A kind of preparation method of room temperature self-healing polymer film

A polymer film and self-repairing technology, applied in the chemical industry, can solve problems such as poor mechanical properties, high repairing temperature, and difficult adjustment of mechanical properties, and achieve the effect of high yield and simple and easy-to-control manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

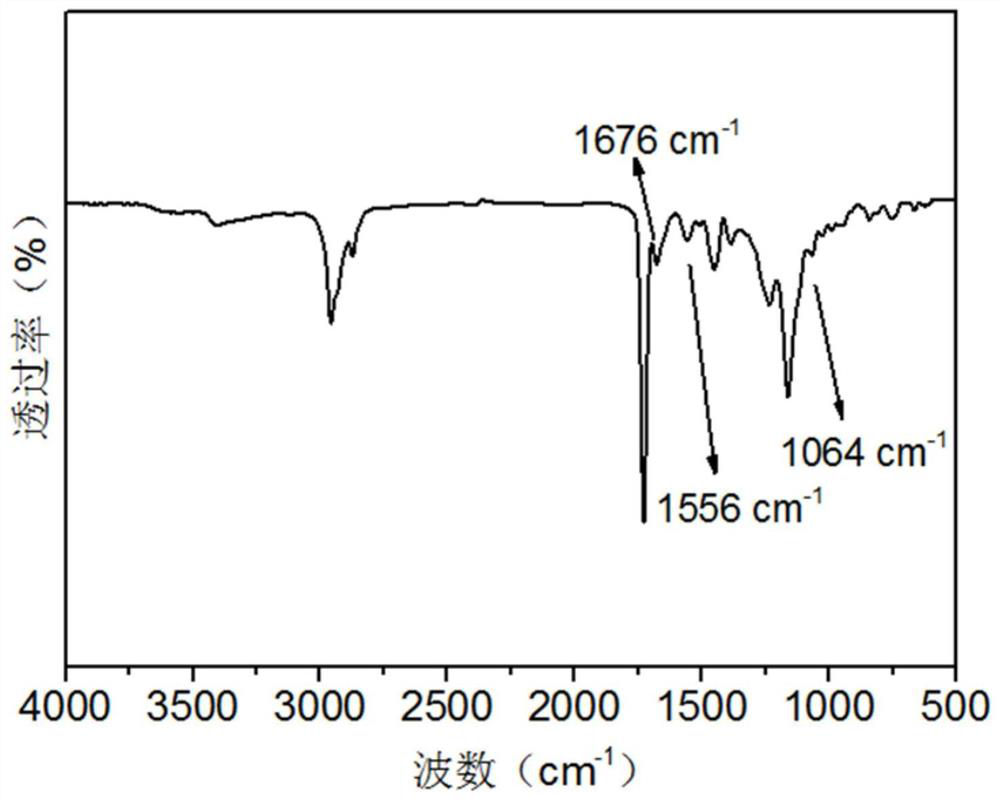

[0047] (1) Synthesis of functional monomers containing hydrogen bonds and metal coordination bonds: by mass, 45 grams of ethyl isocyanate acrylate are dissolved in acetonitrile, and 45 grams of 1-(3-aminopropyl) imidazoles are also dissolved in acetonitrile, The former was added dropwise to the latter, reacted for 4 hours at 40°C, cooled to room temperature after the reaction was completed, added a mixture of ethyl acetate and petroleum ether (V:V=5:1), extracted three times with the above mixture, Rotary steaming at 45°C for 0.5 h gave a transparent viscous oily liquid, which was a functional monomer containing hydrogen bonds and metal coordination bonds.

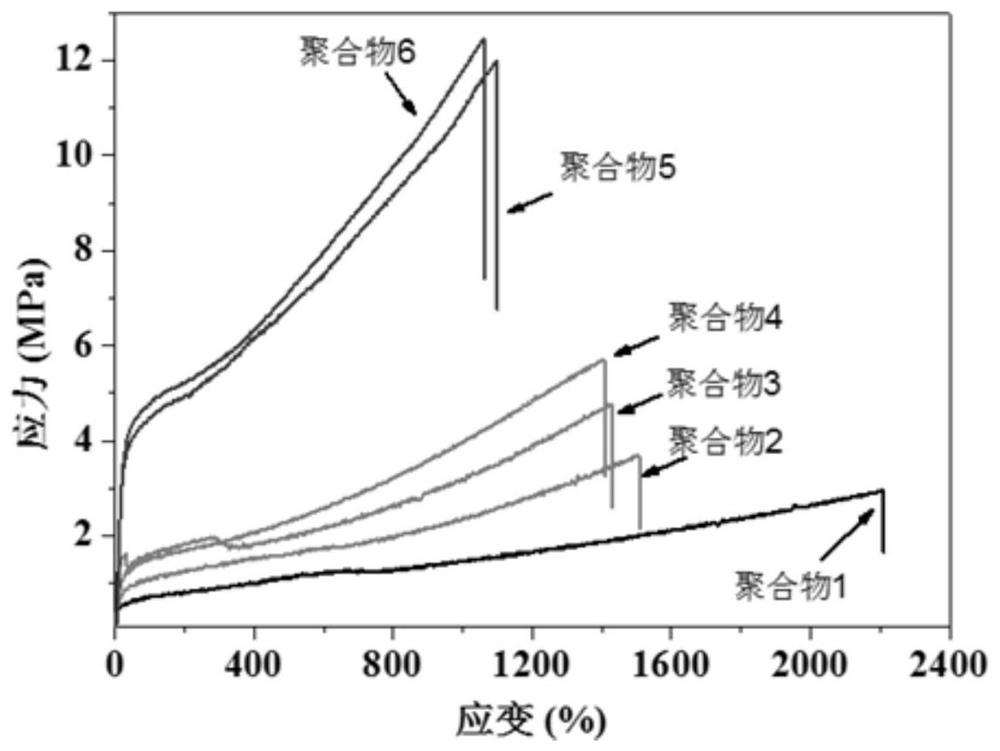

[0048] (2) Preparation of polymer materials containing hydrogen bonds and metal coordination bonds: by mass, get 5 grams of ethyl acrylate, 4 grams of methyl methacrylate, and the hydrogen bonds and metal coordination bonds obtained in step (1) 4 grams of reactive monomers, 0.02 grams of benzoyl peroxide, mixed in dimethyl...

Embodiment 2

[0053] (1) Synthesis of functional monomers containing hydrogen bonds and metal coordination bonds: by mass, 46 grams of ethyl isocyanate acrylate are dissolved in tetrahydrofuran, and 50 grams of 1-(3-aminopropyl) imidazoles are also dissolved in tetrahydrofuran, Add the former to the latter dropwise, react for 3 hours at 50°C, cool to room temperature after the reaction is complete, add a mixed solution of n-hexane and methyl tert-butyl ether (V:V=3:1), use the above mixed solution Extracted three times, then rotary evaporated at 50°C for 0.5h to obtain a transparent viscous oily liquid, which is a functional monomer containing hydrogen bonds and metal coordination bonds.

[0054] (2) Preparation of polymer materials containing hydrogen bonds and metal coordination bonds: by mass, get 4 grams of n-butyl acrylate, 2 grams of ethyl methacrylate, hydrogen bonds and metal coordination bonds obtained in step (1) 3 parts of functional monomers, 0.025 g of azobisisobutyronitrile we...

Embodiment 3

[0064] (1) Synthesis of functional monomers containing hydrogen bonds and metal coordination bonds: by mass, 40 grams of ethyl isocyanate acrylate are dissolved in toluene, and 50 grams of 1-(3-aminopropyl) imidazoles are also dissolved in toluene, Add the former to the latter dropwise, react for 5 hours at 30°C, cool to room temperature after the reaction is complete, add a mixture of butyl acetate and dimethyl sulfoxide (V:V=2:1), use the above mixture Extract three times, and spin evaporate at 45°C for 0.5h to obtain a transparent viscous oily liquid, which is a functional monomer containing hydrogen bonds and metal coordination bonds.

[0065] (2) Preparation of polymer materials containing hydrogen bonds and metal coordination bonds: by mass, get 4.5 grams of isobutyl acrylate, 3 grams of n-propyl methacrylate, and the hydrogen bonds and metal coordination bonds obtained in step (1) 3 grams of key functional monomers, 0.05 grams of azobisisoheptanonitrile were mixed in N,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com