Method for synthesizing silicon oxide thin sheet with three dimension continuous nano pore structure

A technology of nanopores and silicon oxide, which is applied in the direction of silicon oxide, silicon dioxide, chemical instruments and methods, etc., can solve the problem of weak surface activity of long-chain alkyl primary amines, poor solubility in water, and poor shape control of products. Too ideal and other problems, to achieve the effect of short diffusion path, simple and easy to control method, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

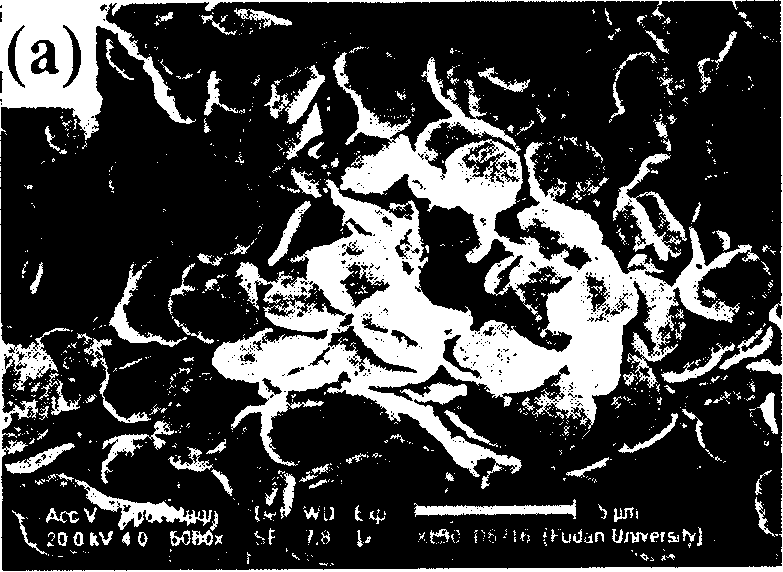

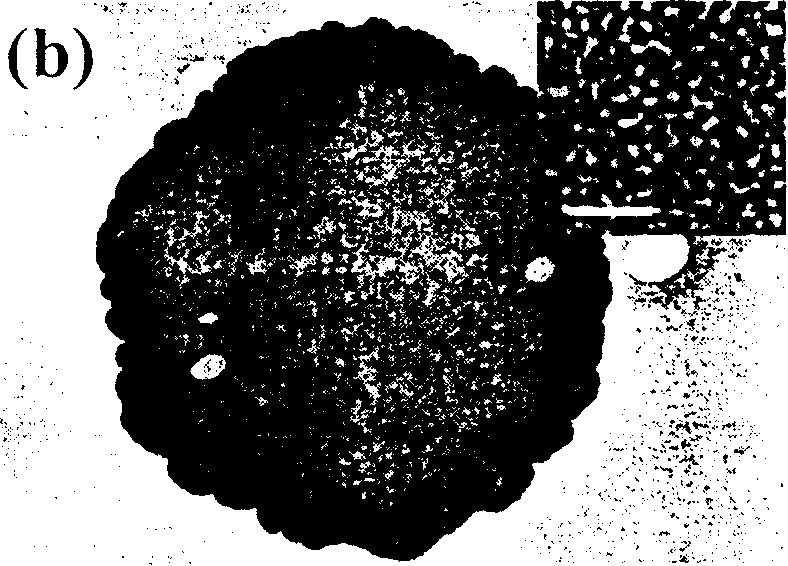

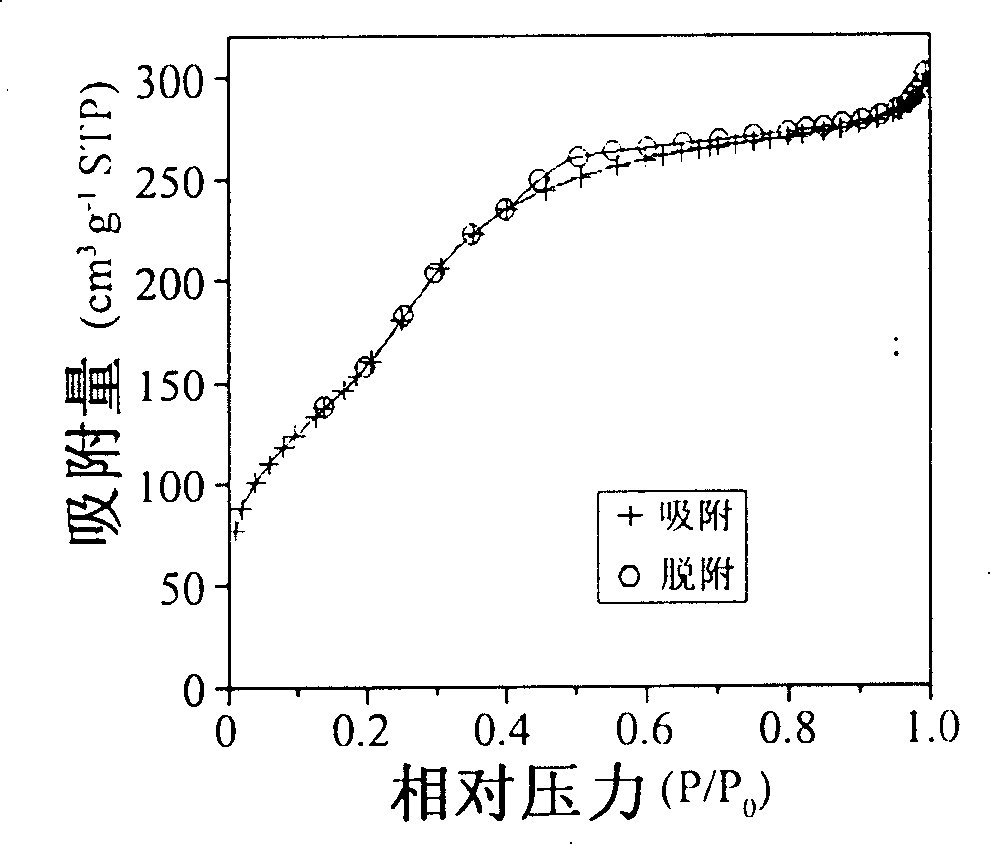

[0027] Weigh 0.6 g of hexadecylamine and dissolve it in 60 ml of ethanol, add 60 ml of water and 2.0 g of concentrated ammonia water, and stir until hexadecylamine is completely dissolved. Under vigorous stirring, 2.4 g of ethyl orthosilicate was added, and the stirring was continued until the ethyl orthosilicate was evenly dispersed. After the stirring was stopped, it was left at room temperature for 12 hours, filtered with suction, washed with ethanol, and dried overnight at 90°C. Finally, the templating agent was removed by firing at 600°C for 4 hours in an air atmosphere. The product is marked as A 1 .

example 2~6

[0029] Synthesize by the method described in example 1, but the addition of ethyl orthosilicate changes to 0.6, 1.2, 1.8, 3.0 and 3.6 grams, the proportioning and reaction conditions of other reactants all do not change. The obtained product is denoted as A 2 、A 3 、A 4 、A 5 and A 6 .

example 7~10

[0031] Synthesize according to the method described in example 1, but the add-on of hexadecylamine is changed to 0.2, 0.3, 0.4 and 0.5 gram, the proportioning of other reactants and reaction condition all do not change. The obtained product is denoted as A 7 、A 8 、A 9 and A 10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com