Preparation method of high-purity grafted functionalized copolymer

A technology of copolymerization and functionalization, which is applied in the field of preparation of high-purity graft functionalized copolymers, can solve problems such as short extraction time, large environmental pollution, and low vacuum degree of equipment, and achieves reduced purification costs, simple preparation process, The effect of low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of high-purity polypropylene graft maleic anhydride graft copolymer:

[0037] Prepare crude polypropylene grafted maleic anhydride copolymer with twin-screw extruder melt grafting according to the following formula:

[0038] (1) 100 parts of polypropylene (2) 10100.3 parts of antioxidant

[0039] (3) Ultraviolet absorber UV-5310.5 parts (4) Butanone 0.5 parts

[0040] (5) 0.0003 parts of azobisisobutyronitrile (6) 2.0 parts of maleic anhydride

[0041]The crude polypropylene-grafted maleic anhydride copolymer prepared by a twin-screw extruder was placed in an autoclave whose temperature was previously constant to 50°C. Use a booster pump to inject carbon dioxide gas to a pressure of 30MPa, so that the carbon dioxide enters a supercritical state. Hold the pressure for 60 minutes. Then quickly release the pressure, and the pressure release time is 3 seconds. Accurately weigh the polypropylene-grafted maleic anhydride copolymer purified by supercritical ca...

Embodiment 2

[0043] Preparation of high-purity ethylene-vinyl alcohol copolymer grafted with glycidyl methacrylate copolymer.

[0044] Prepare crude ethylene-vinyl alcohol copolymer grafted glycidyl methacrylate copolymer with twin-screw extruder melt grafting according to the following formula:

[0045] (1) 100 parts of ethylene-vinyl alcohol copolymer (2) 10760.3 parts of antioxidant

[0046] (3) Ultraviolet absorber UV-3290.5 parts (4) Acetone 0.5 parts

[0047] (5) 0.0002 parts of benzoyl peroxide (6) 1.8 parts of glycidyl methacrylate

[0048] The crude ethylene-vinyl alcohol copolymer grafted with glycidyl methacrylate copolymer prepared by a twin-screw extruder was placed in an autoclave whose temperature had been constant to 75° C. in advance. Use a booster pump to inject carbon dioxide gas to a pressure of 15MPa to make carbon dioxide enter a supercritical state. Hold the pressure for 90 minutes. Then quickly release the pressure, and the pressure release time is 3 seconds. A...

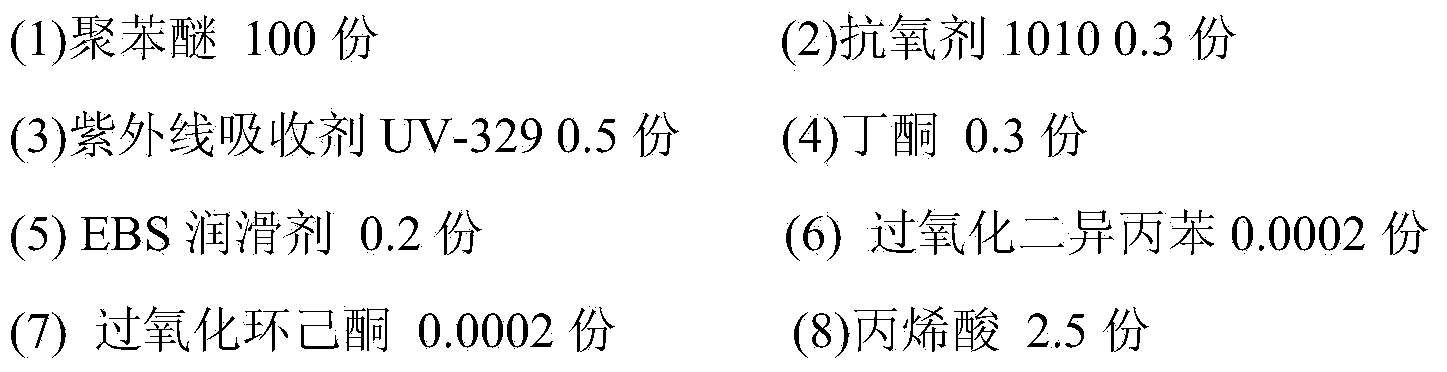

Embodiment 3

[0050] Preparation of high-purity ethylene-acrylic acid copolymer grafted styrene copolymer:

[0051] Prepare crude ethylene-acrylic acid copolymer grafted styrene copolymer with twin-screw extruder melt grafting according to the following formula:

[0052] (1) 100 parts of ethylene-acrylic acid copolymer (2) 2250.3 parts of antioxidant

[0053] (3) UV absorber 70030.5 parts (4) EBS lubricant 0.5 parts

[0054] (5) 0.0004 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (6) 4.0 parts of styrene

[0055] The ethylene-acrylic acid copolymer grafted styrene copolymer prepared by a twin-screw extruder was placed in an autoclave whose temperature was previously constant to 100°C. Use a booster pump to inject carbon dioxide gas to a pressure of 21MPa to make carbon dioxide enter a supercritical state. Hold the pressure for 90 minutes. Then quickly release the pressure, and the pressure release time is 4 seconds. Accurately weigh the ethylene-acrylic acid copolymer grafted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com