Preparation method of flame-retardant polyurethane resin

A technology of polyurethane resin and phosphate ester, which is applied in the field of preparation of flame retardant resin materials, can solve the problems of decreased comprehensive performance of materials, poor dispersion of flame retardants, migration of flame retardants, etc., achieves excellent mechanical properties, improves mechanical properties and resistance Combustibility, the method is simple and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

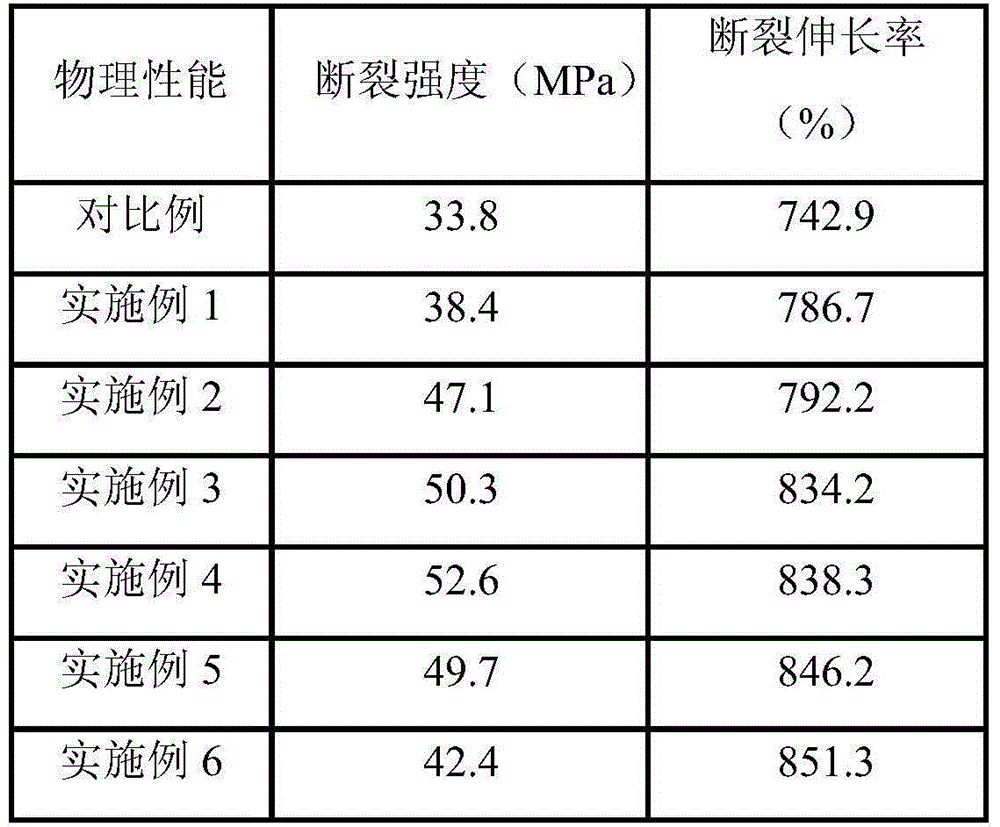

Examples

Embodiment 1

[0023] (1) Add 3.08g of β-cyclodextrin and 1.54g of resorcinol bis(diphenyl) phosphate to 30ml of DMAc solution, and mix thoroughly at 50°C for 1 hour to form β-cyclodextrin / RDP Complex;

[0024] (2) Set aside to settle, filter, vacuum dry, add 10ml of ethanol, wash excess RDP, and obtain β-cyclodextrin / RDP clathrate;

[0025] (3) Take 0.53g of β-cyclodextrin / RDP clathrate, add it to 35g of polyurethane resin with a solid content of 30%, add 16ml of DMAc to dissolve, stir well at room temperature, let stand, defoam, and shape to prepare polyurethane resin Combustion film and spline.

Embodiment 2

[0027] (1) Add 3.27g of β-cyclodextrin and 3.27g of resorcinol bis(diphenyl) phosphate to 30ml of DMAc solution, and mix thoroughly at 55°C for 2 hours to form β-cyclodextrin / RDP Complex;

[0028] (2) Set aside to settle, filter, vacuum dry, add 15ml of ethanol, wash excess RDP, and obtain β-cyclodextrin / RDP clathrate;

[0029] (3) Take 1.05g of β-cyclodextrin / RDP clathrate, add it to 35g of polyurethane resin with a solid content of 30%, add 14ml of DMAc to dissolve, stir well at room temperature, let stand, defoam, and shape to prepare polyurethane resin Combustion film and spline.

Embodiment 3

[0031] (1) Add 2.59g of β-cyclodextrin and 5.18g of resorcinol bis(diphenyl) phosphate to 25ml of DMAc solution and mix thoroughly at 60°C for 3 hours to form β-cyclodextrin / RDP Complex;

[0032] (2) Set aside to settle, filter, vacuum dry, add 25ml of ethanol, wash excess RDP, and obtain β-cyclodextrin / RDP clathrate;

[0033] (3) Take 1.58g of β-cyclodextrin / RDP clathrate, add it to 35g of polyurethane resin with a solid content of 30%, add 12ml of DMAc to dissolve, stir well at room temperature, let stand, defoam, and shape to prepare polyurethane resin Combustion film and spline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com