General white master batch and its preparation method

A technology of white masterbatch and heat stabilizer, applied in the field of general white masterbatch and its preparation, can solve the problems of low whiteness and reduced impact performance, and achieve the effects of high whiteness, excellent impact performance and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

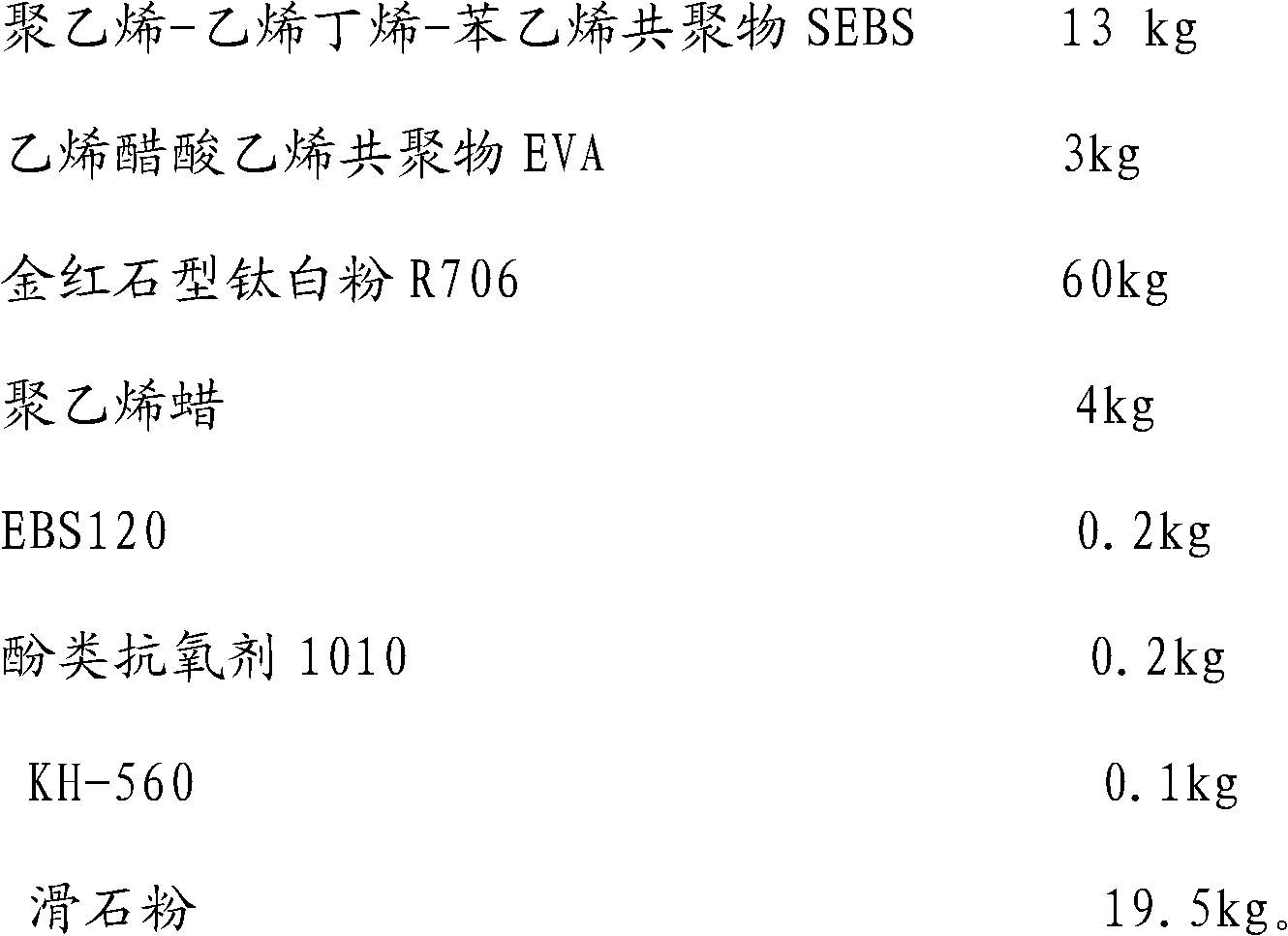

Embodiment 1

[0043] The proportioning ratio of each component is (total amount is 100kg):

[0044]

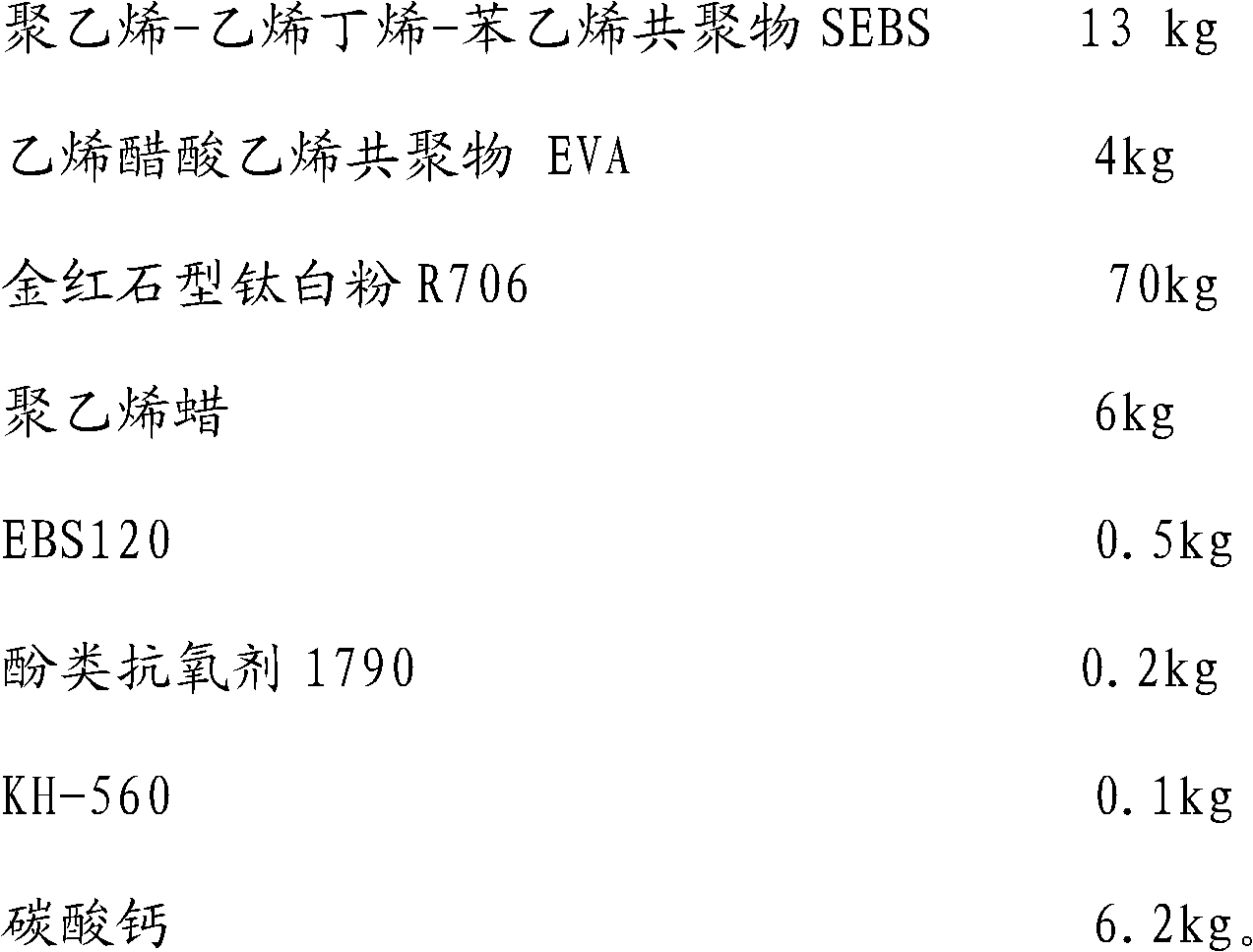

Embodiment 2

[0046] The proportioning ratio of each component is (total amount is 100kg):

[0047]

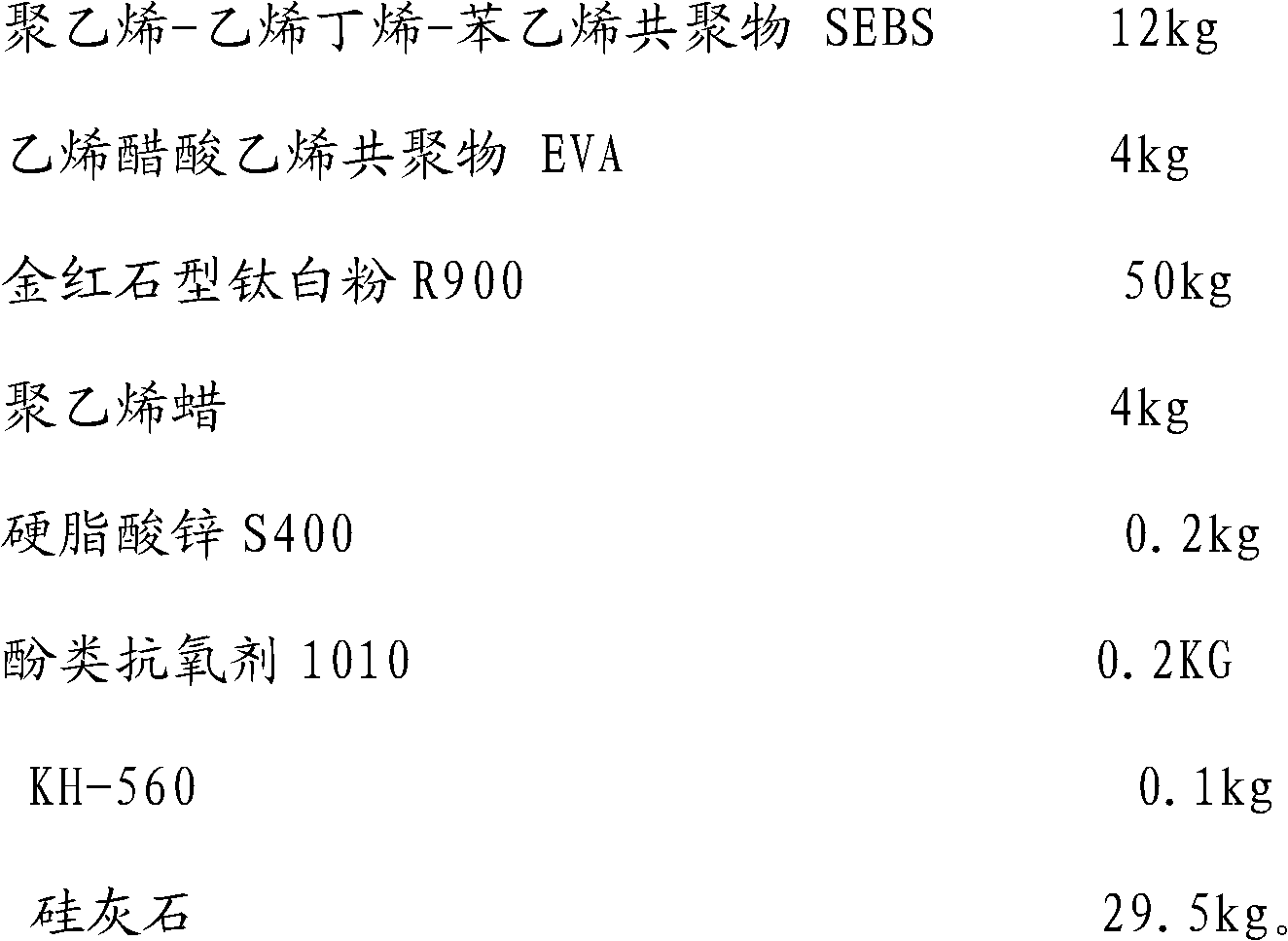

Embodiment 3

[0049] The proportioning ratio of each component is (total amount is 100kg):

[0050]

[0051]Under normal temperature and pressure, prepare 100kg micro-foaming universal white masterbatch. The preparation process is as follows: after mixing the components in proportion, pre-mix the components in the mixer for 5 minutes at a low speed, and then mix them at a high speed for 15 minutes. Finally, the fully mixed materials are melt-blended in a twin-screw extruder, the temperature is controlled at 200°C, and the screw speed is 200r / min. The pigment is uniformly dispersed in the carrier resin through shearing and mixing of the screw, and then the manufacturing process is carried out. The color masterbatch of the present invention is obtained through the processes of granulation, drying, packaging and the like.

[0052] In order to compare the advantages of the present invention and the prior art, comparative experiments are carried out according to the formulations of the compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com