Actuating means able to be activated by fluid action

a technology of actuators and actuators, applied in fluid-pressure actuators, positive displacement liquid engines, flexible member pumps, etc., can solve problems such as increased design complexity, problem of contractile hoses being pulled out of clamping gaps, and difficult to secure the connection between contractile hoses and head pieces, and achieves reliable connection and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

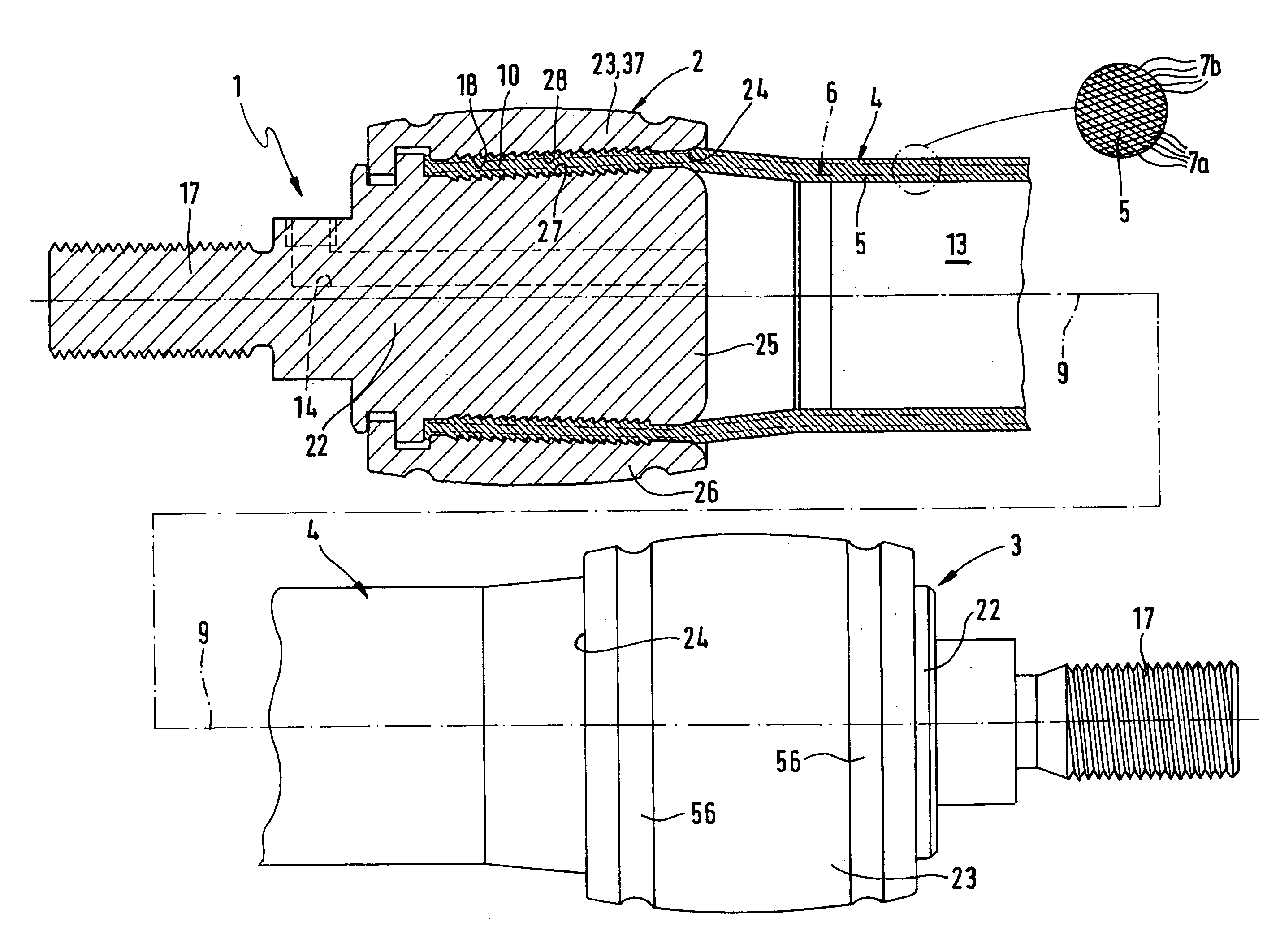

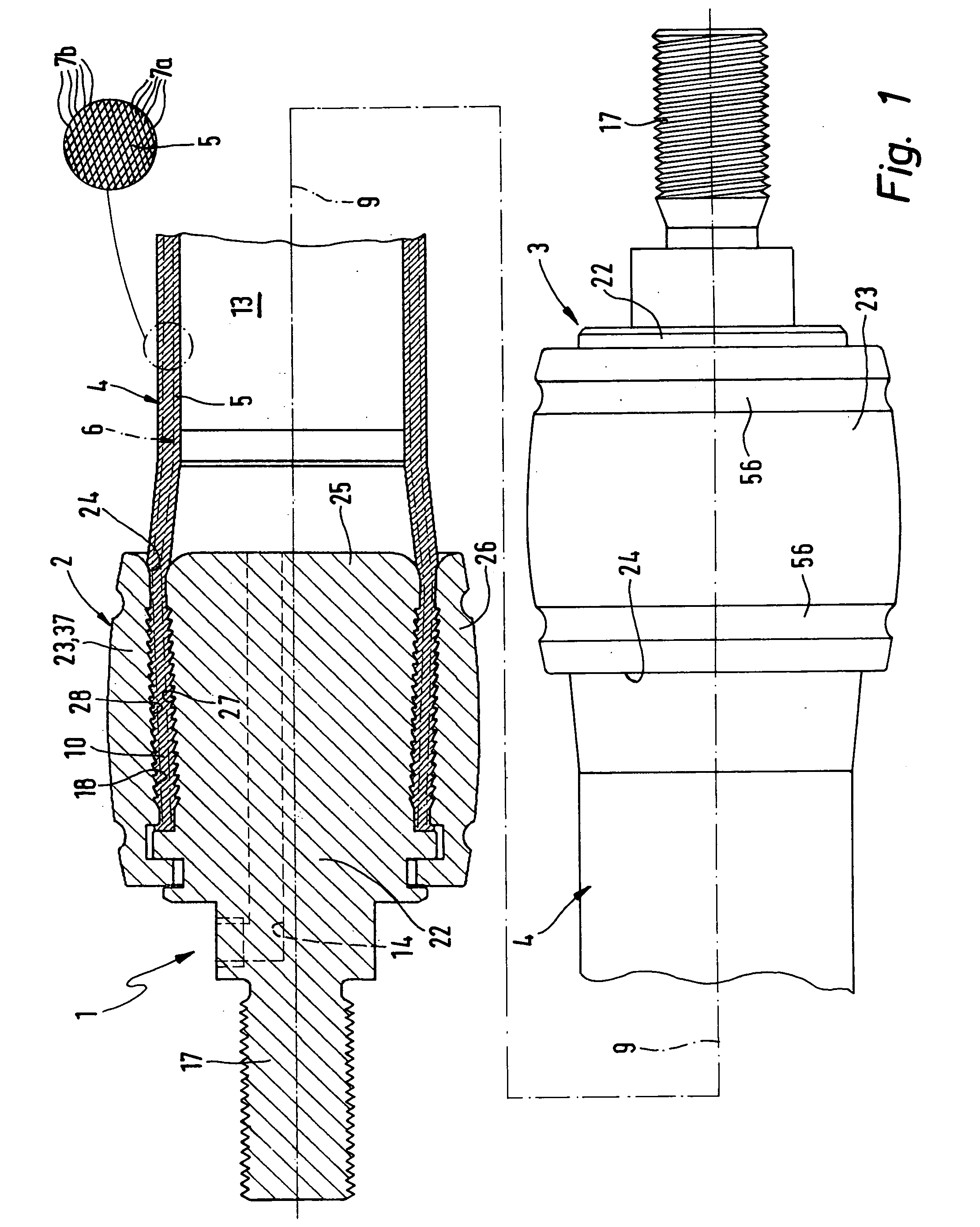

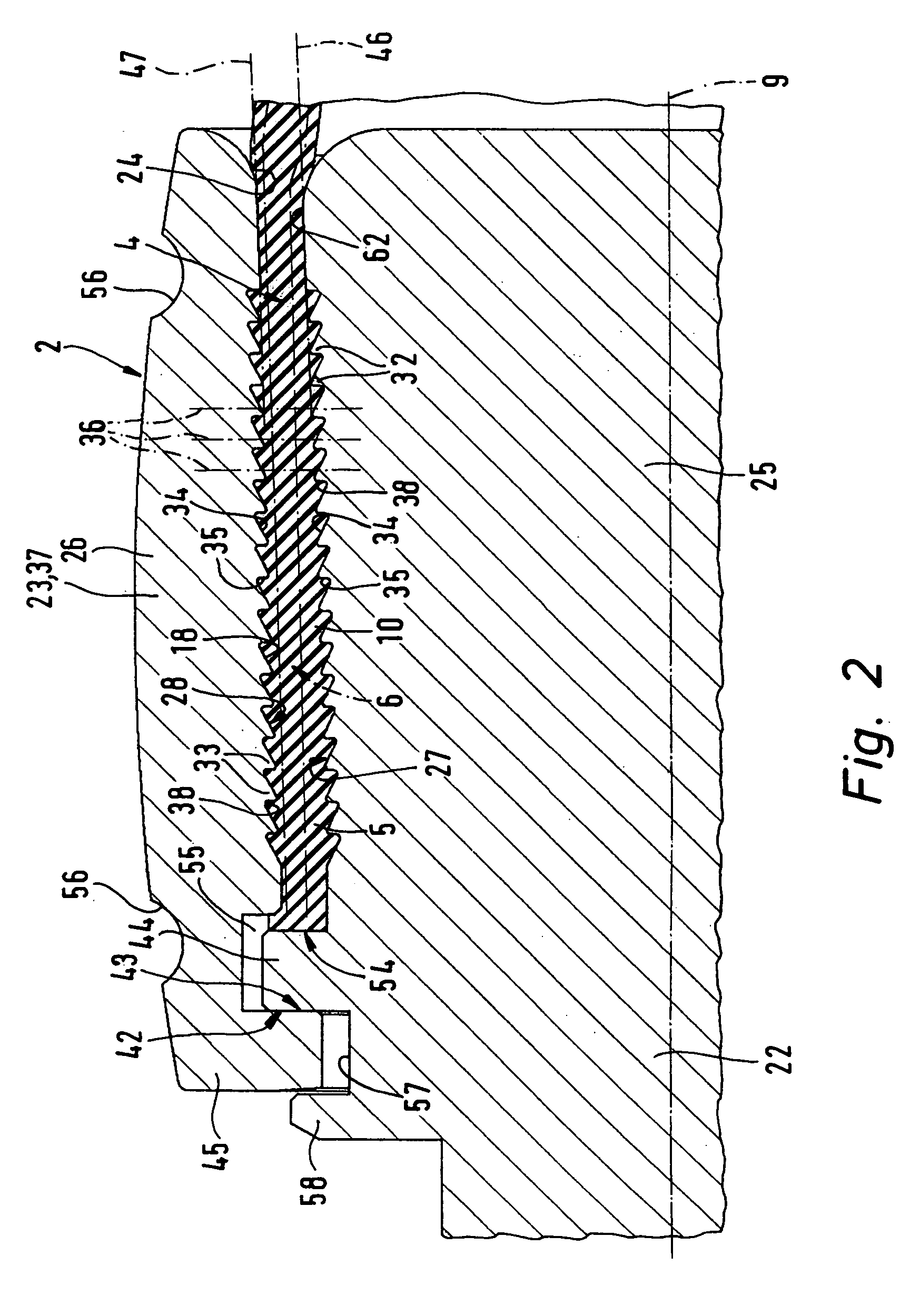

[0022] The actuating means 1 illustrated in the drawings by way of example comprises two first and second head pieces 2 and 3 arranged at an axial distance apart, which are permanently connected together by way of a linearly extending contractile hose 4. At least in the deactivated state of the actuating means 1 the contractile hose 4 preferably has an essentially tubular form.

[0023] As regards details the contractile hose 3 of the working example possesses an elongated hose body 5 consisting of a material with rubber elastic properties. As a material more particularly rubber itself or another elastomeric material is employed. In the wall of the hose body 5 a strand structure 6 is embedded, which is for the sake of simplicity only indicated in chained lines, which is completely surrounded by the material of the hose body 5 and is coaxial to the body.

[0024] Preferably the structural design of the contractile hose 4 is the same as that described in the said patent publication WO 00 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com