Polymer/organic montmorillonite nano composite flame-proof masterbatch, its preparing method and application

An organic montmorillonite and nanocomposite technology, which is applied in the field of polymer/organic montmorillonite nanocomposite flame retardant masterbatch and its preparation, can solve the problems of unfavorable large-scale industrial production, flying dust, affecting flame retardant performance, etc., to achieve Good application and promotion prospects, simple processing technology, and the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of Example 1 PBA / OMMT Nanocomposite Flame Retardant Masterbatch

[0040] Add 600 milliliters (ml) of water, 6.0 grams (g) of sodium lauryl sulfate, 2.0 g of ammonium persulfate and 90 g of organic montmorillonite (OMMT) modified by octadecyltrimethylammonium chloride into three ports In the flask, stir in a water bath at 35°C for 5 hours, then raise the temperature of the water bath to 80°C, add 90 g of butyl acrylate to the three-necked flask under stirring, and polymerize at 80°C for 6 hours, and the reaction product Pour into a beaker, add an appropriate amount of distilled water, stir evenly, let stand until the reactants are separated, discard the upper layer of clear water, filter the lower layer under reduced pressure, and vacuum-dry the obtained solid matter at 60°C to constant weight to obtain the content of OMMT About 50% polybutylacrylate / organic montmorillonite (PBA / OMMT) nanocomposite flame retardant masterbatch, denoted as PBA / OMMT-50.

[0041...

Embodiment 2

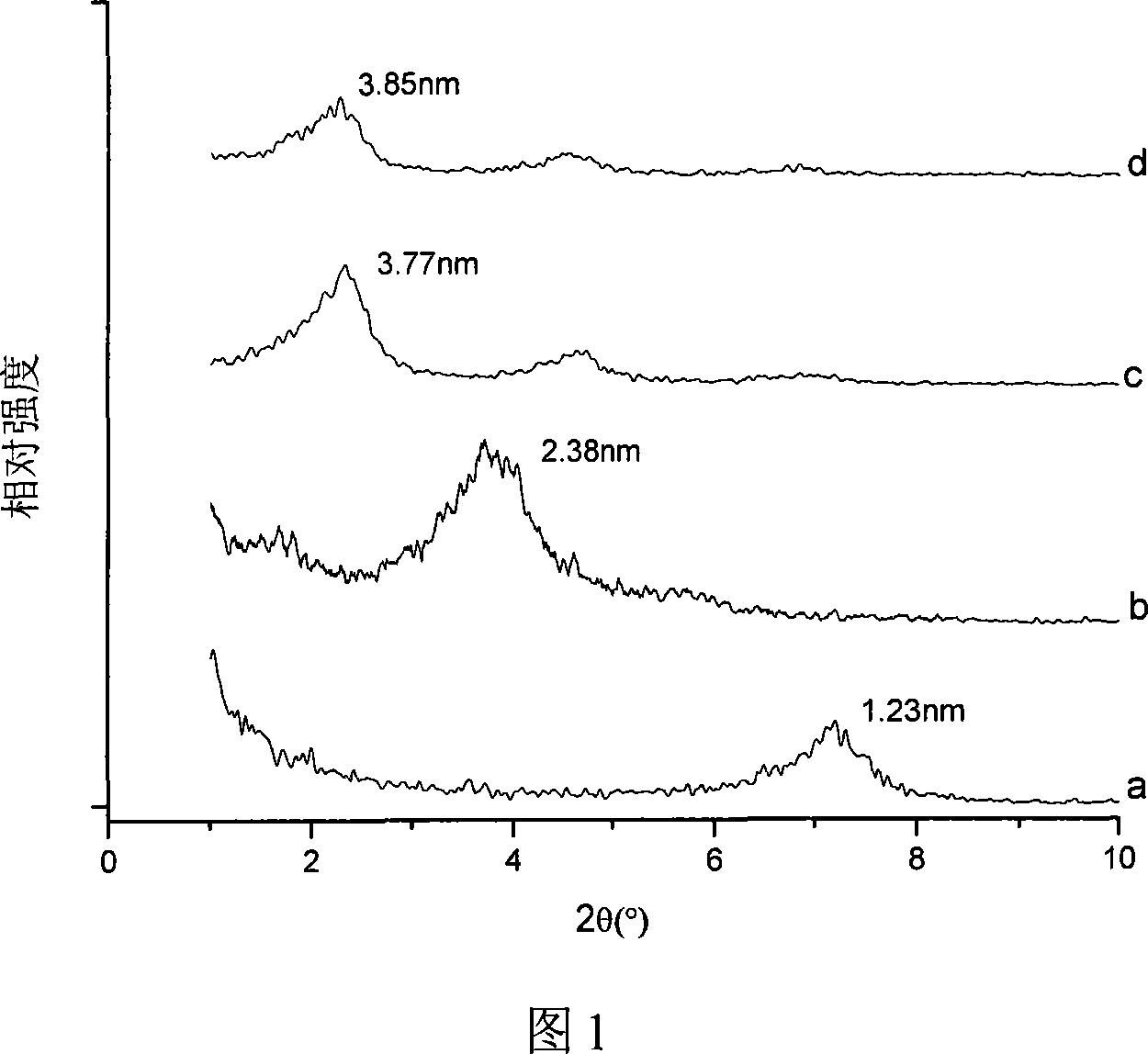

[0049] The preparation method and reaction conditions of the PBA / OMMT nanocomposite flame retardant masterbatch of the present invention are as embodiment 1, the OMMT consumption is reduced to 60g, namely the PBA / OMMT nanocomposite flameretardant masterbatch that makes OMMT content is about 40%, Denoted as PBA / OMMT-40. It can be seen from Figure 1(d) that the layer spacing of montmorillonite is 3.85nm, which is close to that of PBA / OMMT-50.

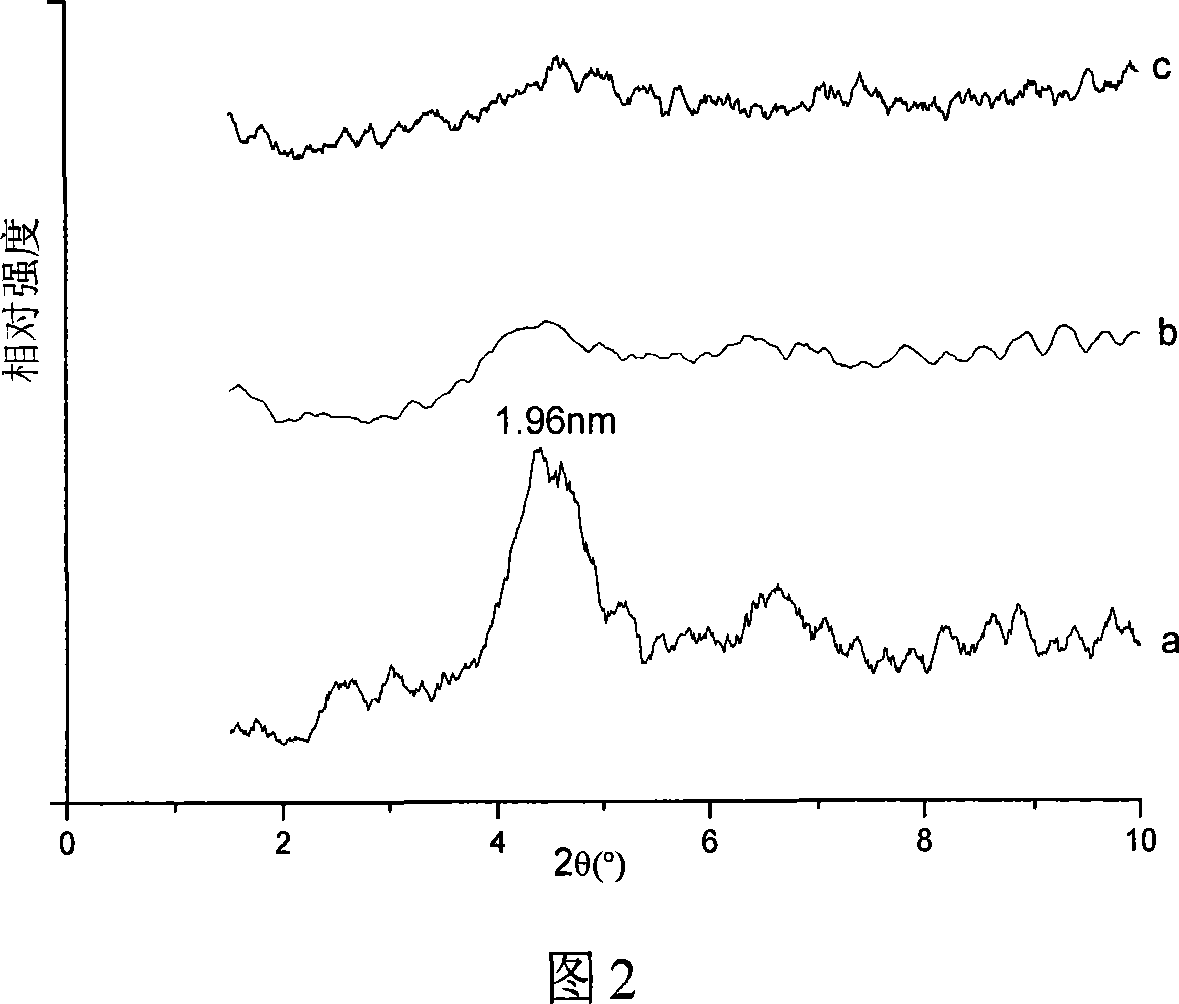

[0050] Fig. 2(c) is the XRD spectrum of flame retardant ABS with OMMT content of 3% prepared by PBA / OMMT-40 masterbatch dispersion method. The results are similar to those in Figure 2(b), indicating that the montmorillonite sheets were exfoliated in ABS and dispersed uniformly at the nanoscale, forming an exfoliated ABS / OMMT nanocomposite.

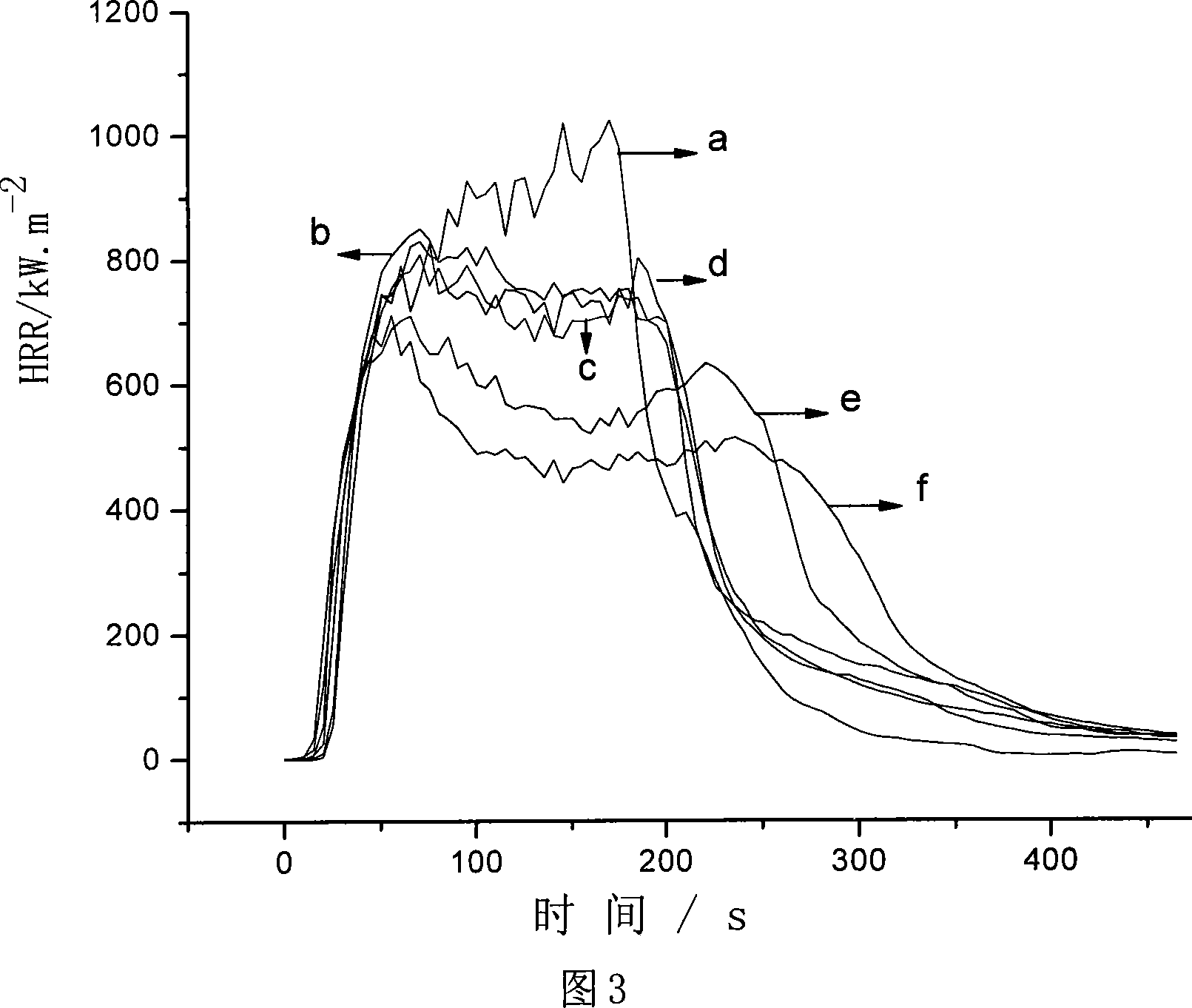

[0051] It can be seen from Figure 3(d) that the PHHR and mHRR of flame-retardant ABS prepared from PBA / OMMT-40 masterbatch with 3% OMMT content are 825.2kW.m -2 and 358.8Kw.m -2 , respectively decr...

Embodiment 3

[0053] According to the method and conditions of Example 1, PBA / OMMT-40 nanocomposite flame retardant masterbatch was used to prepare flame retardant ABS. Flame-retardant ABS with 5% and 7% OMMT contents were prepared by changing the amount of PBA / OMMT-40.

[0054] It can be seen from Figures 3(d), 3(e), and 3(f) that as the OMMT content increases from 3% to 5% and 7%, the HRR curve of flame-retardant ABS gradually becomes gentle, and the PHHR changes from 825.2 kW.m -2 Respectively decreased to 709.5kW.m -2 and 710.8kW.m -2 , indicating that the increase of OMMT content is beneficial to improve the flame retardant effect, but when its content increases to 5%, PHRR no longer decreases. In addition, when the amount of OMMT increased from 3% to 5% and 7%, the tensile strength of the obtained flame-retardant ABS decreased from 44.7MPa to 39.5MPa and 36.9MPa, respectively, and the impact strength decreased from 8.0kJ.m -2 Respectively down to 7.8kJ.m -2 and 5.7kJ.m -2 , indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com