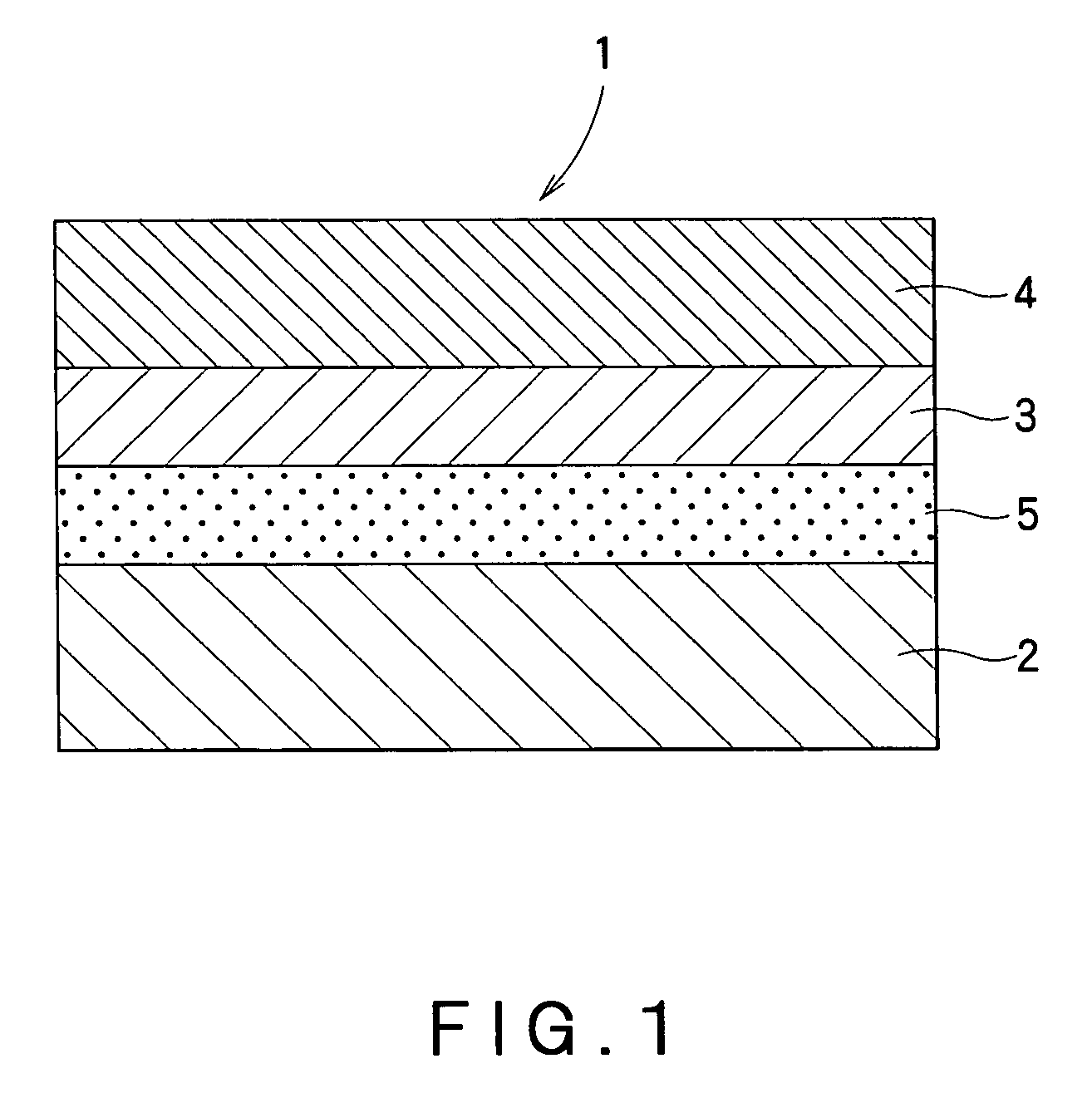

Antireflection laminate

- Summary

- Abstract

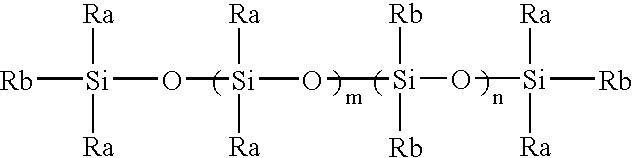

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0180] Preparation of composition for low refractive index layer formation

[0181] The following ingredients were mixed together according to the following formulation to prepare a composition for low refractive index layer formation.

Surface treated hollow silica sol12.85pts. wt.(hollow silica fine particle dispersion liquid IA)Pentaerithritol triacrylate (PETA)1.43pts. wt.Irgacure 907 (tradename, manufactured by0.1pt. wt.Ciba Specialty Chemicals, K.K.)F3035 (tradename, manufactured by0.4pt. wt.Nippon Oils & Fats Co., Ltd.)Methyl isobutyl ketone85.22pts. wt.

Preparation of composition for hardcoat layer formation

[0182] The following ingredients were mixed together according to the following formulation to prepare a composition for hardcoat layer formation.

Pentaerithritol triacrylate (PETA) 5.0 pts. wt.Irgacure 184 (tradename, manufactured by 0.25 pts. wt.Ciba Specialty Chemicals, K.K.)Methyl isobutyl ketone94.75 pts. wt.

[0183] Preparation of base material / hardcoat layer / low refr...

example 2

[0186] A hardcoat layer and a low refractive index layer were formed in the same manner as in Example 1, except that the composition for low refractive index layer formation used in Example 1 was changed as follows. Thus, a laminate of Example 2 was prepared.

Surface treated hollow silica sol12.85pts. wt.(hollow silica fine particle dispersion liquid IB)Pentaerithritol triacrylate (PETA)1.43pts. wt.Irgacure 907 (tradename, manufactured by0.1pt. wt.Ciba Specialty Chemicals, K.K.)F3035 (tradename, manufactured by0.4pt. wt.Nippon Oils & Fats Co., Ltd.)Methyl isobutyl ketone85.22pts. wt.

example 3

[0187] A hardcoat layer and a low refractive index layer were formed in the same manner as in Example 1, except that the composition for low refractive index layer formation used in Example 1 was changed as follows. Thus, a laminate of Example 3 was prepared.

Surface treated hollow silica sol12.85pts. wt.(hollow silica fine particle dispersion liquid IB)Dipentaerythritol hexaacrylate (DPHA)1.43pts. wt.Irgacure 907 (tradename, manufactured by0.1pt. wt.Ciba Specialty Chemicals, K.K.)F3035 (tradename, manufactured by0.4pt. wt.Nippon Oils & Fats Co., Ltd.)Methyl isobutyl ketone85.22pts. wt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com