Halogen-free flame retardant polylactic acid composite material

A composite material, polylactic acid technology, applied in the field of halogen-free flame-retardant polylactic acid composite materials, to achieve the effect of maintaining the physical and mechanical properties of the material, reducing the amount of addition, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

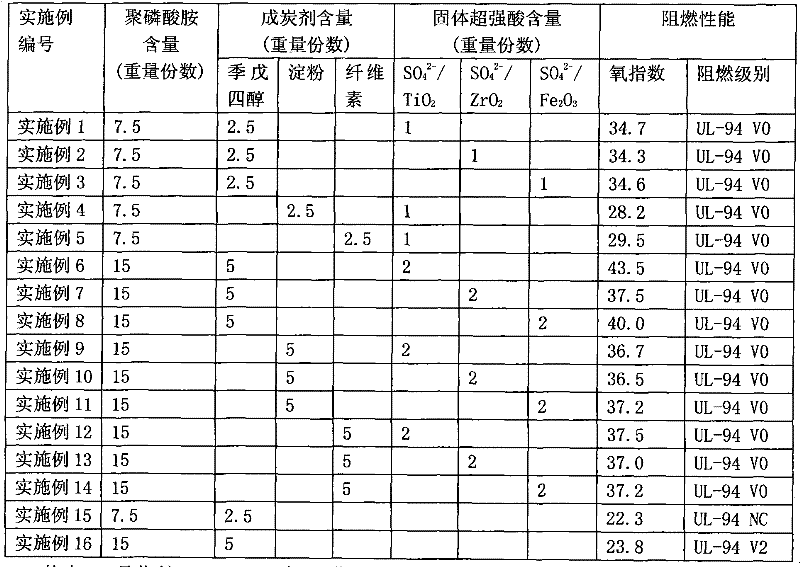

Embodiment 1

[0018] SO 4 2- / M x o y type solid superacid is solid superacid SO 4 2- / TiO 2 , antioxidant is the trade mark and is the commercialized antioxidant of 1010, and anti-melting dripping agent is SN3300 anti-melting dripping agent, and nucleating agent is talcum powder, and charring agent is pentaerythritol. Taking polylactic acid resin as the body, adding a mixture of ammonium polyphosphate and char-forming agent, solid super acid SO 4 2- / TiO 2 , antioxidant, nucleating agent and anti-melt-dripping agent, and obtain halogen-free flame-retardant polylactic acid composite material through melt blending. In terms of parts by weight, the total parts by weight is 100 parts, the mixture of ammonium polyphosphate and charcoal agent accounts for 10 parts, wherein ammonium polyphosphate accounts for 7.5 parts, charcoal agent accounts for 2.5 parts, SO 4 2- / M x o y Type solid super acid accounts for 1 part, antioxidant accounts for 0.2 part, nucleating agent accounts for 0.5...

Embodiment 2

[0020] SO 4 2- / M x o y type solid superacid is solid superacid SO 4 2- / ZrO 2 , all the other ingredients and content are identical with embodiment 1.

Embodiment 3

[0022] SO 4 2- / M x o y type solid superacid is solid superacid SO 4 2- / Fe 2 o 3 , all the other ingredients and content are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com