Regenerated polypropylene environment-friendly modified material and preparation method thereof

A technology for recycled polypropylene and modified materials, which is applied in the field of recycled polypropylene environmentally friendly modified materials and its preparation, can solve problems such as waste, resource pollution, inability to degrade and rot, and achieve material cost saving, low cost, and less impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

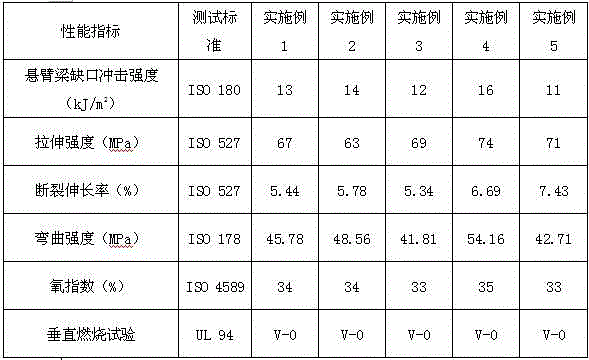

Examples

Embodiment 1

[0051] A recycled polypropylene environmentally friendly modified material, consisting of the following substances by weight:

[0052] Polypropylene recycled material 100 parts

[0053] 10 parts glass fiber

[0054] Nitrogen-phosphorus compound intumescent flame retardant 30 parts

[0055] Flame retardant synergist 0.3 parts

[0056] Impact modifier 4 parts

[0057] Antioxidant 2 parts

[0058] 0.5 parts of coupling agent

[0059] The flame retardant synergist is silicon dioxide. The impact modifier is recycled rubber particles, and the particle size of the recycled rubber particles is 3-8 μm. Nitrogen-phosphorus compound intumescent flame retardant is compounded by ammonium polyphosphate, pentaerythritol and melamine according to the mass ratio of 2:1:0.5.

[0060] In the present invention, silicon dioxide is added as the flame retardant synergist of the nitrogen-phosphorus compound intumescent flame retardant, the oxygen index of the flame retardant system can reach 36%...

Embodiment 2

[0069] A recycled polypropylene environmentally friendly modified material, consisting of the following substances by weight:

[0070] Polypropylene recycled material 100 parts

[0071] 12 parts glass fiber

[0072] Nitrogen-phosphorus compound intumescent flame retardant 35 parts

[0073] Flame retardant synergist 0.3 part

[0074] Impact modifier 8 parts

[0075] Antioxidant 1 part

[0076] 0.1 parts of coupling agent,

[0077] The flame retardant synergist is silicon dioxide. The impact modifier is recycled rubber particles, and the particle size of the recycled rubber particles is 3-8 μm. Nitrogen-phosphorus compound intumescent flame retardant is compounded by ammonium polyphosphate, pentaerythritol and melamine according to the mass ratio of 1.5:1:0.3.

[0078] In the present invention, silicon dioxide is added as the flame retardant synergist of the nitrogen-phosphorus compound intumescent flame retardant, the oxygen index of the flame retardant system can reach ...

Embodiment 3

[0087] A recycled polypropylene environmentally friendly modified material, consisting of the following substances by weight:

[0088] Polypropylene recycled material 100 parts

[0089] 11 parts glass fiber

[0090] Nitrogen and phosphorus compound intumescent flame retardant 34 parts

[0091] Flame retardant synergist 0.5 parts

[0092] Impact modifier 10 parts

[0093] Antioxidant 2 parts

[0094] 0.4 parts of coupling agent,

[0095] The flame retardant synergist is silicon dioxide. The impact modifier is recycled rubber particles, and the particle size of the recycled rubber particles is 3-8 μm. Nitrogen-phosphorus compound intumescent flame retardant is compounded by ammonium polyphosphate, pentaerythritol and melamine according to the mass ratio of 1.5:1:0.8.

[0096] In the present invention, silicon dioxide is added as the flame retardant synergist of the nitrogen-phosphorus compound intumescent flame retardant, the oxygen index of the flame retardant system can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com