Production method of non-oriented electrical steel coating semi-processed product

A technology of oriented electrical steel and production method, which is applied in the field of electrical steel production, can solve problems such as inability to obtain excellent electromagnetic properties, and achieve the effects of retaining excellent characteristics, continuous and efficient production, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

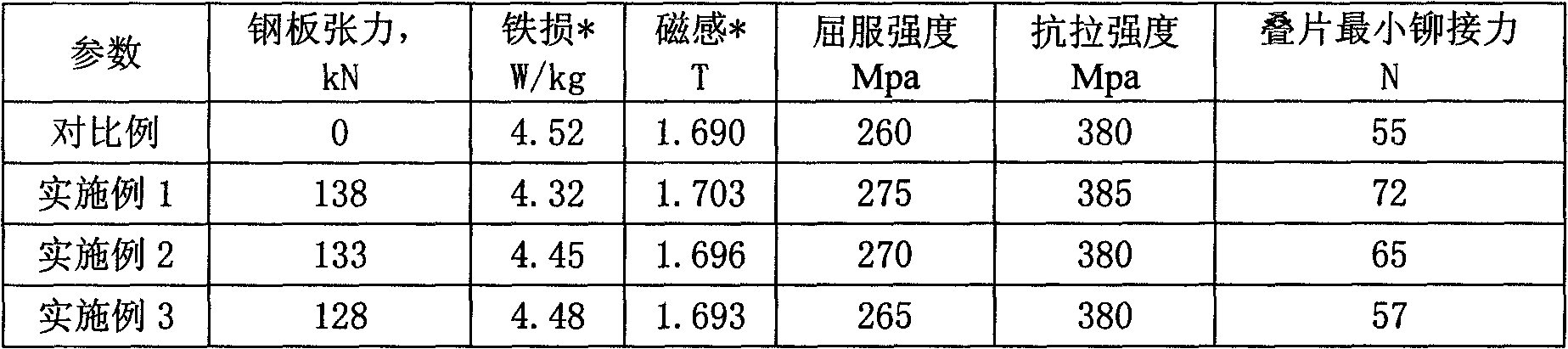

[0010] The present invention will be further described below by way of examples.

[0011] The chemical composition of the cold-rolled non-oriented silicon steel in the embodiment of the present invention is: C: 0.004%, Si: 1.14%, Mn: 0.33%, P: 0.12%, S: 0.002%, Als: 0.28%. Its main production process is: converter smelting, RH vacuum refining, steel billet heated at 1120°C and then rolled into 2.2mm thick hot-rolled sheet, hot-rolled sheet coiling temperature is 710°C, hot-rolled sheet cold-rolled to 0.5mm, cold-rolled sheet Annealed at 910°C×2min. The yield strength of the finished plate is 260Mpa, and the width of the finished plate is 1030mm. In the embodiment of the present invention, a group of five-roller tension leveling devices are added between the uncoiling and coiling process sections of the recoil operation line, and the tension F applied to the finished steel plate satisfies: S×Rp 0.2 ≤F≤1.2×S×Rp 0.2 , such as the pulling force F=1.1×0.0005×1.030×245×1000000=13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com