Low activation temperature adhesive composition with high peel strength and cohesive failure

a technology of adhesive composition and low activation temperature, which is applied in the direction of synthetic resin layered products, transportation and packaging, chemistry apparatus and processes, etc., can solve the problems of requiring very costly release films, most current adhesives tend to significantly lose their bond strength, and prior art patents are not satisfactory in every asp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

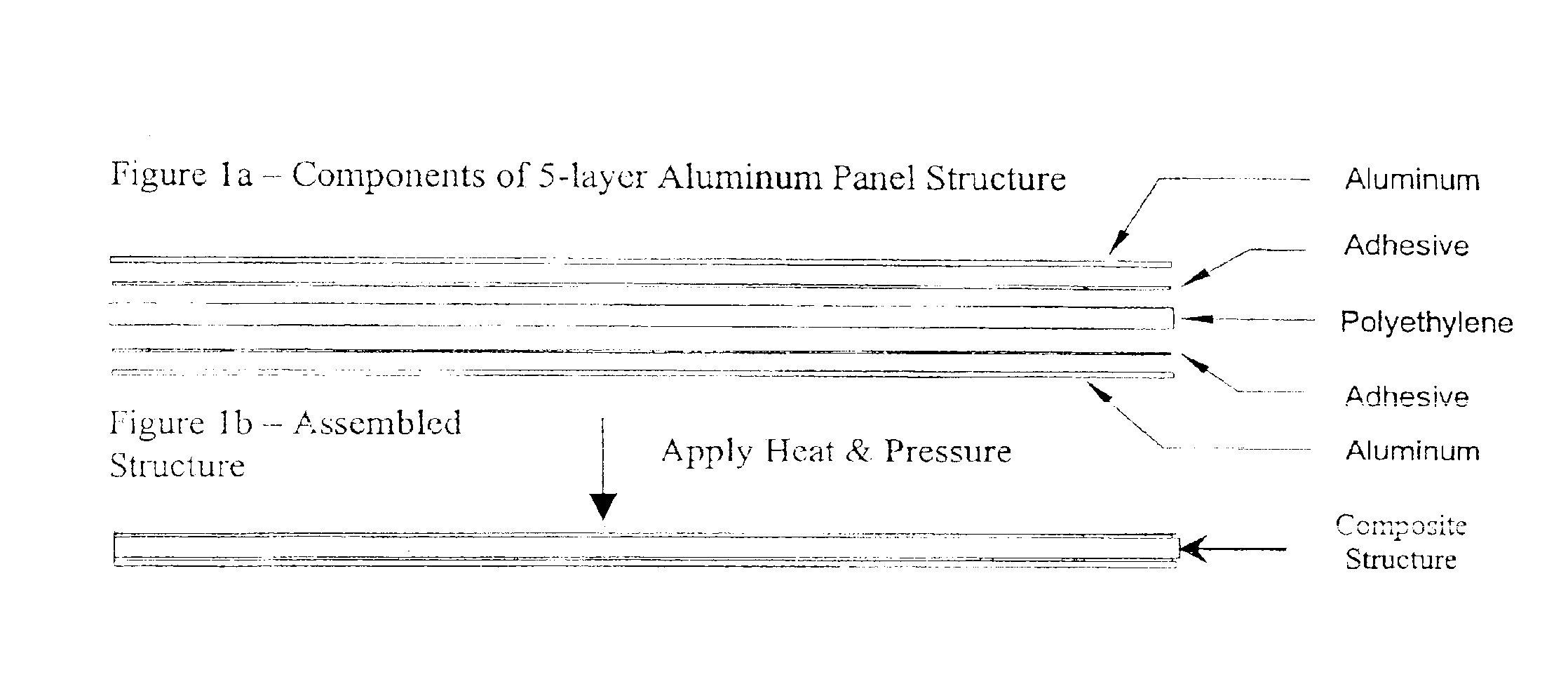

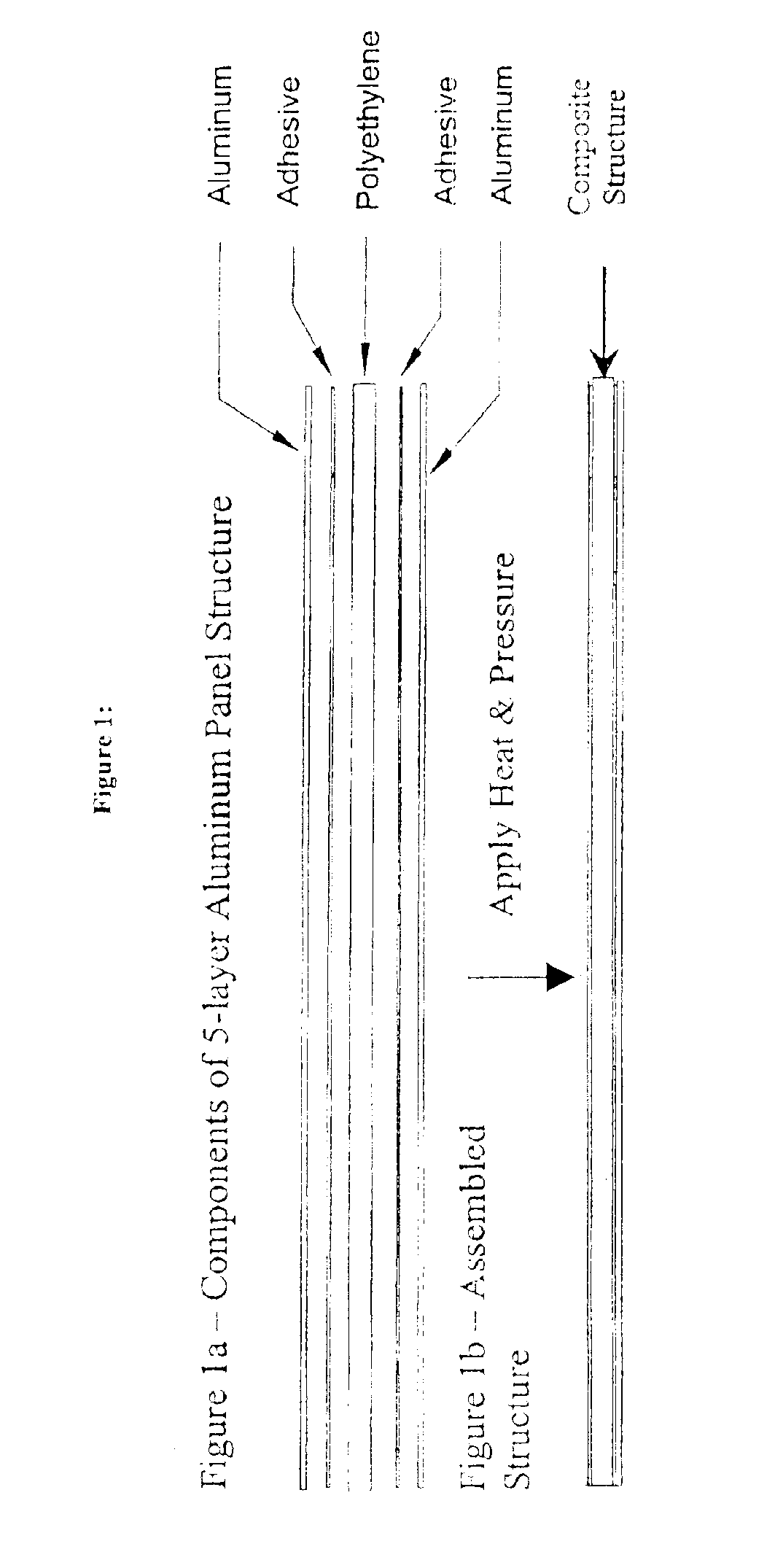

Table 1 shows the compositions 1A, 1B and 1C at 0 wt %, 10 wt % and 20 wt % High Impact Polystyrene (“HIPS”) respectively. These compositions were dry-blended initially and fed to a small co-rotating twin-screw extruder. The melt-compounded materials were pelletized and then blown into film with an average thickness of about 75 microns. The films were subsequently used as adhesive layers to make a 5 layer composite structure as shown in FIGS. 1a and 1b. The aluminium was aludyne treated and had a thickness of 0.38 mm. The polyethylene core used was low-density polyethylene (LDPE) sheet, 2 mm thick.

The lamination of the structures were carried out in a electrically heated press as follows (FIGS. 1a and 1b):1—Preheat the 5-layer structure for 4.5 min. @ 100° C.2—Apply pressure of 5 kgf / cm2 at 135° C. for 20 seconds.3—Release the pressure and leave the composite in the press for an additional 1.5 min. @ 135° C.4—Air cool the sample to room temperature.

The composite structure was then t...

example 2

Samples were prepared as described in Example 1 with the exception that co-extruded blown films of polyethylene / Adhesive were made and substituted for a pure adhesive film in order to reduce the cost of the adhesive used. The compositions 2A, 2B and 2C are co-extruded with a linear low density polyethylene (LLDPE) producing LLDPE-Adhesive (each layer being 25 micron thick). The results are summarized in Table 2. The co-extruded films generally result in lower peel strength as can be seen comparing 1C vs. 2A (29.8 vs. 16.5 kgf / 25 mm, respectively) but they are still functional. The addition of high impact polystyrene at 30 wt % level (2C) appears to lower the peel strength. This latter composition is still functional though not optimal.

TABLE 22-Layer Ethylene Vinyl Acetate (EVA) / Polyethylene based AdhesivesIDComp. (a)Comp. (b)Comp. (c)Comp. (d)Comp. (e)Reel StrengthFailureNo.Wt %Wt %Wt %Wt %Wt %kgf / 25 mmMode2A29.930.020.020.00.116.5100% Cohesive2B44.920.015.020.00 117.5100% Cohesive2...

example 3

In this example, compositions were made using metallocene linear low-density polyethylene as the base resin. Table 3 summarises the compositions. Samples 3A, 3B and 3C were prepared as those described in Examples 1 and 2. The last two compositions 3D and 3E were prepared in a 2-step process, in order to more closely simulate an actual commercial production. Adhesives of 3D and 3E were initially laminated to aluminium at a temperature of 149° C., using a pressure of 8.5 kgf / cm2 for 30 seconds. These pre-laminated aluminium sheets were then pressed with a pre-heated LDPE core at 132° C., using a pressure of 8.5 kgf / cm2 for 10 seconds. The peel testing was performed at a 90° angle as opposed to the 180° angle used in the other examples. Composition 3D is a repeat of 3C and is used to compare the performance between the different lamination and testing methods. Sample 3D represents much lower peel strength than 3C due to 180° peel test vs. a 90° peel for sample 3C.

Once again increasing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com