame retardant polyether The model of polyol III is polyether polyol GN-JM-6100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com