Patents

Literature

31results about How to "Extended range of materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

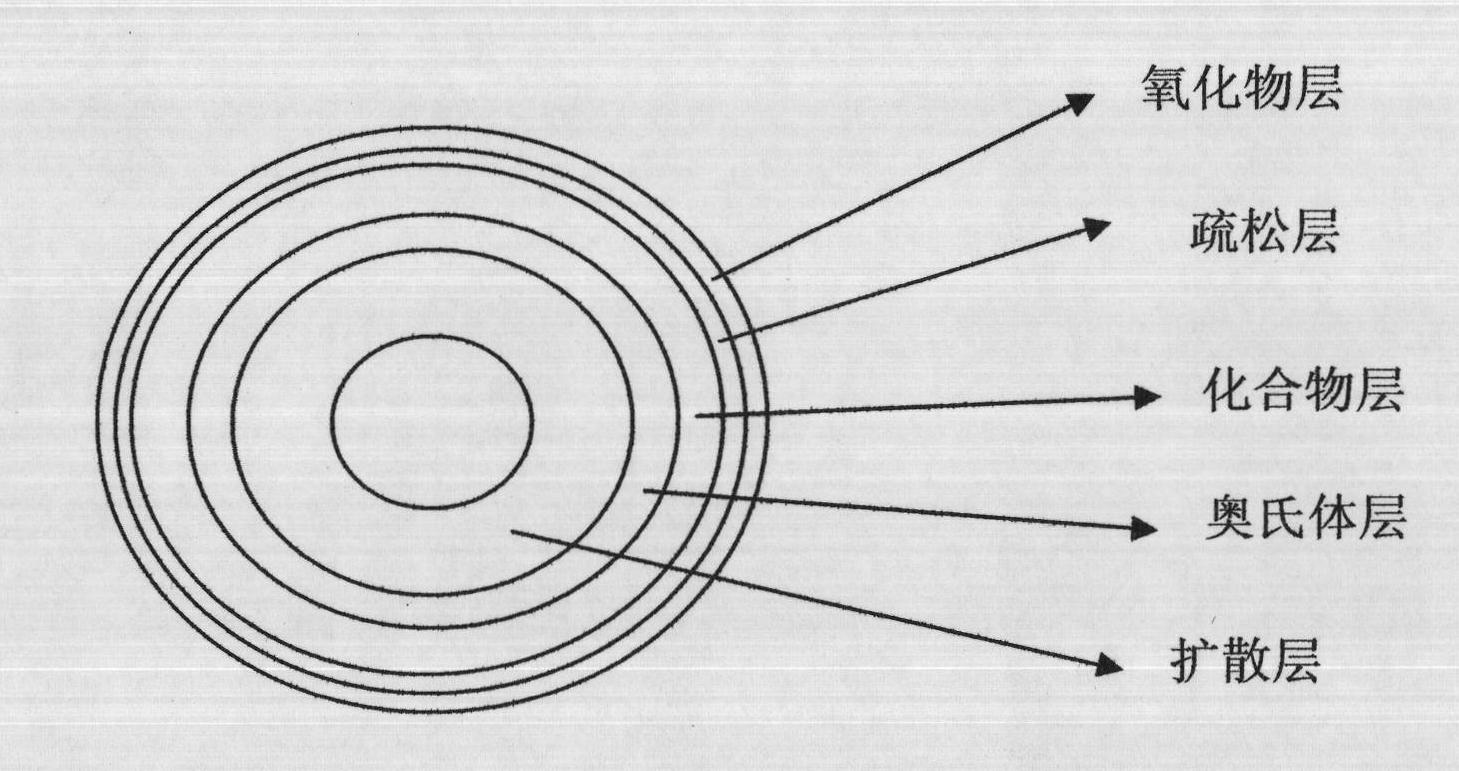

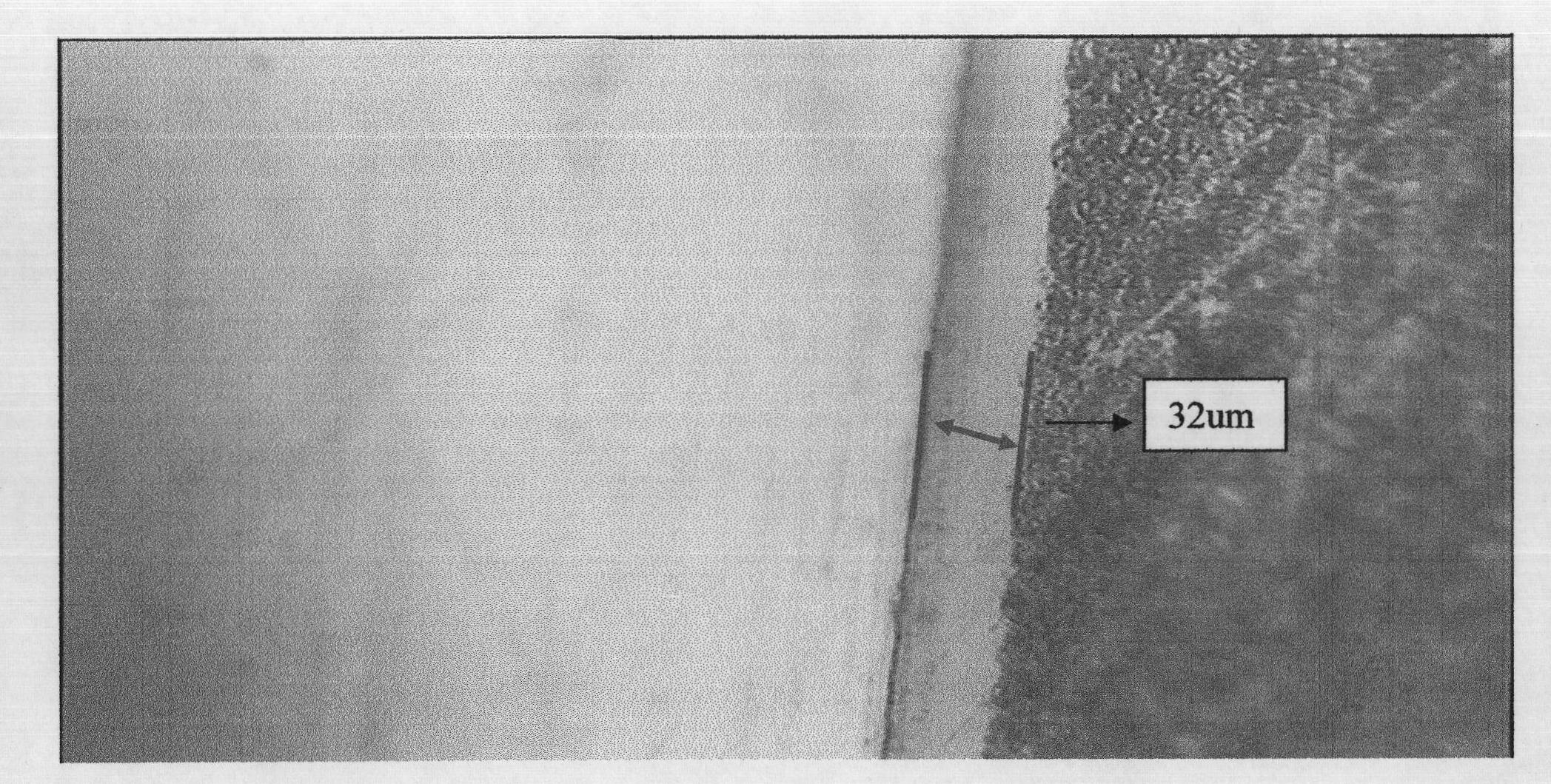

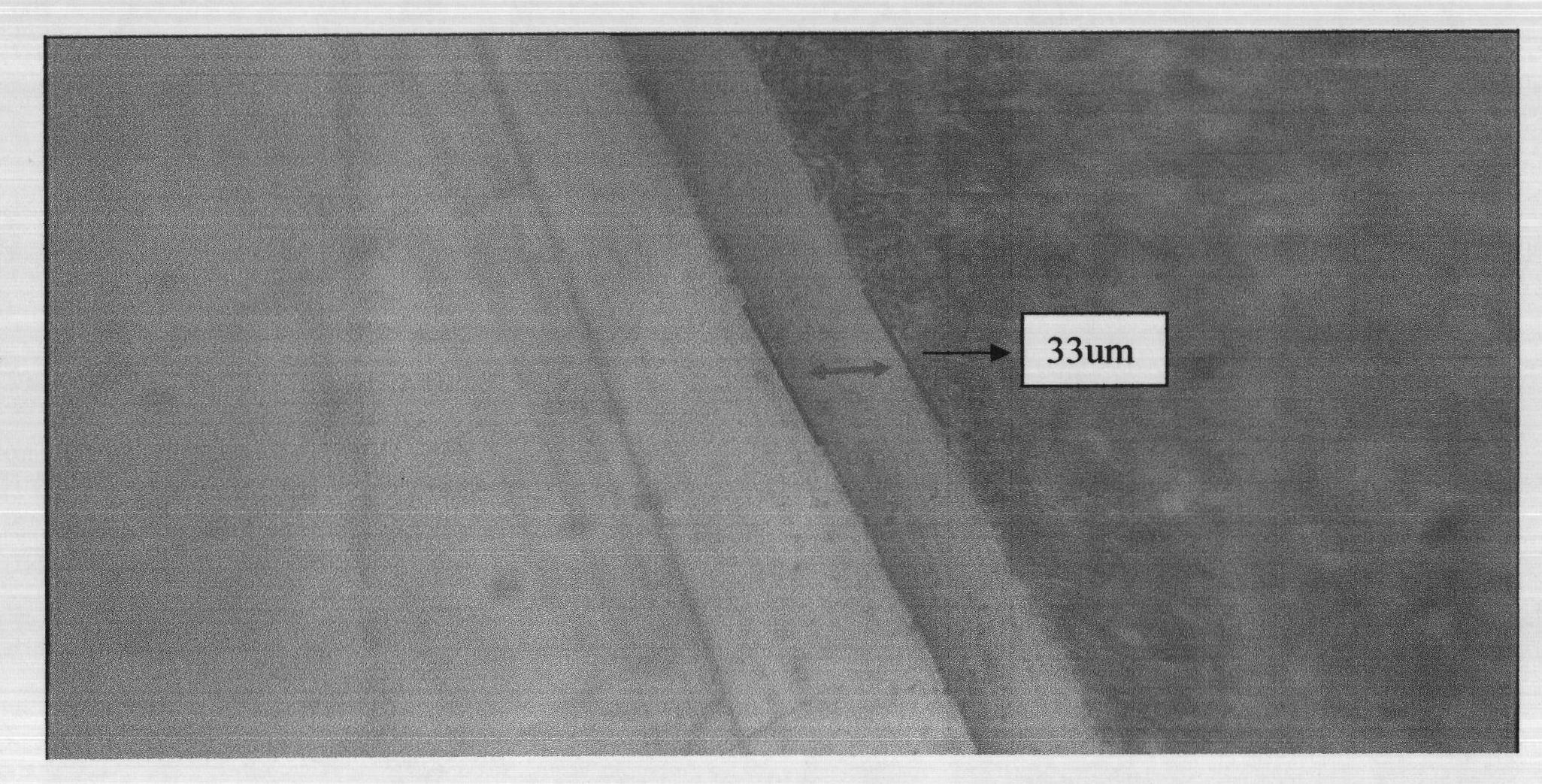

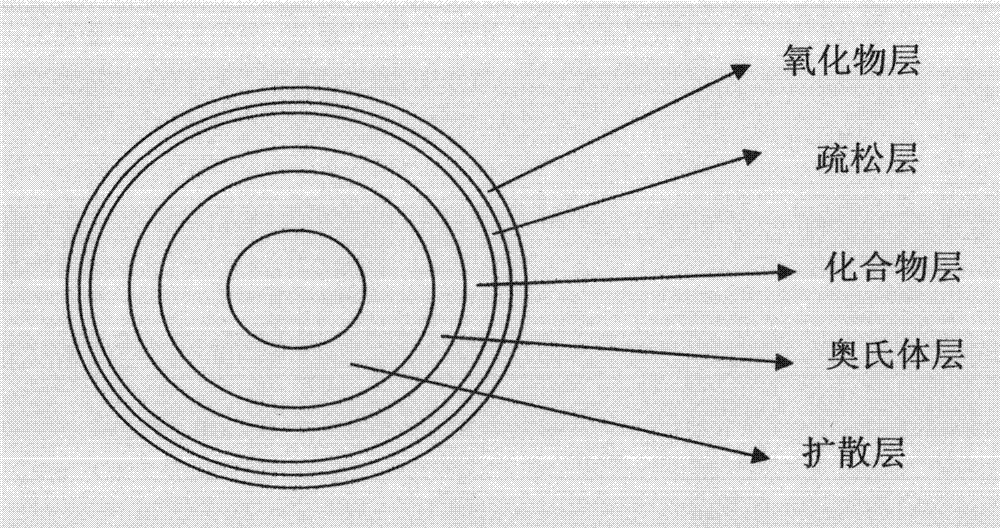

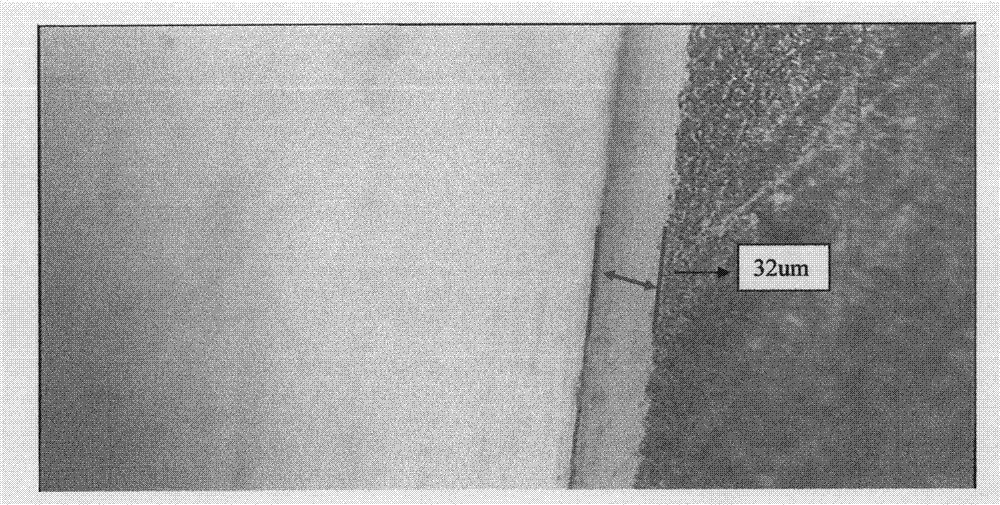

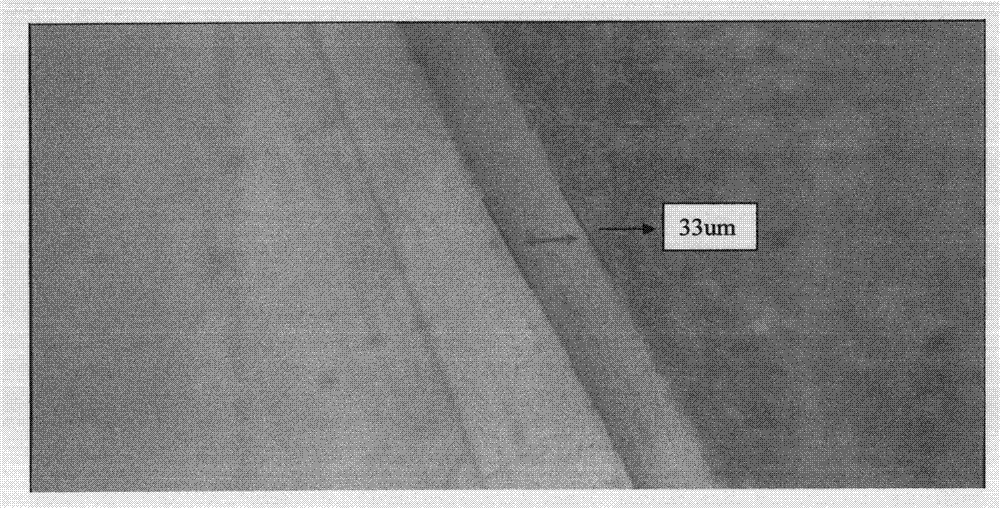

Piston rod and production method thereof as well as carbonitriding agent for piston rod surface treatment

The invention relates to a piston rod and a production method thereof as well as a carbonitriding agent for piston rod surface treatment. The carbonitriding agent comprises the following components by weight percent: 20-24% of urea, 13-15% of thiourea, 10-14% of barium acetate, 24-27% of calcium carbonate, 22-26% of barium carbonate and 4-10% of lithium carbonate. The carbonitriding layer tissue comprises an oxide layer, a tectorium, a compound layer, an Austria layer and a diffusion layer. The carbonitriding agent has the beneficial effects of simple formula and low cost; the piston rod produced by using the carbonitriding agent is smooth in surface, low in roughness and is airproof, the piston rod compound carbonitriding layer is more than 32mu m in thickness and has the characteristics of high corrosion resistance and abrasion resistance, low rejection ratio and long service life; in the piston rod production process, thermal treatment and anti-corrosion treatment are completed once, treatment temperature is between 600 DEG C-700 DEG C, the piston rod production process has the advantage of optimizing the machining process; and nitriding time is shortened to 30-50 minutes, production period is shortened, and production cost is reduced.

Owner:QINGDAO ZHANGSHI MACHINERY

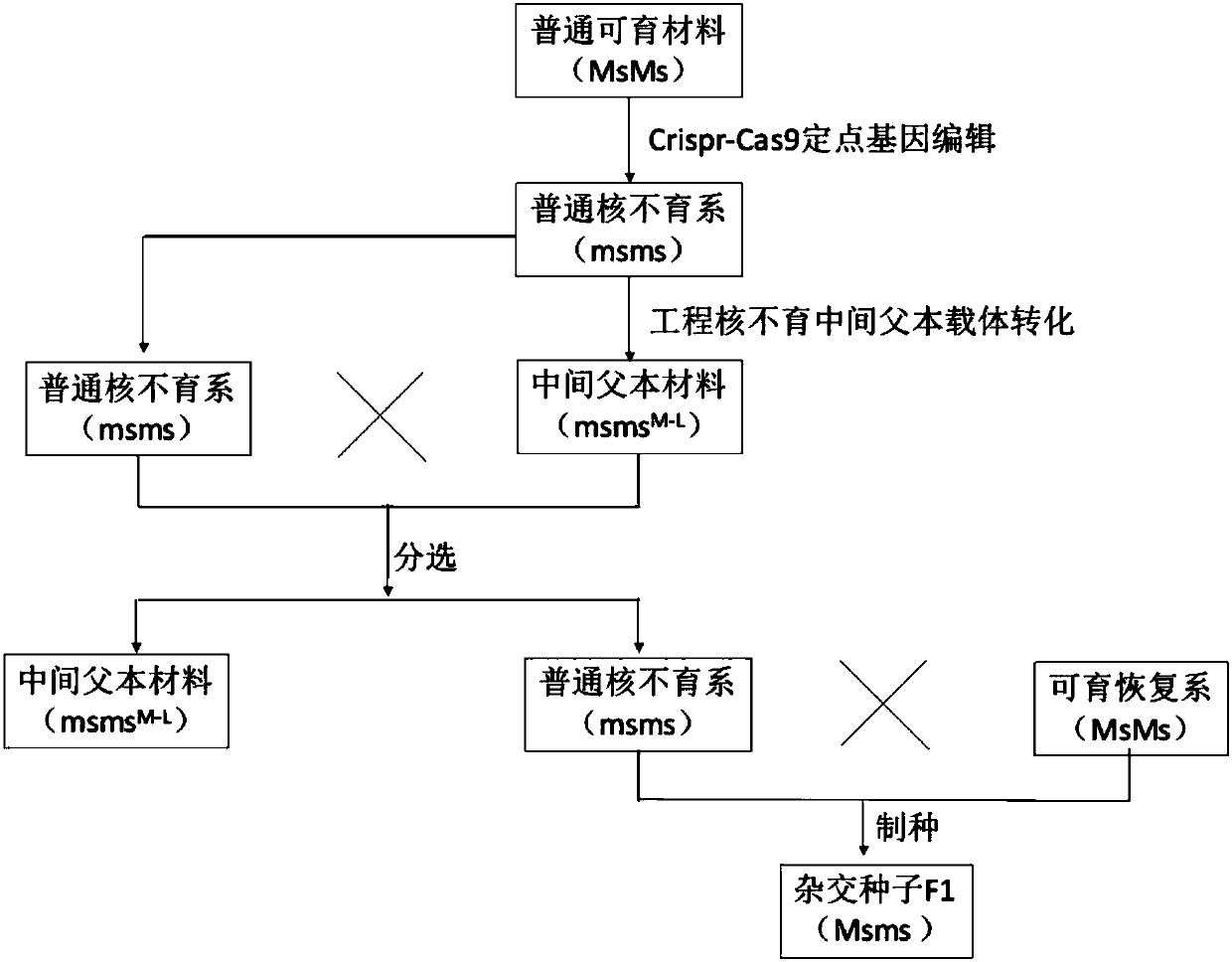

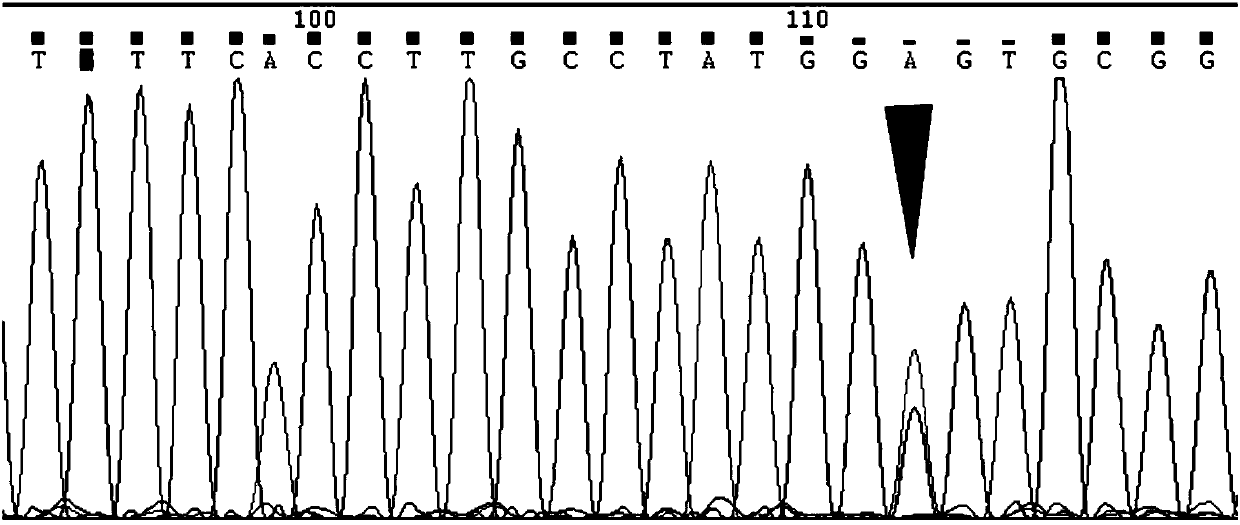

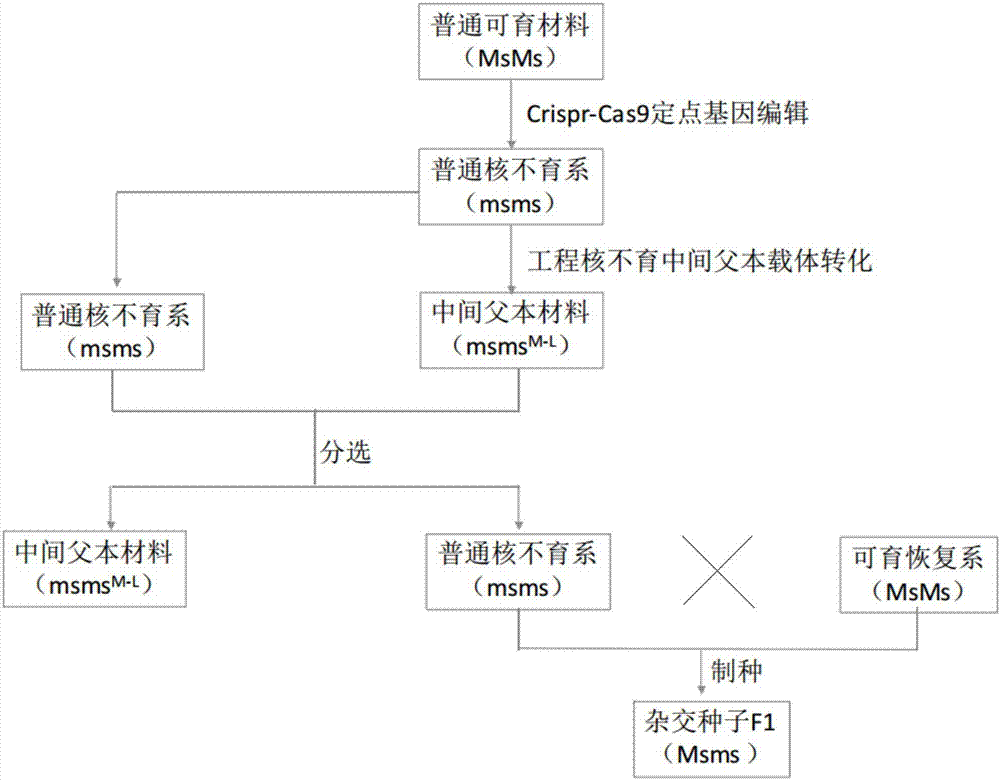

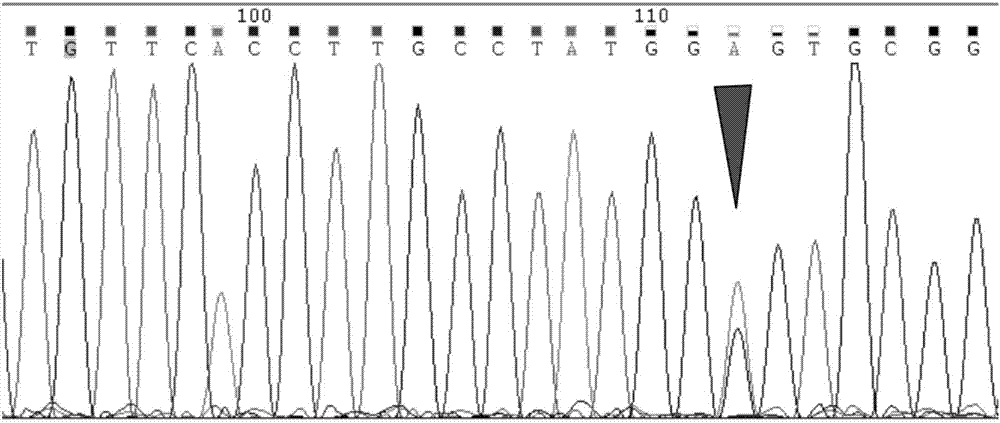

Creation method of paddy rice common nuclear sterile line and application

ActiveCN107667853AAchieve reproductionSimplify the breeding processHydrolasesGenetic engineeringBiotechnologyAnimal science

The invention discloses a creation method of a paddy rice common nuclear sterile line and application. The creation method is characterized a common fertile breeding material is used to create the sterile line, the sterile line is hybridized with an intermediate male parent material, hybrid seeds are sorted according to sorting gene expression characters to obtain a large number of sterile-line seeds which do not contain transgenic components, and the reproduction of the common nuclear sterile line is achieved. The common nuclear sterile line and a restoring line are used to produce the hybridseeds, the breeding procedure is simple, a large amount of backcross transformation time can be saved, the sterile characters of the common nuclear sterile line are fast imported into the fertile material, and the breeding cycle is shortened greatly.

Owner:HUNAN HYBRID RICE RES CENT

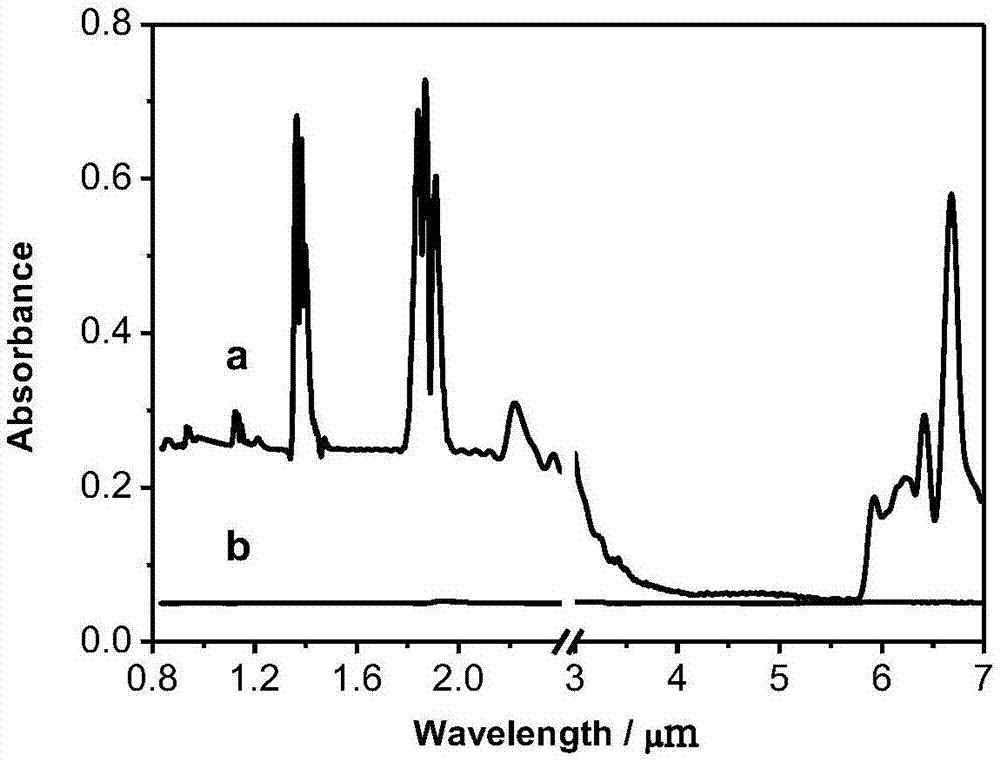

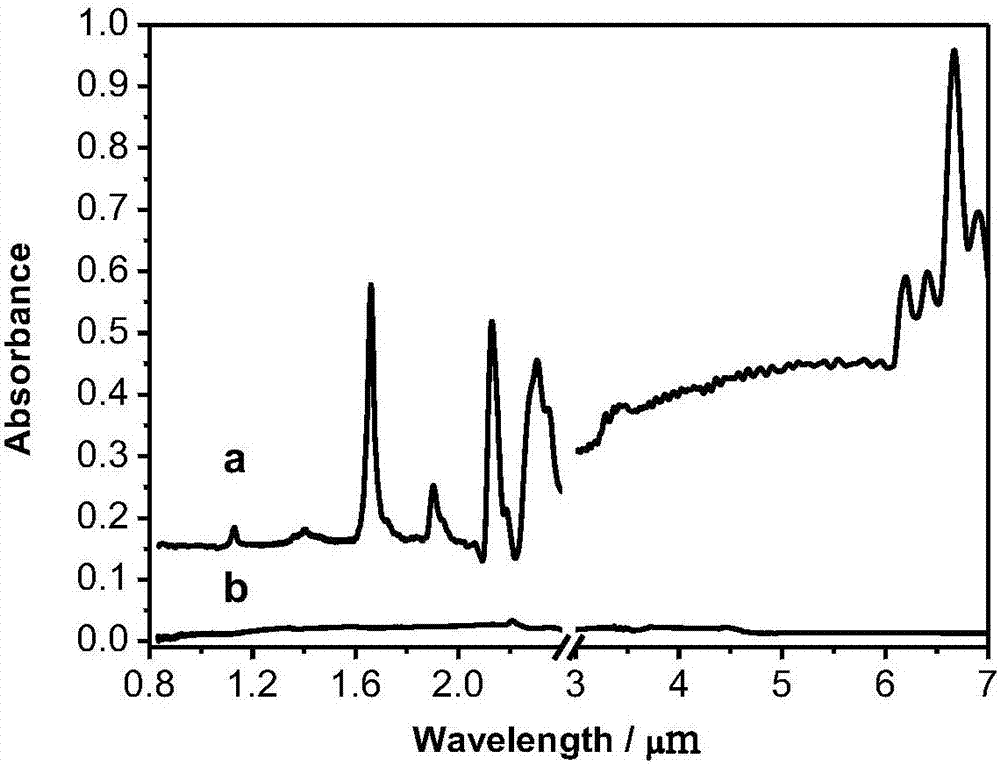

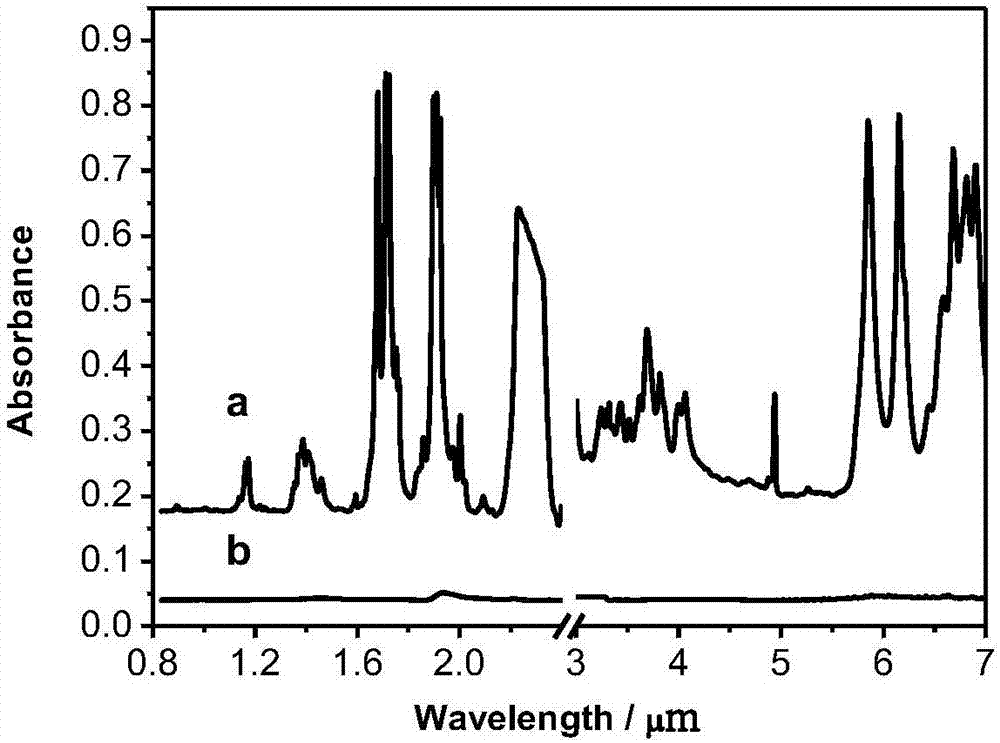

Method for adopting ITO nano-material as surface enhanced substrate of infrared spectrum combined frequency area

InactiveCN107101967ABroadening the Way of Enhanced Infrared TestingIncrease energy matching rangeMaterial nanotechnologyAnalysis by material excitationIndium tin oxideWavelength

The invention relates to a method for adopting an ITO nano-material as a surface enhanced substrate of an infrared spectrum combined frequency area, belonging to the field of nano-techniques and new materials and particularly relates to an innovation method for surface enhanced near infrared (SENIR) detection and surface enhanced infrared absorption spectrum (SEIRAS) detection on a probe molecule in an infrared spectrum combined frequency area (with a length range of 0.7-7.7 microns) by taking a semiconductor nano-material or membrane indium tin oxide (ITO) as a substrate. The method comprises the three steps of synthesizing surface plasmon resonance nano-material ITO, carrying out surface modification preparation on the probe molecule and carrying out SENIR and SEIRAS detection on the probe molecule by taking the ITO nano-particles, films or sol materials as novel SENIR and SEIRAS substrates. The enhanced substrate is used for detecting that SENIR and SEIRAS signals adsorbed to the surface of the ITO nano-material are obviously stronger than infrared signals in the combined frequency area of a probe molecule body. By virtue of the method, the selection range of the substrate material is broadened for the research of an SEIRAS effect; the method is of brand-new extension of an infrared spectrum detection function.

Owner:JILIN UNIV

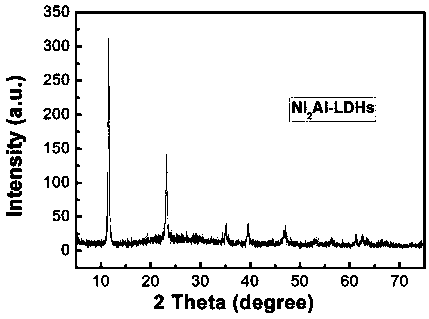

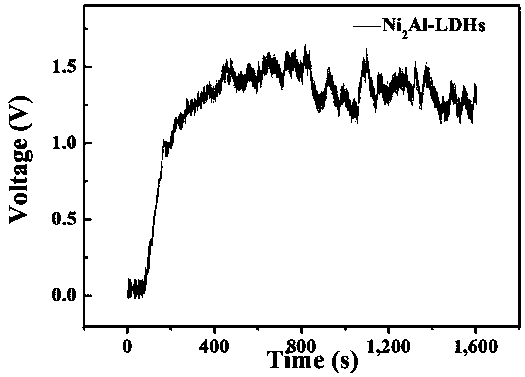

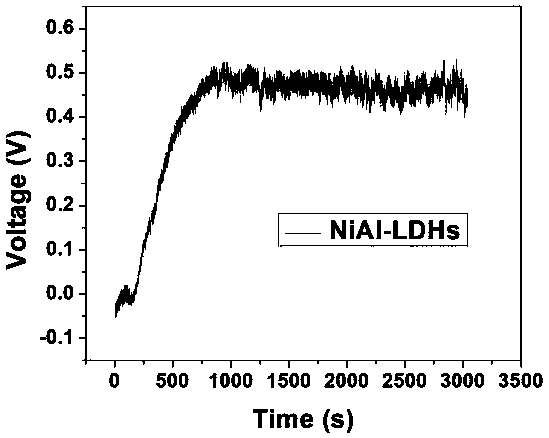

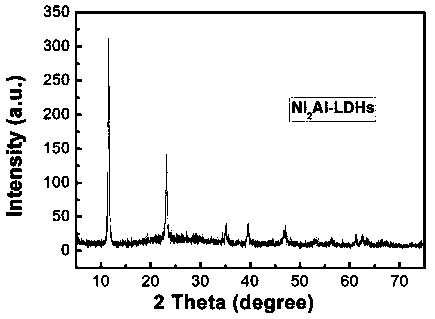

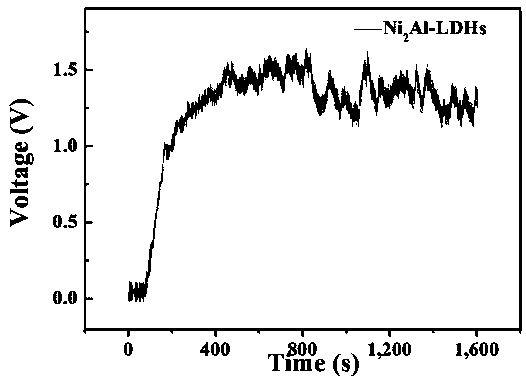

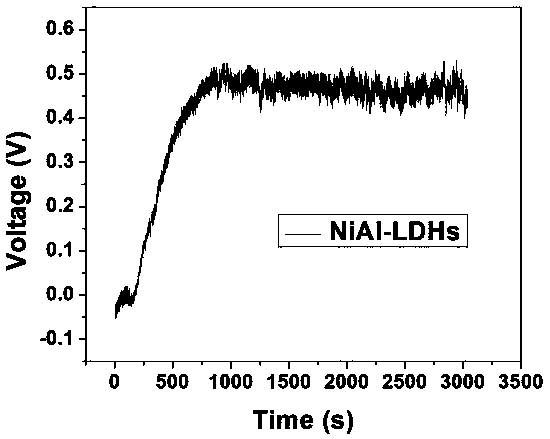

LDHs (Layered Double Hydroxides) based water evaporation generator and preparation method thereof

ActiveCN108285177AEasy to manufactureExtended range of materialsIron compoundsHydrotalciteEvaporationRoom temperature

The invention discloses an LDHs (Layered Double Hydroxides) based water evaporation generator, the LDHs based water evaporation generator is provided with a substrate with a tab, a coating layer is arranged on the substrate, and the coating is LDHs. A preparation method is conducted according to the following steps: preparing an LDHs solid powder; evenly dispersing the LDHs solid powder into a liquid to form an LDHs liquid; coating the LDHs liquid on the substrate with the tab at the room temperature; drying, and enabling the LDHs liquid to form a film evenly. The LDHs based water evaporationgenerator has the advantages that the raw material is convenient to prepare and can be coated at the room temperature, the range of the material for preparing the substrate is expanded, both the hardsubstrate (like a quartz glass sheet) and the flexible substrate (like a plastic sheet, a thin film or a fabric) can be used, and a foundation is laid for the creation of a self-driven wearable device.

Owner:DONGGUAN UNIV OF TECH

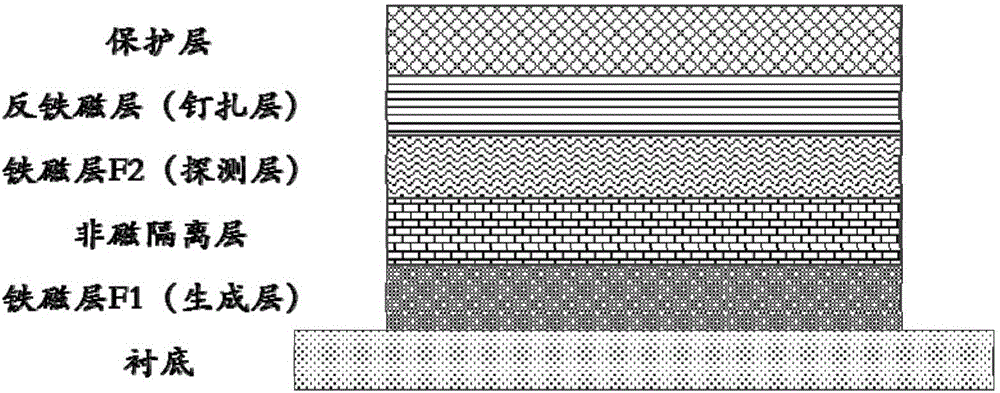

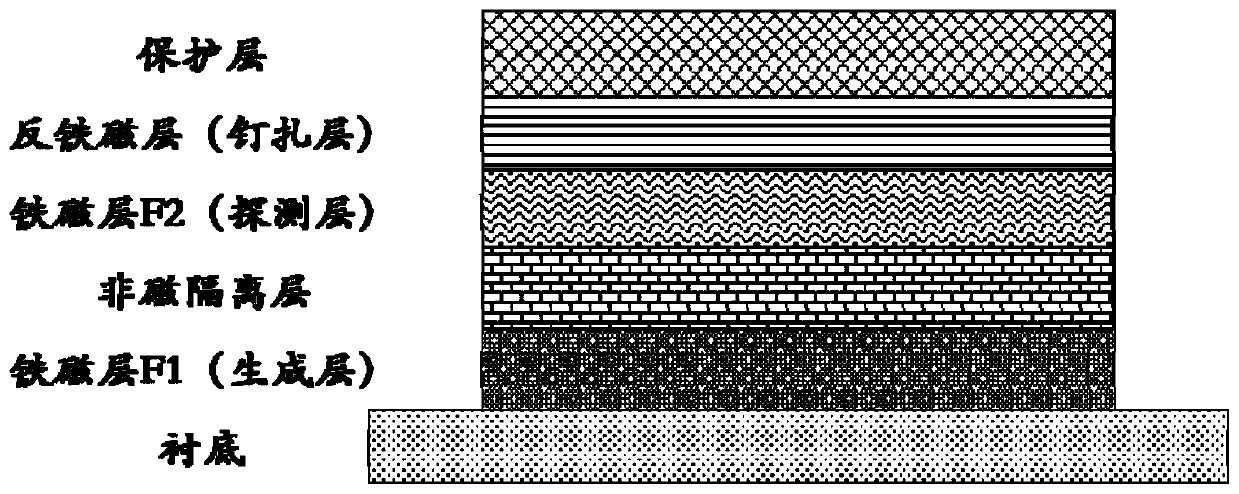

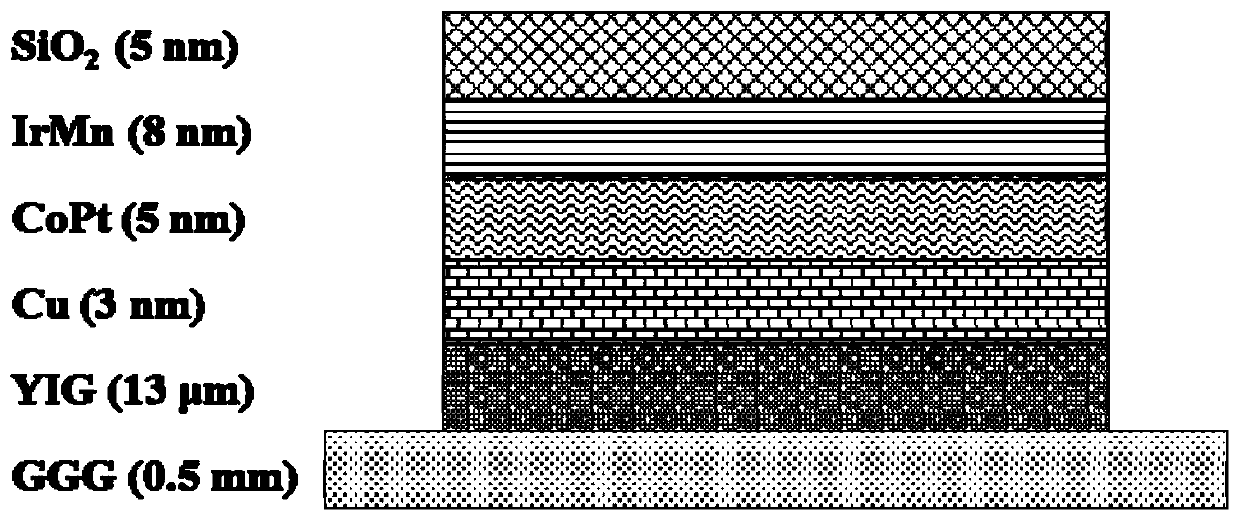

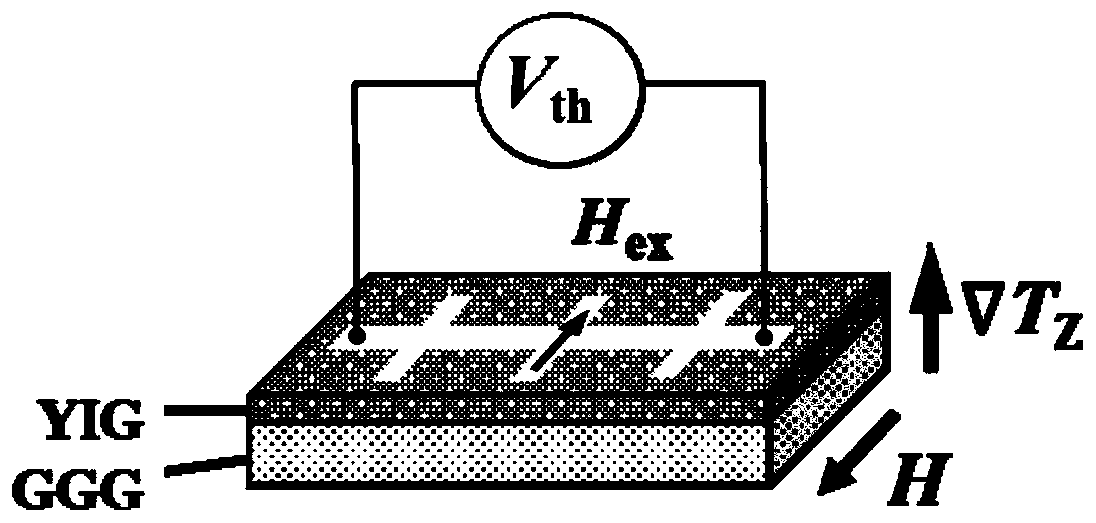

Multilayer film heterostructure and its preparation method and application

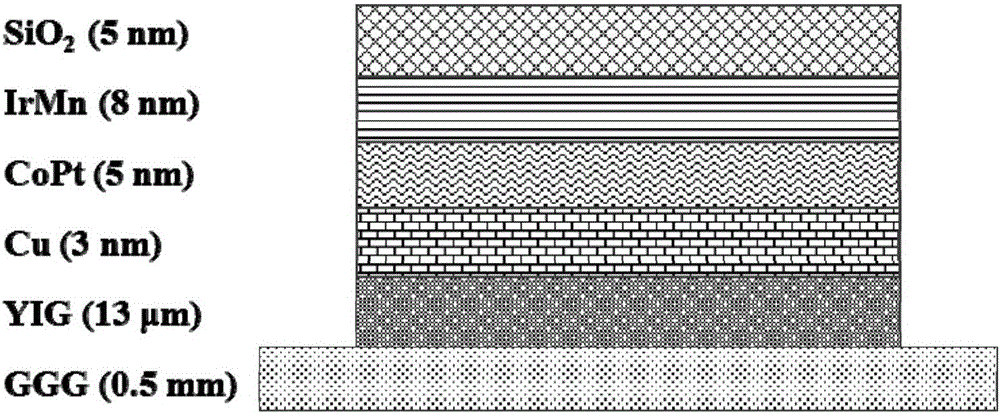

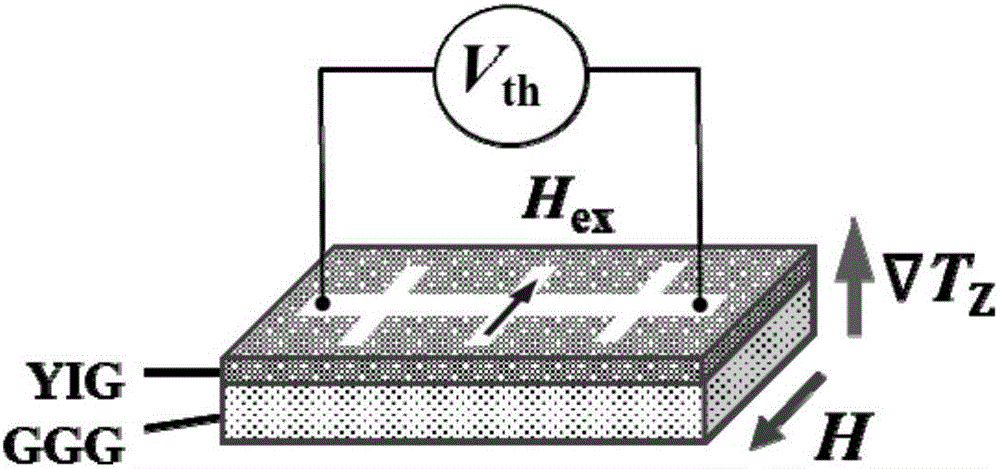

ActiveCN106784299AExtended range of materialsIncrease the number ofGalvano-magnetic devicesThermoelectric device with peltier/seeback effectPhysicsSpin Hall effect

The invention provides a multilayer film heterostructure and its preparation method and application; the multilayer film heterostructure can eliminate disturbances from other thermomagnetic effects and isolate ISHE (inverse spin Hall effect), ANE (anomalous Hall effect) and ARL (anomalous Righi-Leduc effect) in a spin current detection layer clearly and effectively, thereby decreasing the reflection of spin current at an interface, and measuring longitudinal spin Seebeck effect at room temperature; the coercive force of a spin current detection layer is not limited, and the material range suitable for practical application is widened.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

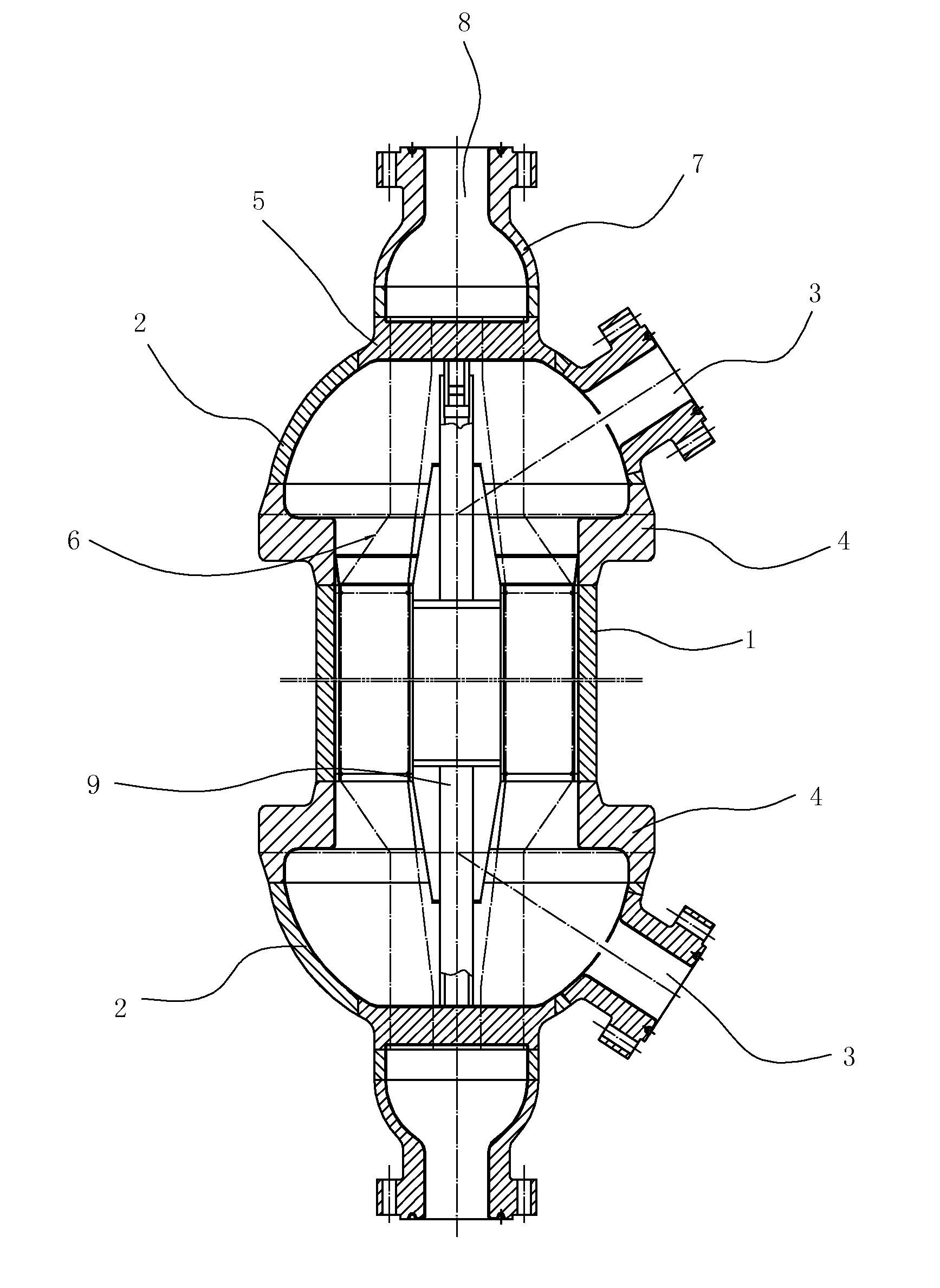

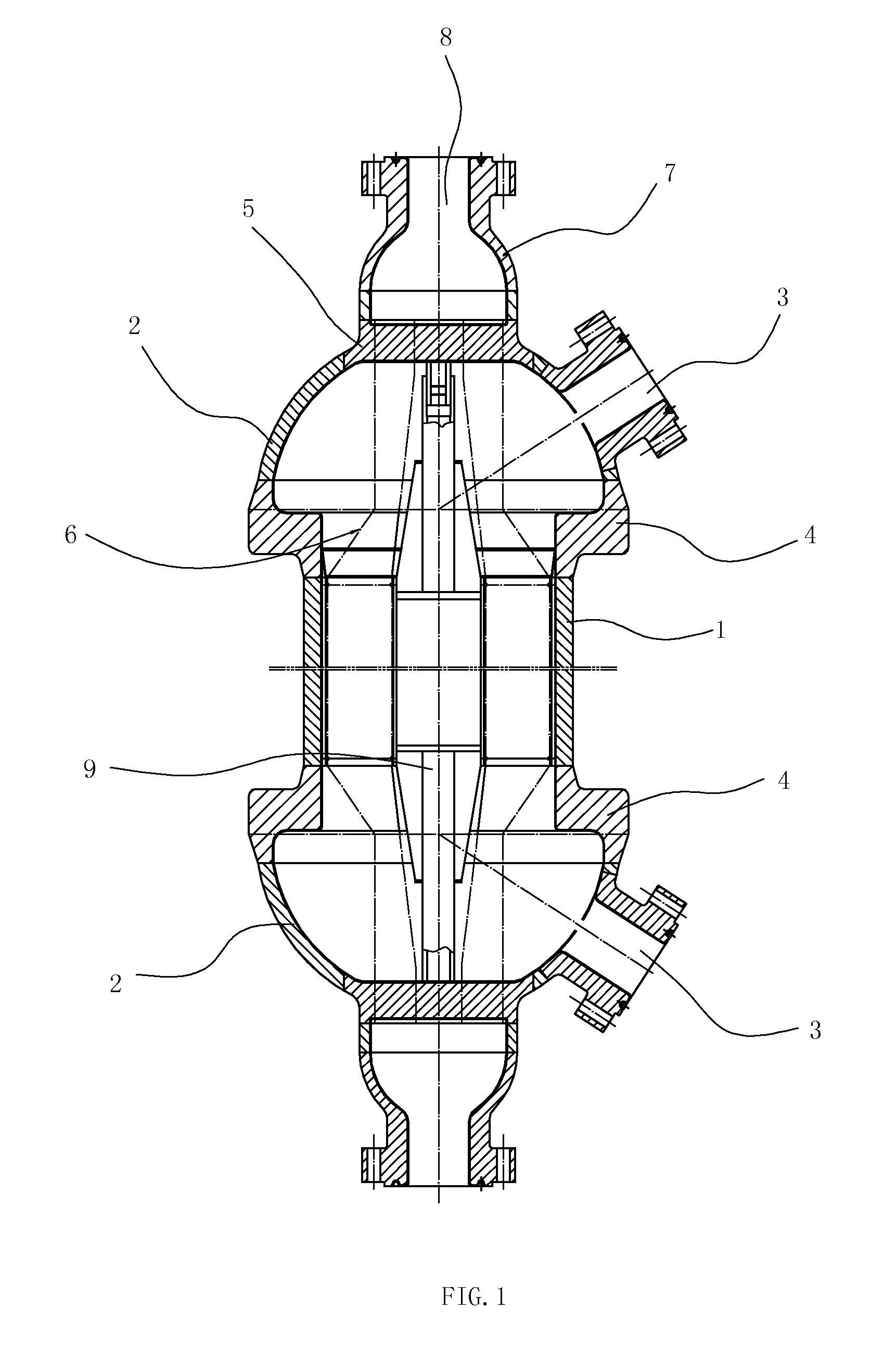

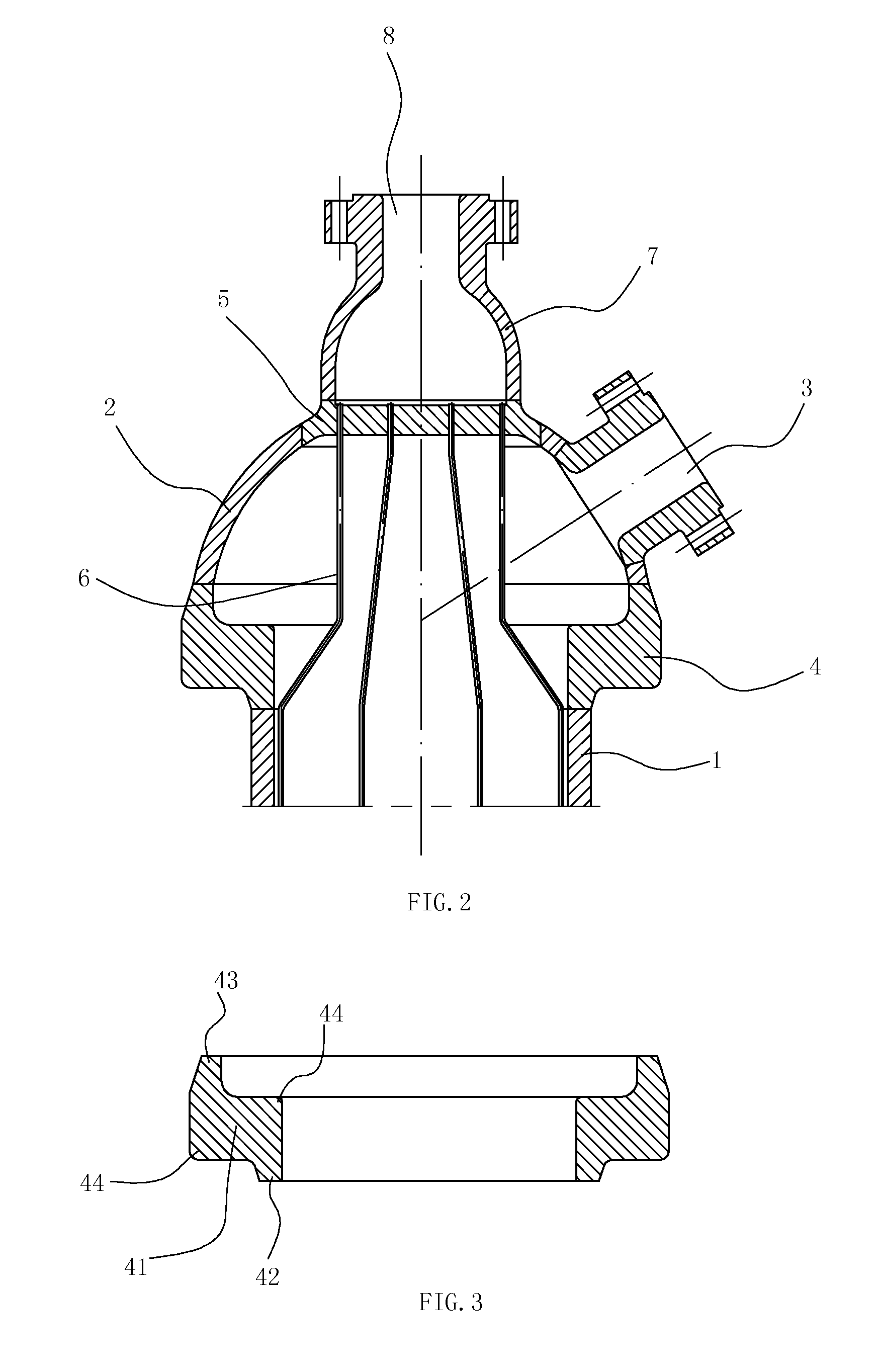

Heat Exchanger

ActiveUS20150198373A1Easy to operateDead area is avoidedHeat exchanger casingsStationary tubular conduit assembliesWorking environmentEngineering

A heat exchange, which includes a casing having a cylinder; two connectors respectively attached to one end of the cylinder through the small opening; two convex heads respectively connected through the opening end to the large opening of a connector; a core disposed inside the casing; and two heat transfer medium passages. In this way, the space at the ends of the casing of the heat exchanger may be enlarged, thereby providing a space large enough to accommodate the construction personal and better working environment for two-side welding and future maintenance and wider selection range of material of the casing of the heat exchanger; a buffer area is provided for the flow of the heat transfer medium, and the auxiliary like baffles may be mounted inside the convex heads as required to further improve the heat exchange efficiency and reduce the cost.

Owner:ZHENHAI PETROCHEM JIANAN ENG

Creation method and application of rice ordinary nuclear sterile line

InactiveCN107245495AAchieve reproductionSimplify the breeding processHydrolasesVector-based foreign material introductionRelationship - FatherAgricultural science

The invention discloses a creation method and application of a rice ordinary nuclear sterile line. The creation method disclosed by the invention has the benefits that the sterile line is created by applying an ordinary fertile breeding material and is then hybridized with a middle father material; after a seed mixture is sorted through sorting gene expression traits, a large amount of sterile line seeds excluding transgenic ingredients is obtained, so that the reproduction of the ordinary nuclear sterile line is realized. The ordinary nuclear sterile line and a restoring line are utilized for seed production to obtain hybridized seeds; the breeding procedure is simple, so that a lot of backcross breeding time can be saved; the sterile traits of the ordinary nuclear sterile line are rapidly guided into a fertile material, so that the breeding period is greatly shortened.

Owner:HUNAN HYBRID RICE RES CENT

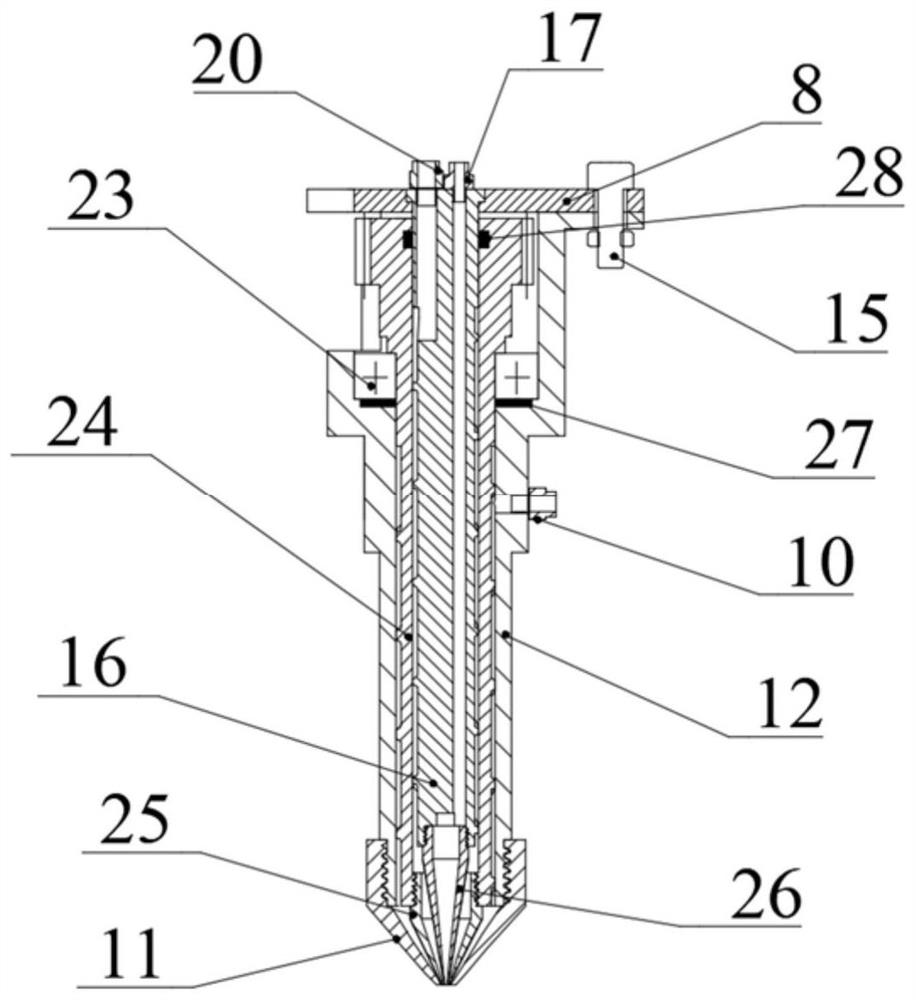

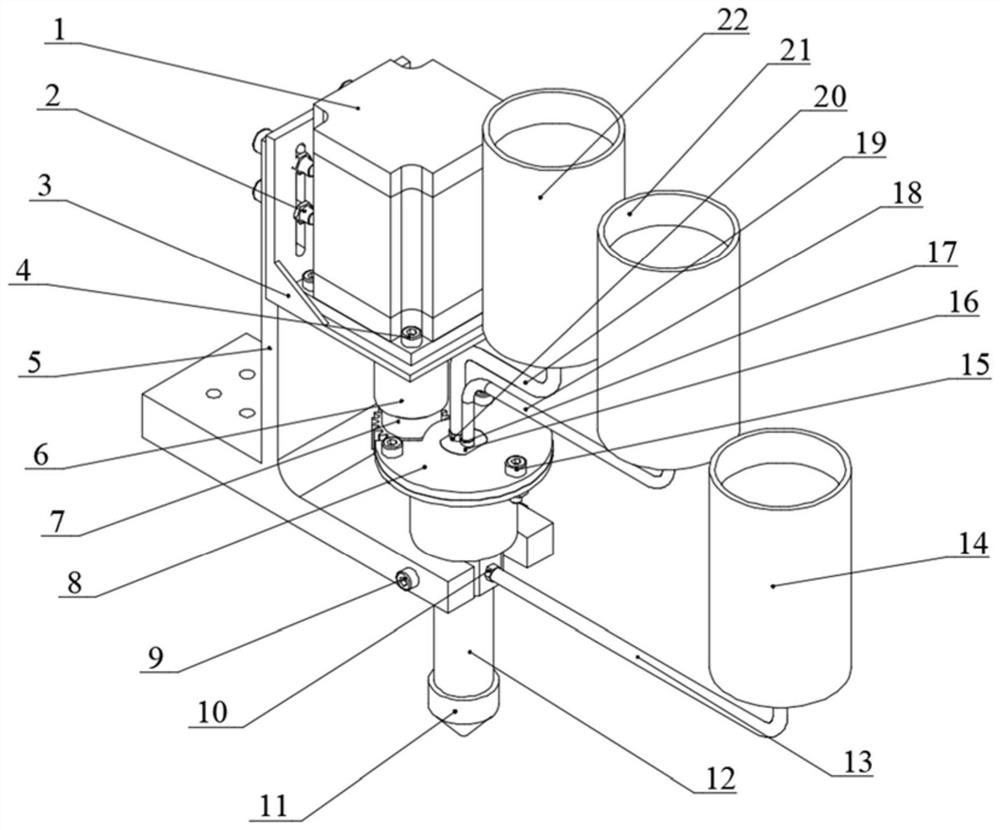

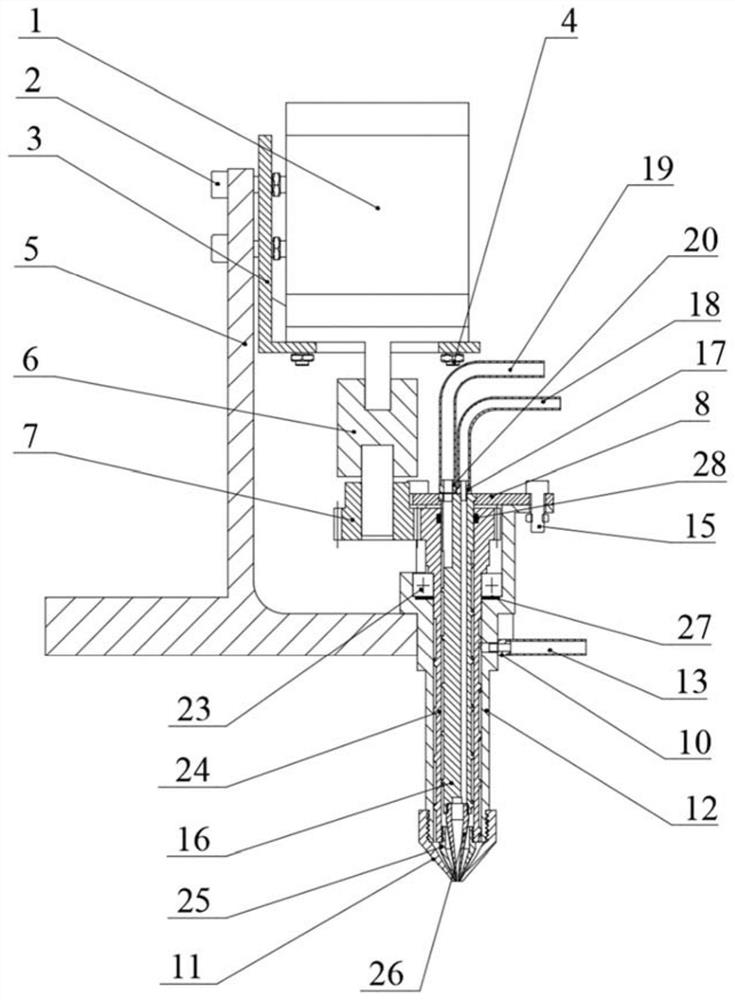

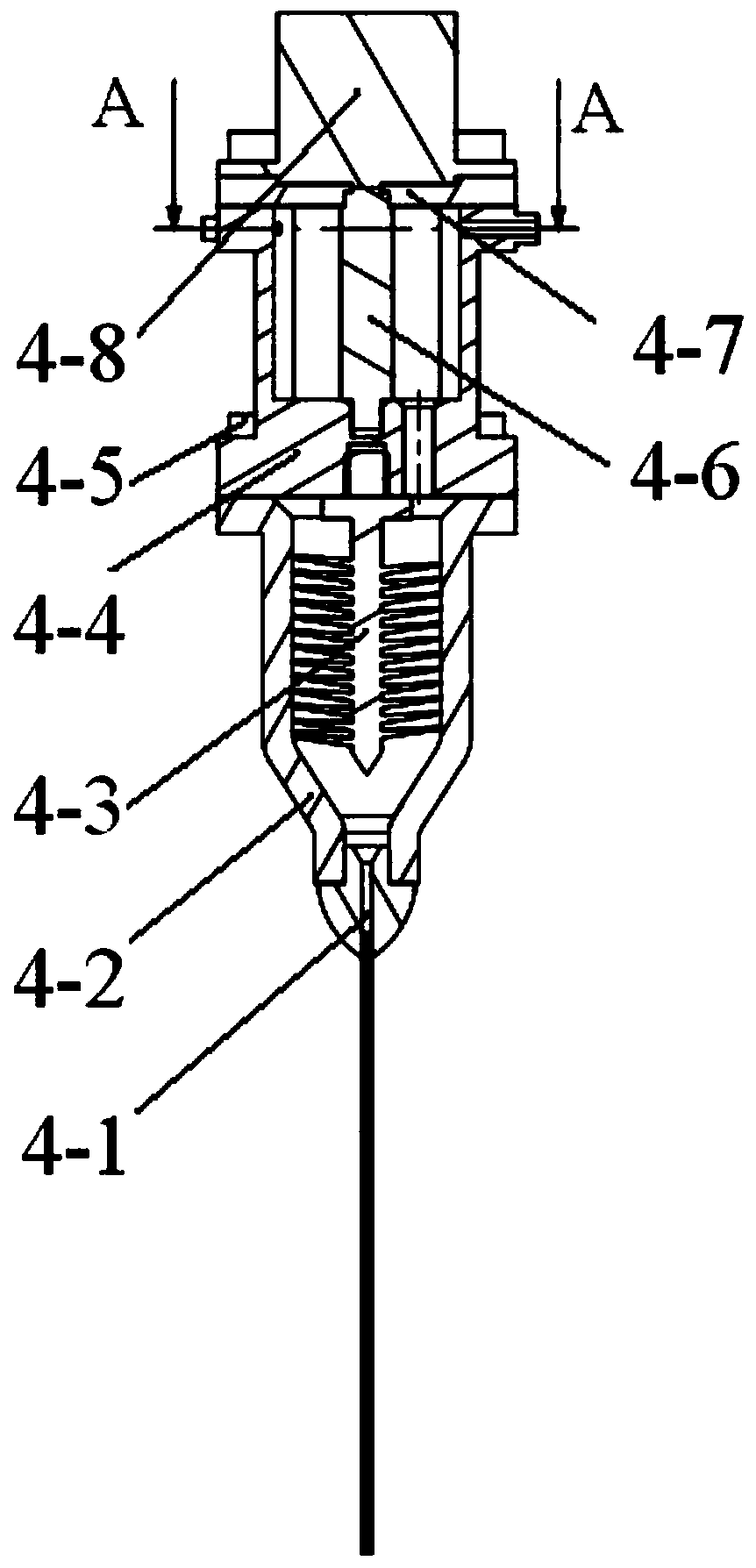

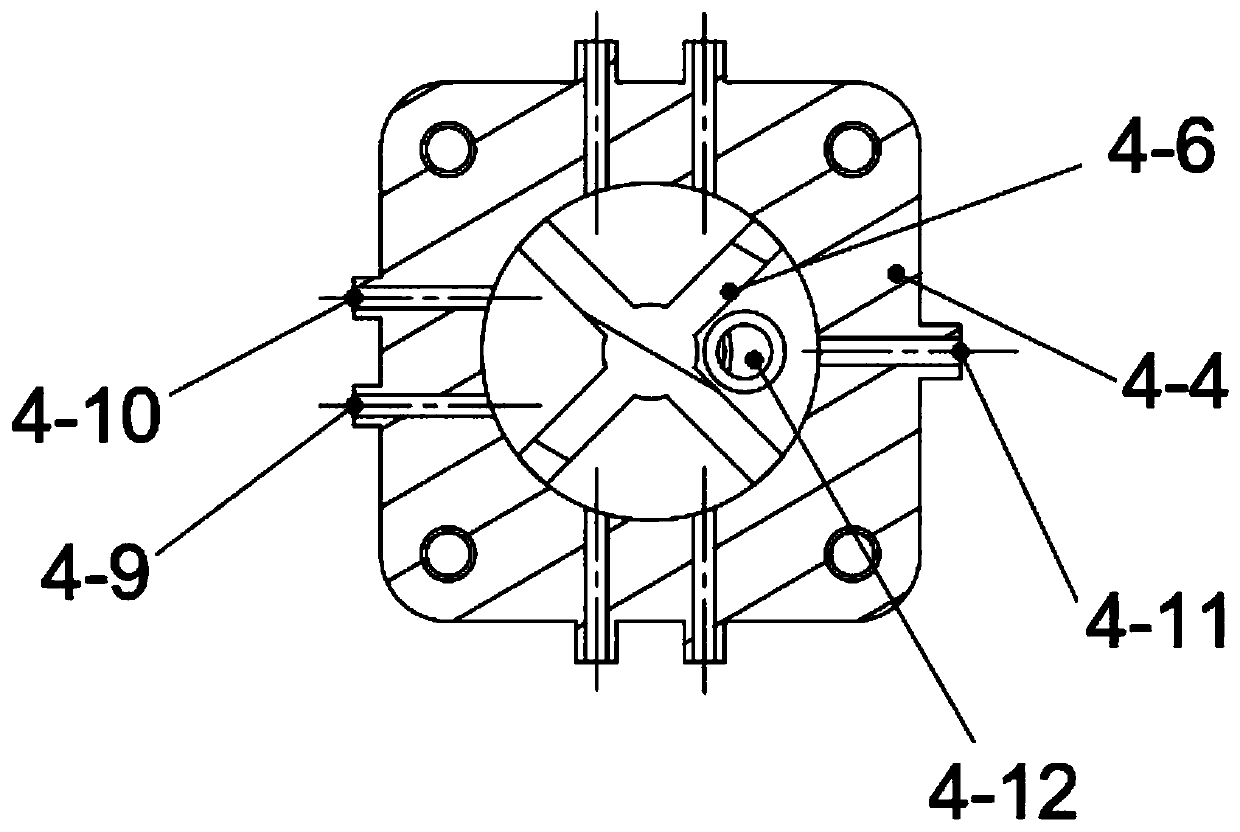

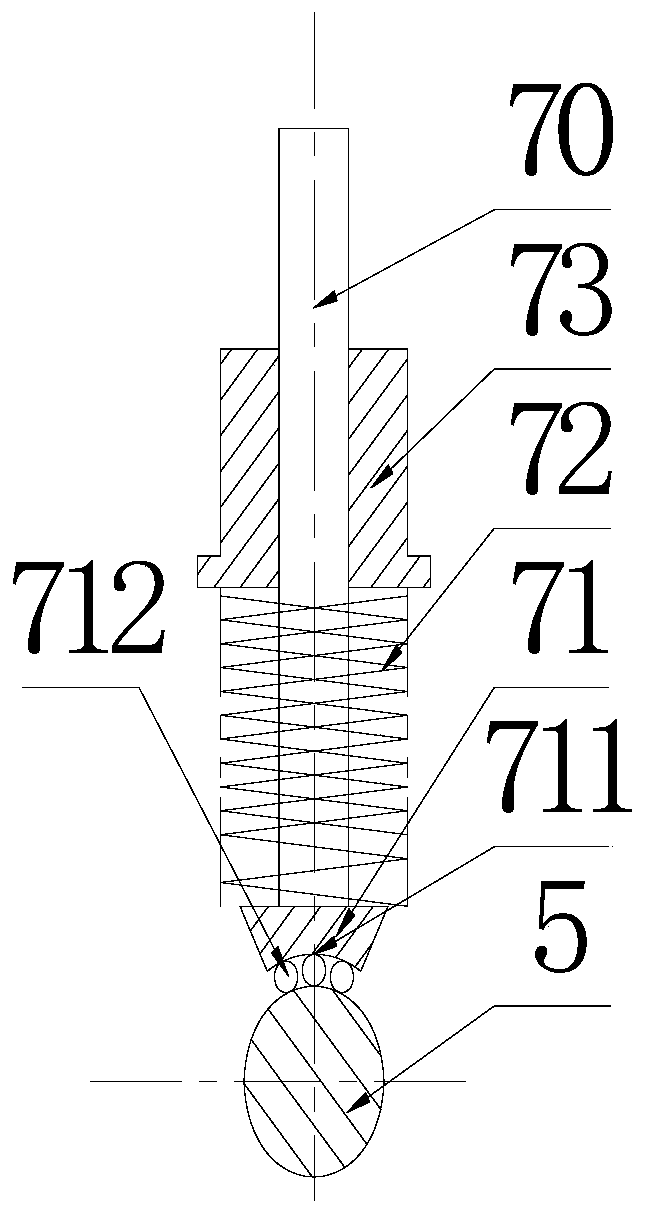

3D printing device and method for high-viscosity resin multiple concentric structure

PendingCN113352601AExtended range of materialsCompact structure3D object support structuresApplying layer meansPrint-throughEngineering

The invention provides a 3D printing device and method for a high-viscosity resin multiple concentric structure. The 3D printing device comprises a motor, wherein a transmission gear is arranged on the motor; an outer extrusion screw is arranged in an outer barrel shell; a gear engaged with the transmission gear is arranged at the top end of the outer extrusion screw; a first closed space is formed by a cavity between the outer barrel shell and the outer extrusion screw; an outer printing spray head is arranged at the bottom of the first closed space; a second closed space is formed by a cavity between an inner extrusion screw and the outer extrusion screw; a middle printing spray head is arranged at the bottom of the second closed space; a third closed space is formed in the inner extrusion screw; an inner printing spray head is arranged at the bottom of the third closed space; and the three spray heads are concentrically arranged. According to the 3D printing device and method, the outer extrusion screw and the inner extrusion screw are arranged, through the rotation shearing action of the inner screw and the outer screw and inner layer material wrapping, direct-writing extrusion printing of a single structure, a dual concentric structure and a triple concentric structure of a high-viscosity resin material can be achieved, and the range of materials capable of being printed through direct-writing printing is widened.

Owner:XI AN JIAOTONG UNIV

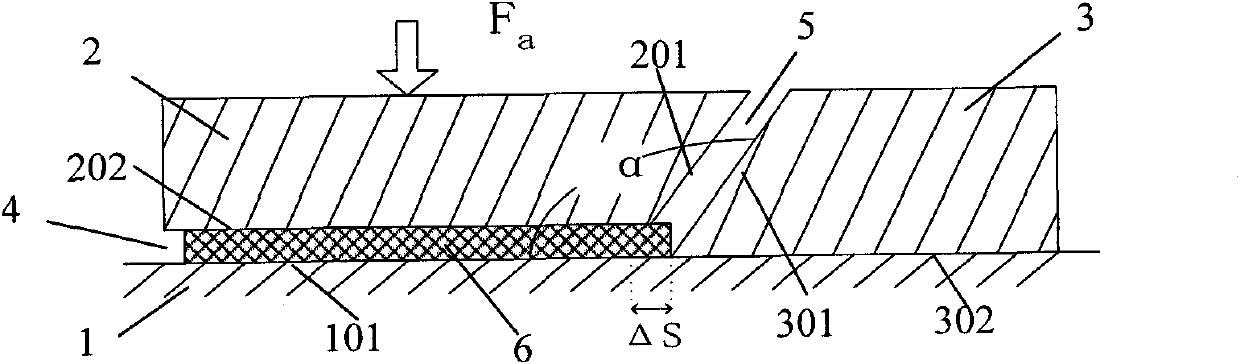

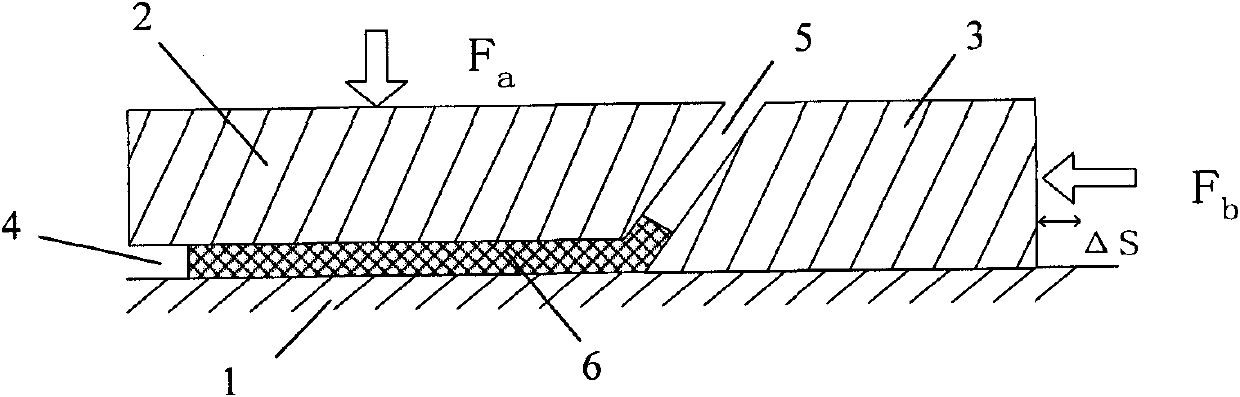

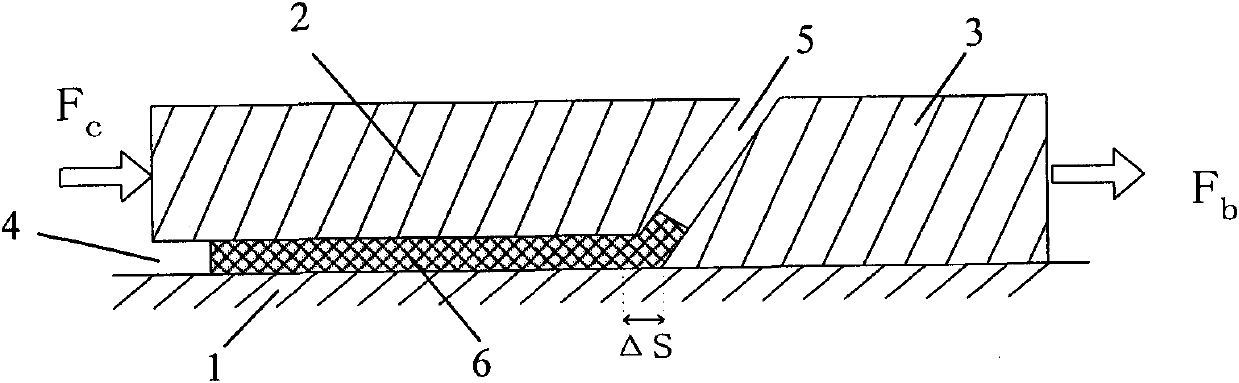

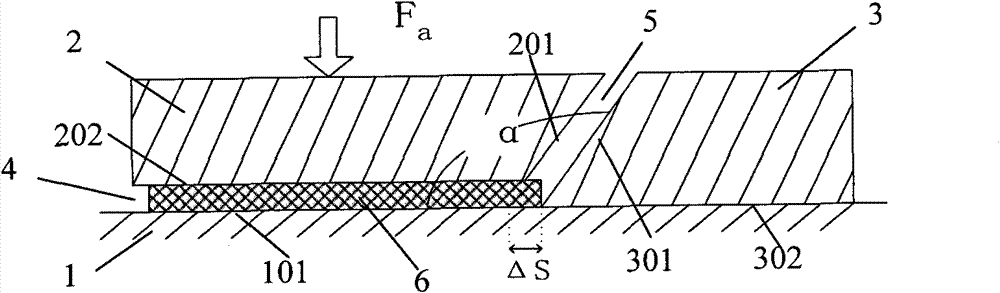

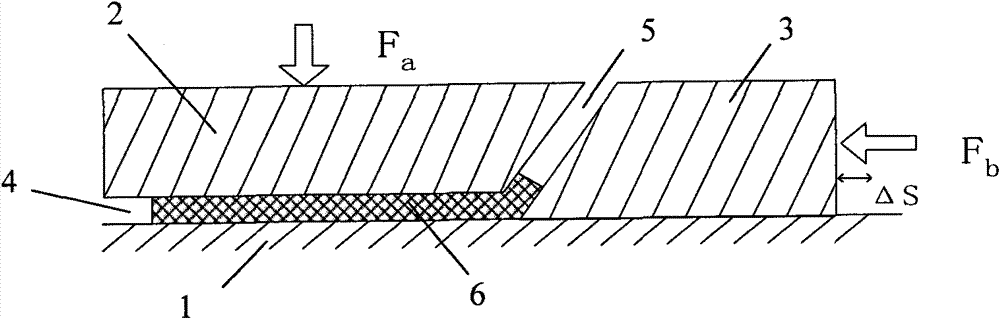

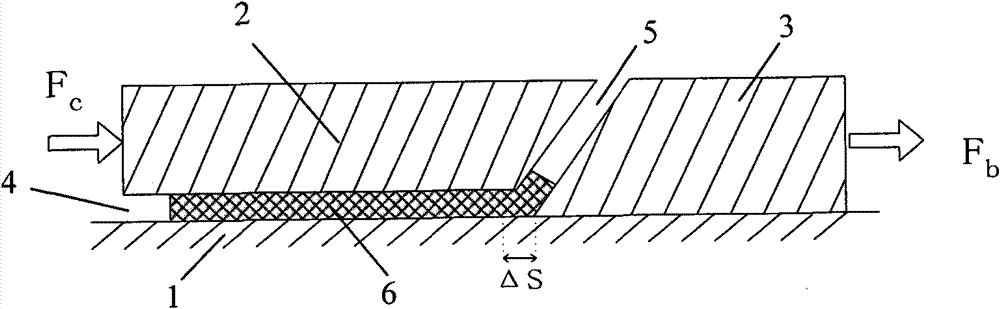

Severe plastic deformation method for grain refinement

ActiveCN102199741AExtended range of materialsContinuous and efficient productionCrystalliteEngineering

A severe plastic deformation method for grain refinement comprises the following steps: 1) a severe plastic deformation channel is formed by employing three modules, wherein a first module is on the bottom and a second module is arranged above the first module to form a first channel, and a third module arranged on the first module and the second module form a second channel; 2) a workpiece to be processed is disposed in the first channel, and a vertical pressure is applied on the second module to compact the workpiece to be processed; 3) a push force parallel to the first channel is applied on the third module to drive the second module to move a step along a direction against the first channel, so that the workpiece is extruded into the second channel by a step; 4) the positive pressure applied on the second module and the third module push force are released to drive the second module and the third module to retreat to initial positions; 5) step 2-4 are repeated to complete extruding. According to the invention, demands of die material and precision by the severe plastic deformation can be lowered, preparative material scope is widened, integrally uniform refinement crystal grains can be obtained, and a workpiece dimension maintains the same after processing.

Owner:BAOSHAN IRON & STEEL CO LTD

Water evaporation power generation device and preparation method based on ldhs

ActiveCN108285177BEasy to manufactureExtended range of materialsIron compoundsHydrotalciteEvaporationRoom temperature

The invention discloses a water evaporation power generation device based on LDHs, which has a base equipped with tabs and a coating on the base, and the coating is LDHs. The preparation method is carried out according to the following steps: preparing LDHs solid powder; uniformly dispersing the LDHs solid powder in the liquid to form an LDHs liquid; coating the LDHs liquid on a substrate equipped with tabs at room temperature; drying to make the LDHs liquid uniformly form membrane. Not only has the advantages of simple raw material preparation and coating at room temperature, but also expands the range of materials for preparing substrates, not only hard substrates (such as quartz glass sheets, etc.), but also flexible substrates (such as plastic sheets, film or fabric, etc.), laying the foundation for the creation of self-driving wearable devices.

Owner:DONGGUAN UNIV OF TECH

Online component-variable photocuring 3D printing device and method

PendingCN113059792ARealize printingExtended range of materialsAdditive manufacturing apparatusAdditive manufacturing with liquidsPhysicsLaser printing

The invention relates to the technical field of 3D printing, in particular to an online component-variable photocuring 3D printing device and method. The device comprises a base, a laser generation module, an injection pump, two or more injectors, a material mixing and feeding mechanism, an X-axis moving module, a scraper, a Y-axis moving module, a printing platform and a Z-axis moving module, wherein the laser generation module, the injection pump, the injectors, the material mixing and feeding mechanism, the X-axis moving module, the scraper, the Y-axis moving module, the printing platform and the Z-axis moving module are mounted on the base. The injection pump drives the injectors to achieve material conveying, discharging ports of the injectors communicate with a material mixing cavity in the material mixing and feeding mechanism through a pipe body, the X-axis moving module drives the material mixing and feeding mechanism to move so that a discharging port of the material mixing and feeding mechanism can move to the position above the printing platform, the Y-axis moving module drives the scraper to move to slick materials on the printing platform, the Z-axis moving module drives the printing platform to move up and down, and a laser printing opening of the laser generation module is formed above the printing platform. By means of the device and method, printing to high-viscosity materials can be achieved, and multiple kinds of materials can be printed according to different proportions.

Owner:JIANGNAN UNIV

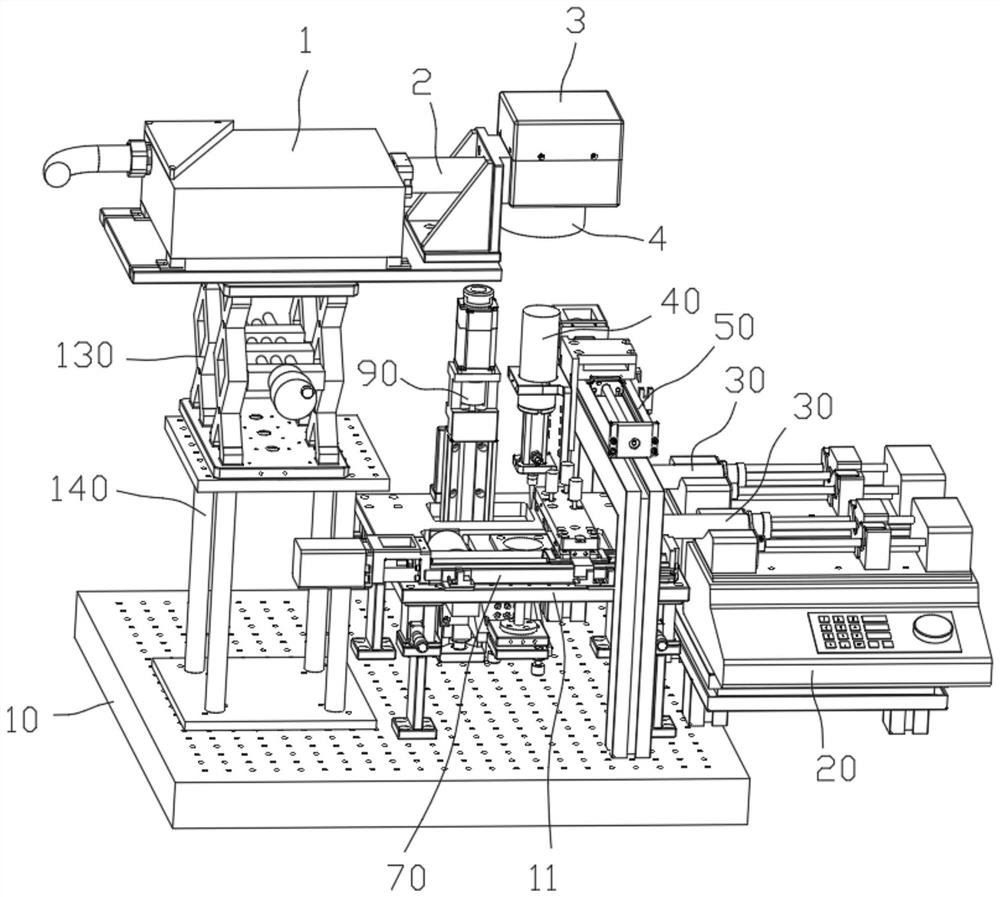

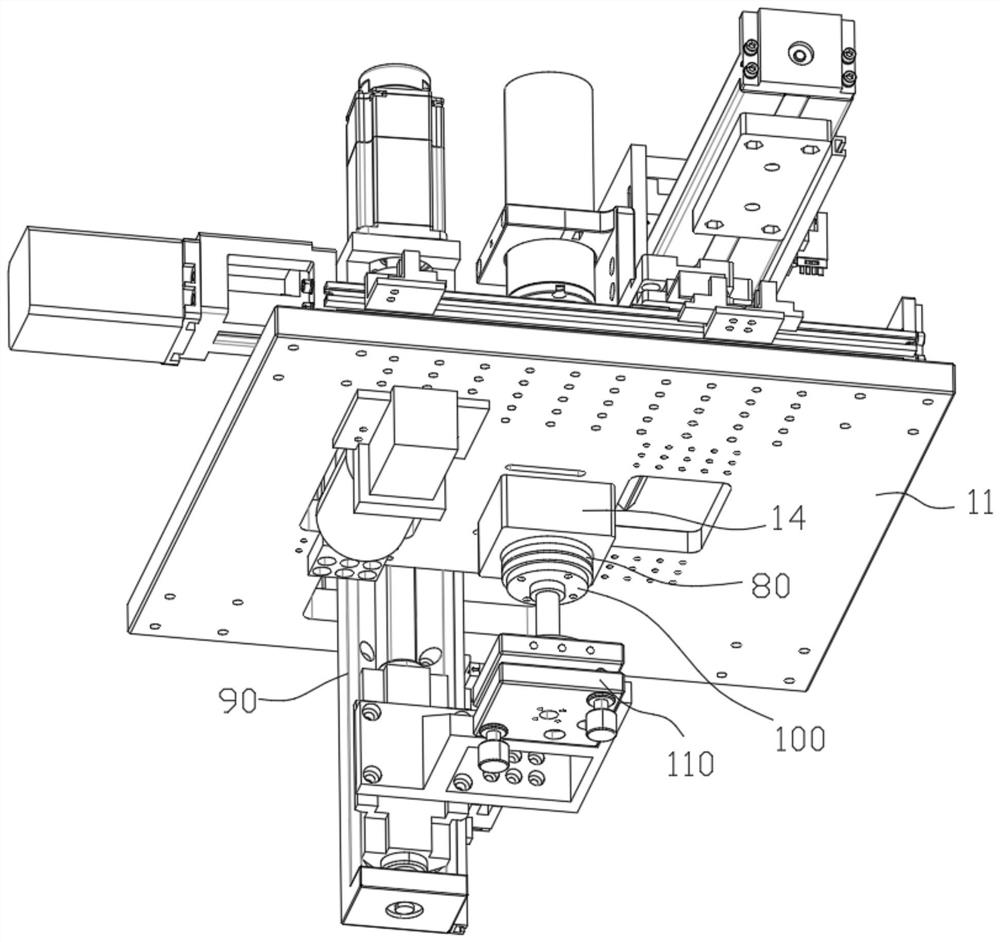

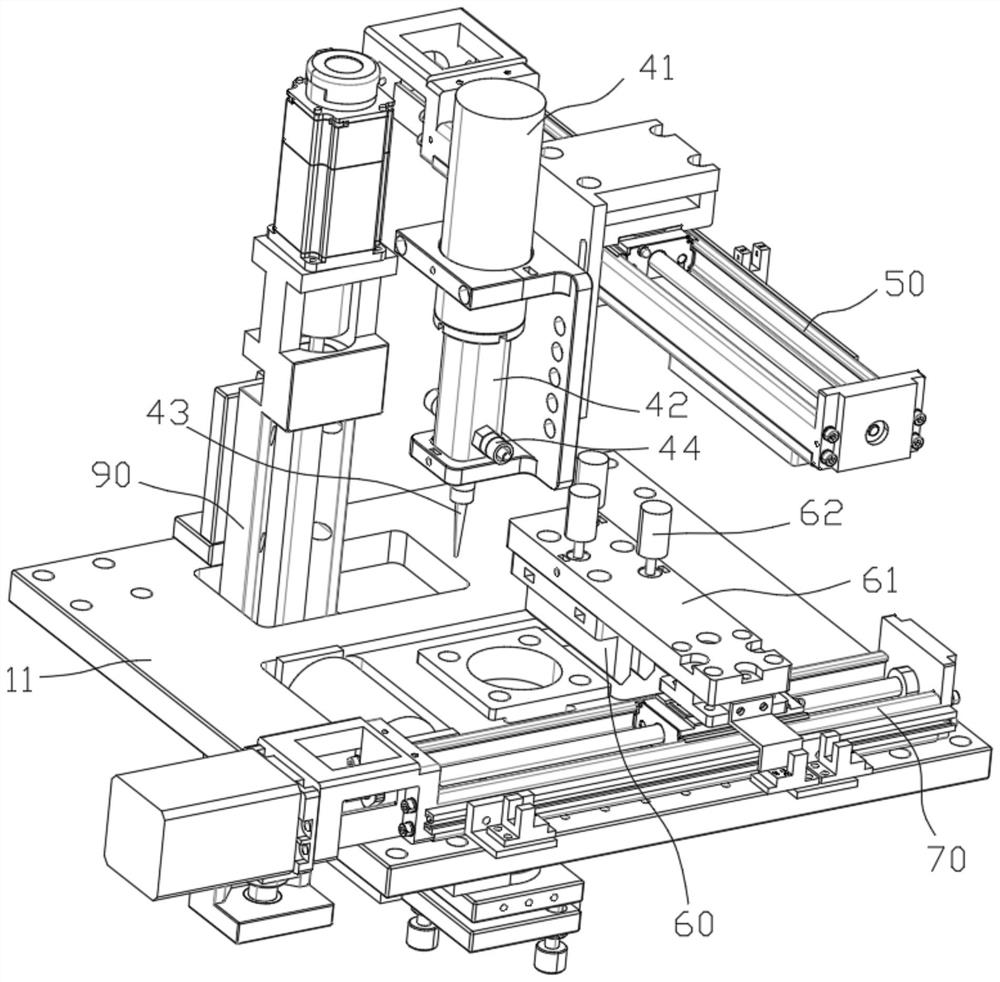

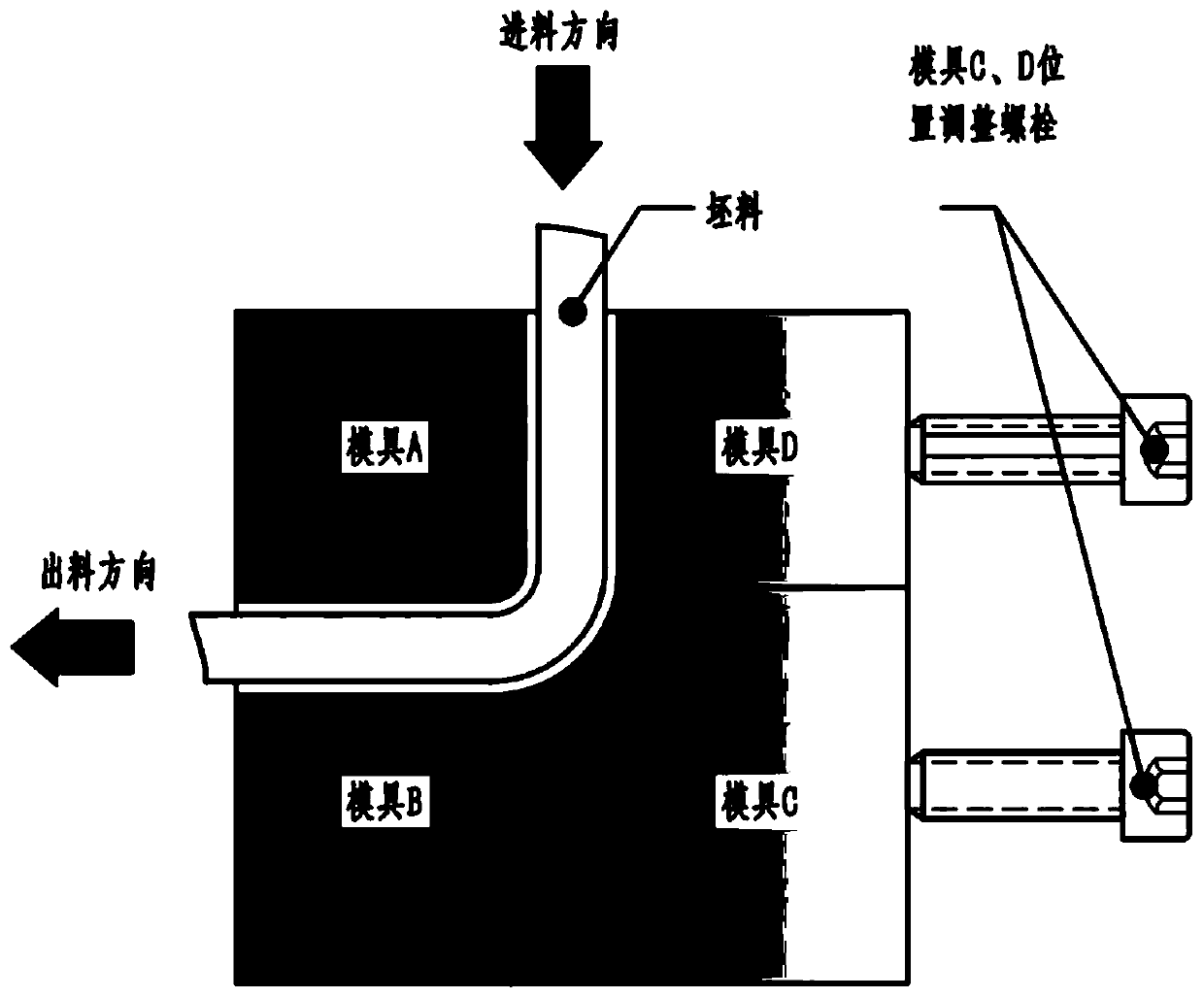

An Equal Channel Angle Drawing Method for Efficient and Continuous Preparation of Ultra-fine-grained Pure Titanium at Room Temperature

ActiveCN107824625BImprove the disadvantage of limited sizeContinuous and efficient productionDrawing diesRoom temperatureUltra fine

The invention provides an equal-channel corner drawing method for efficiently and continuously preparing ultra-fine-grained pure titanium at room temperature. The method is realized through an equal-channel corner drawing mold composed of four modules A, B, C, and D. The steps include: using pure Titanium rods or plates are used as starting materials. After annealing, equal channel corner drawing molds are made according to the cross-sectional shape and size of the starting raw materials; the blank is polished, and its surface and the surface of the four molds pre-formed equal channel corner channels are coated Cover with lubricant; place the blank in an equal-channel corner channel formed by four molds with an angle of 90° or 110°, and then place it on the drawing machine. Control the drawing speed at 2 to 100mm / s to make the blank pass through at a uniform speed. In the equal channel corner channel, after each pass of drawing is completed, remove the head and tail of the drawn piece, rotate the drawn piece clockwise or counterclockwise by an angle θ, and then reposition it in the equal channel corner channel to continue drawing. After 2 to 12 passes of drawing, ultra-fine grained pure titanium material is obtained.

Owner:NORTHEASTERN UNIV LIAONING

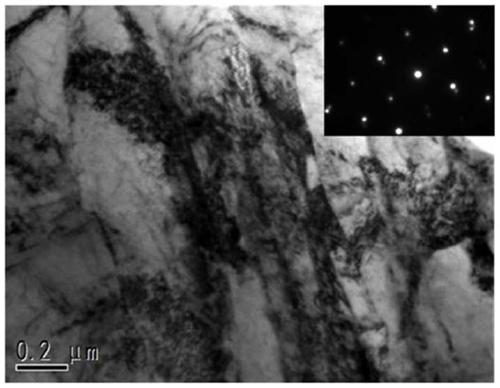

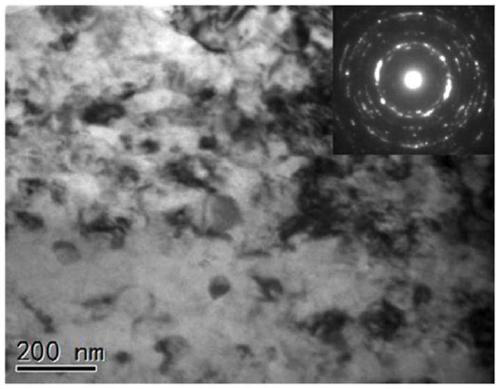

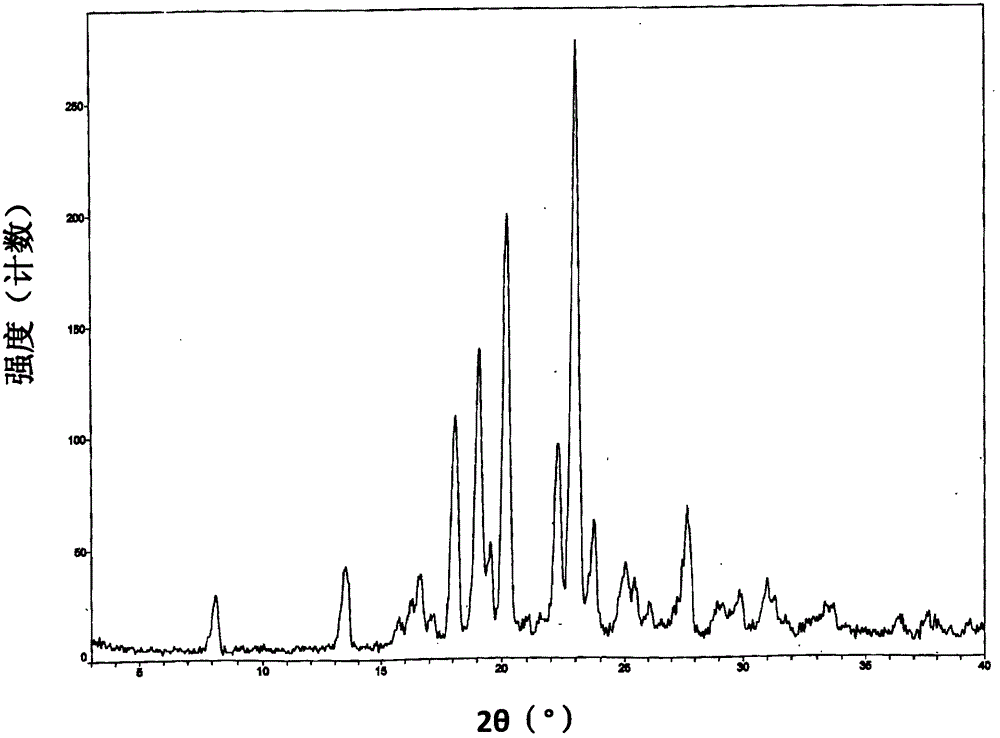

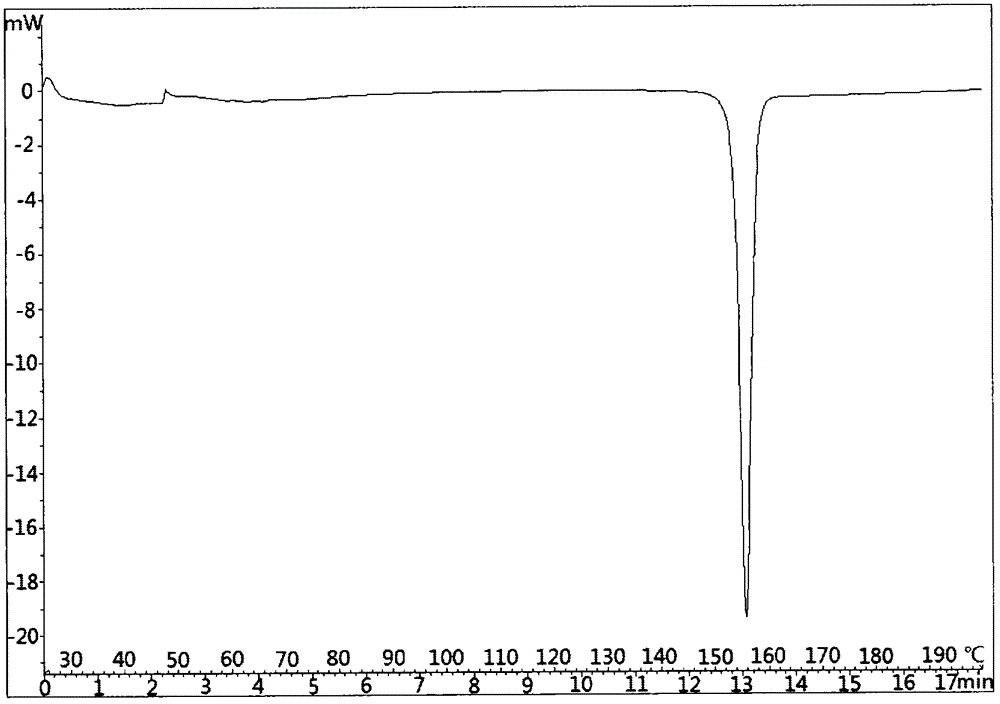

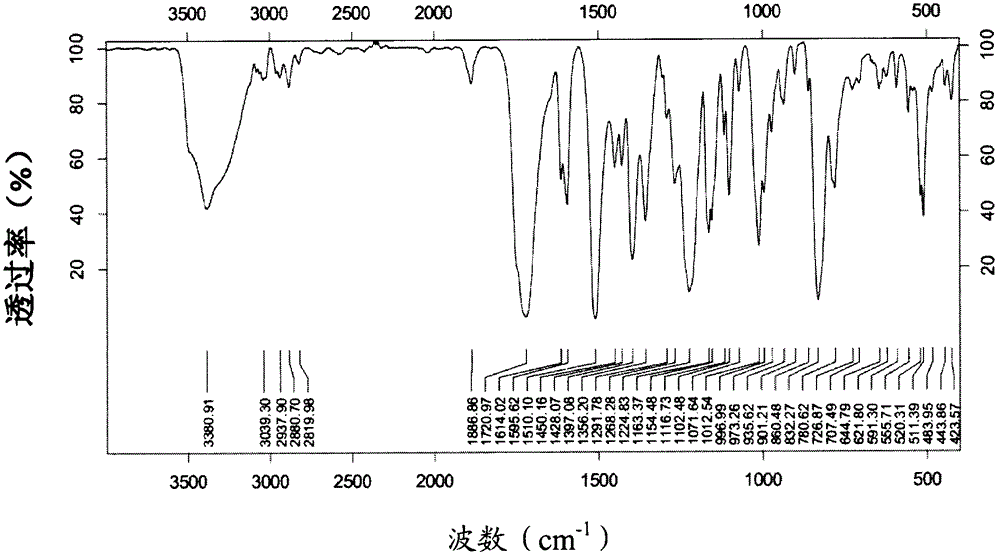

Crystal form of azetidinone compound and preparation method thereof

ActiveCN104603104BGuaranteed stabilityImproved performance characteristicsOrganic active ingredientsMetabolism disorderChemical compoundNitrogen

The present invention provides (3R,4S)-4-(4-hydroxyphenyl)-3-[3-(4-fluorophenyl)-4-hydroxybutyl-2(Z)-ene]-1-( 4-fluorophenyl)-2-azetidinone (formula A) compound crystal form, which can be identified by X-powder diffraction (XRPD) spectrum, differential scanning calorimetry (DSC) spectrum, infrared spectrum, etc. characterization. At the same time, the present invention also provides the preparation method of the crystal form of the compound of formula A, their pharmaceutical composition and application.

Owner:ZHEJIANG HISUN PHARMA CO LTD

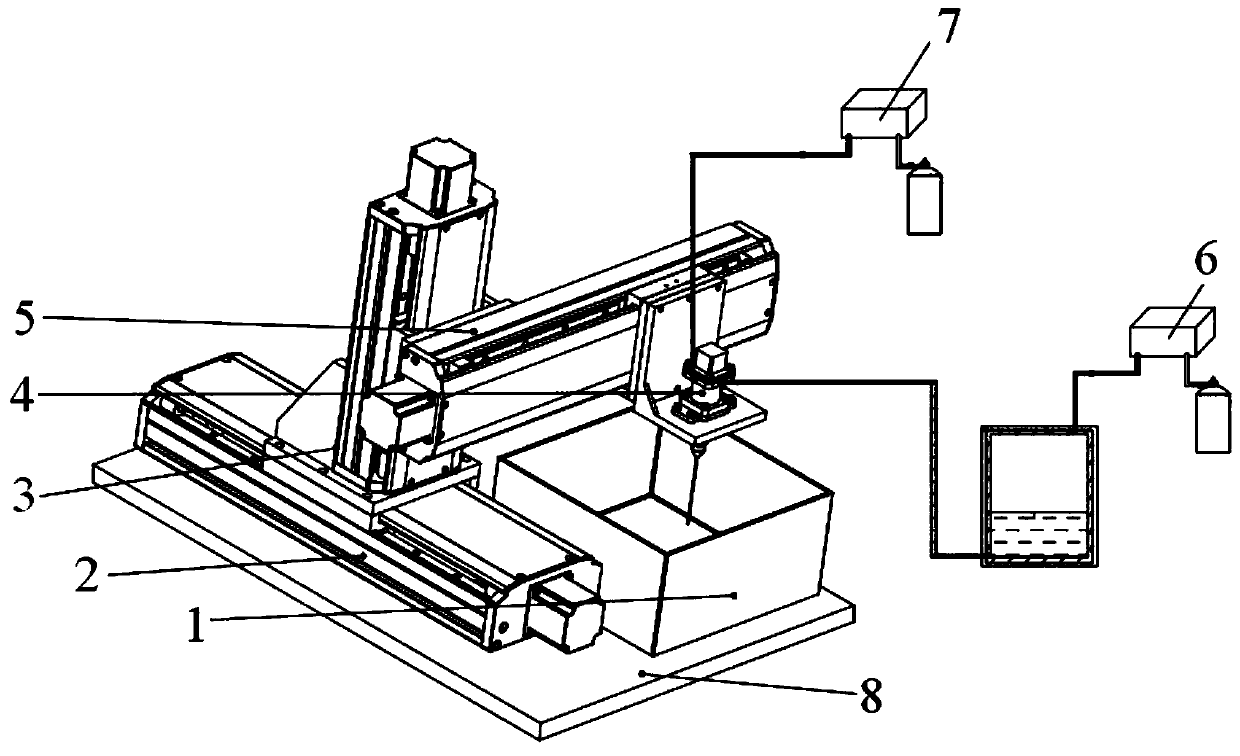

3D printing device and method free of supporting liquid phase mixed materials

PendingCN109822902ANovel structureExtended range of materialsAdditive manufacturing apparatus3D object support structuresEngineeringMixed materials

The invention relates to a 3D printing device and method free of supporting liquid phase mixed materials, and belongs to the technical field of 3D printing. A container is fixed to a base; a Y-axis motion drive is fixed to the base; a Z-axis motion drive is connected to a sliding block of the Y-axis motion drive through a screw; an X-axis motion drive is connected to a sliding block of the Z-axismotion drive through a screw; a printing spray head is connected to a sliding block of the X-axis motion drive through a connecting block and a screw; three feeding openings of the printing spray headare connected to three sets of feed systems through guide pipes correspondingly; and a gas inlet opening is connected to a gas supply system through a guide pipe. The 3D printing device and method have the advantages that the structure is novel; the material range of 3D printing is widened, and the 3D printing device and method can be suitable for flexible materials and bioactive materials; the process of printing supporting materials is omitted; the time of removing a supporting structure and printing raw materials are saved; the process that materials need to be pre-mixed before printing isomitted; the printing time is saved; the feed quantity of the raw materials is precisely controlled; and the raw materials are mixed sufficiently and evenly.

Owner:JILIN UNIV

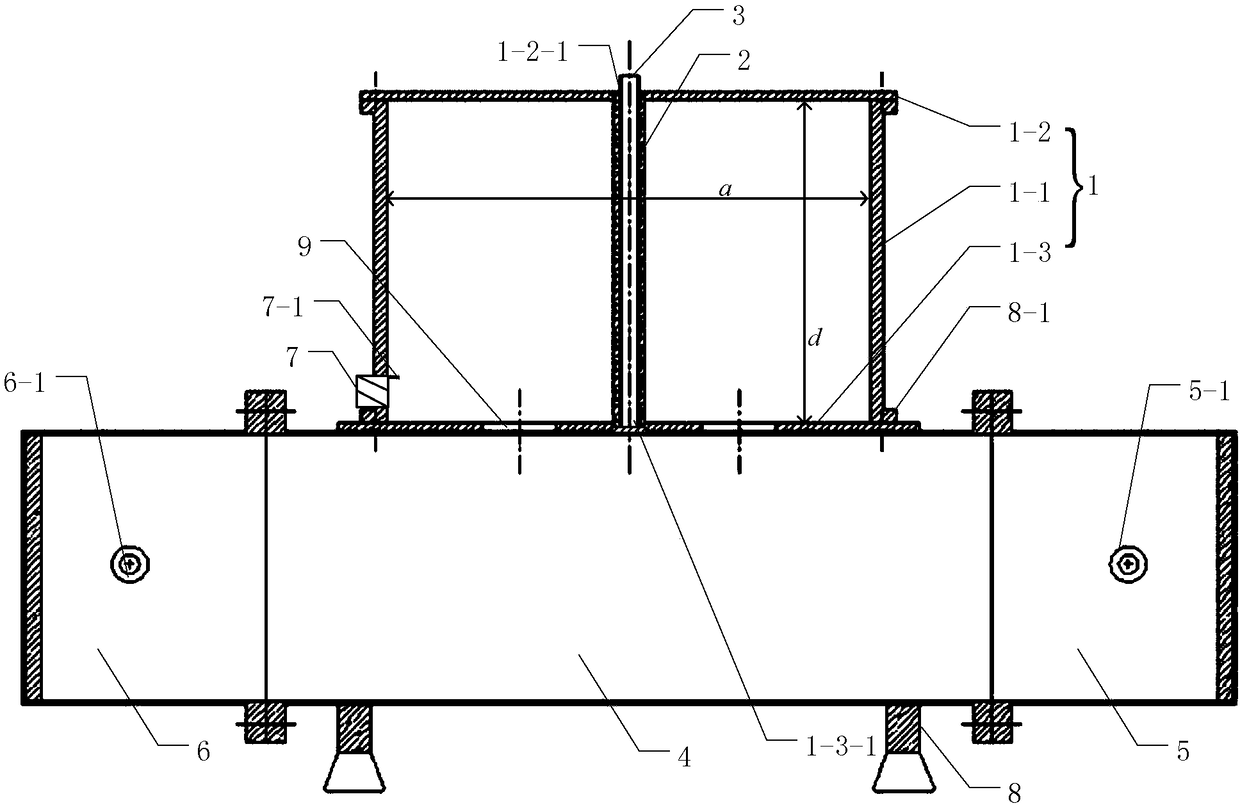

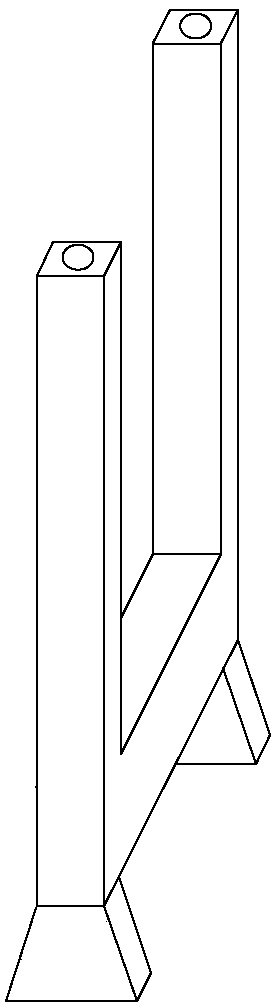

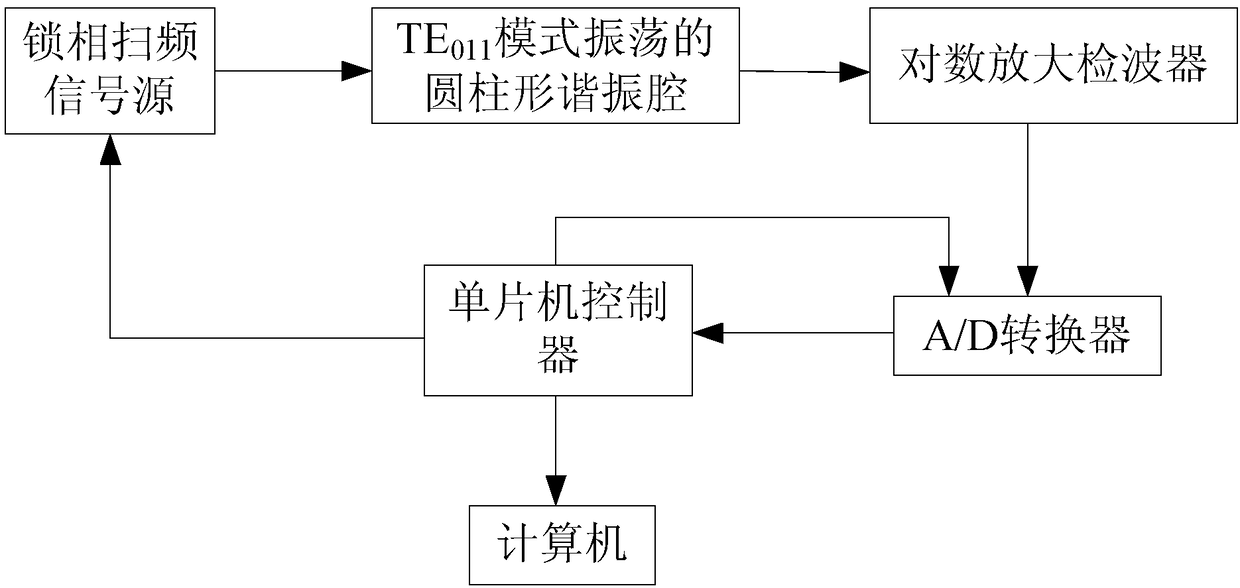

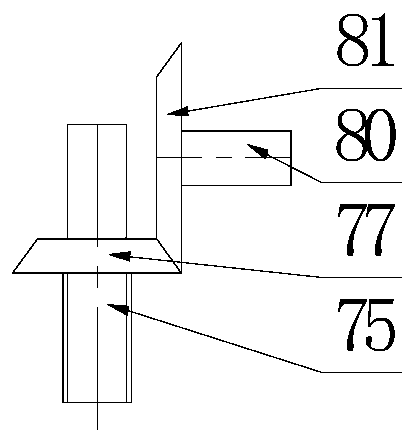

Method for measuring dielectric constant of large loss material

InactiveCN108562798AEnsure consistencyEliminate distractionsResistance/reactance/impedenceResonant cavityDielectric permittivity

The invention provides a method for measuring the dielectric constant of a large loss material, relating to the measurement field of the dielectric constant of the large loss material. According to the method, the problem that a cylindrical resonant cavity perturbation method only can be used for measuring materials with low dielectric constants and low loss is solved. The method comprises the steps of preparing a calibration tube, preparing a to-be-measured sample pipe, measuring the temperature of a solution in the to-be-measured sample pipe, carrying out ascending sequence measurement and descending sequence measurement, correcting the influence of the environmental temperature, determining a resonant cavity calibration equation, and calculating the dielectric constant of a to-be-determined salt solution. The method is suitable for measuring the dielectric constant of the large loss material.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

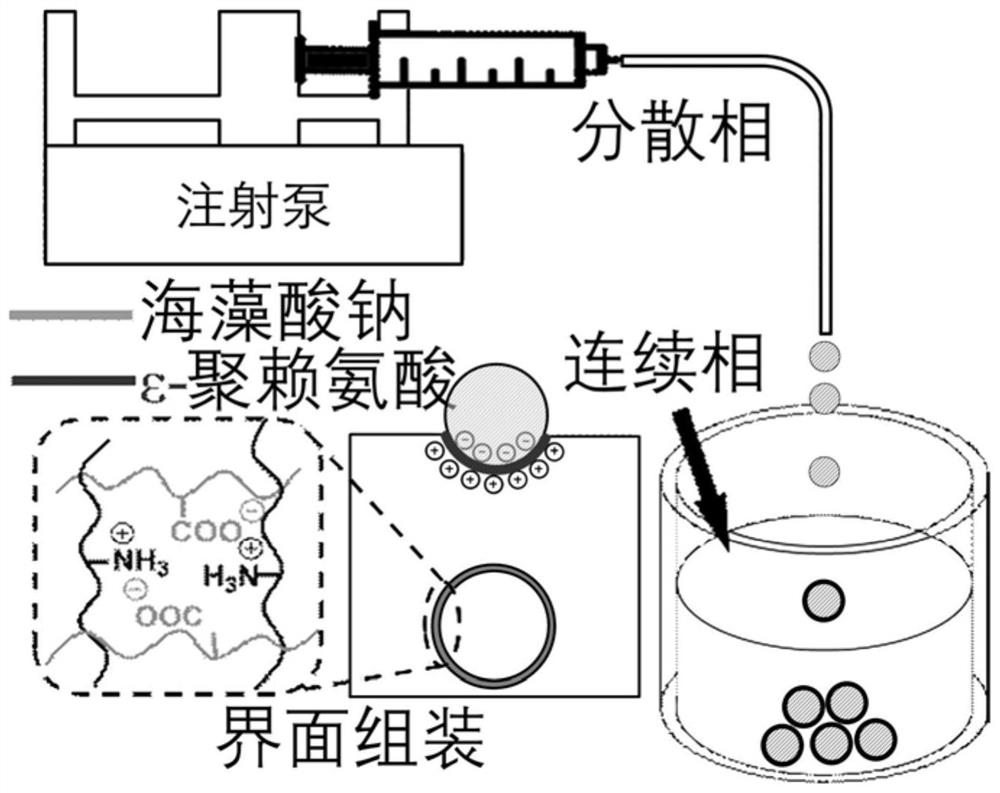

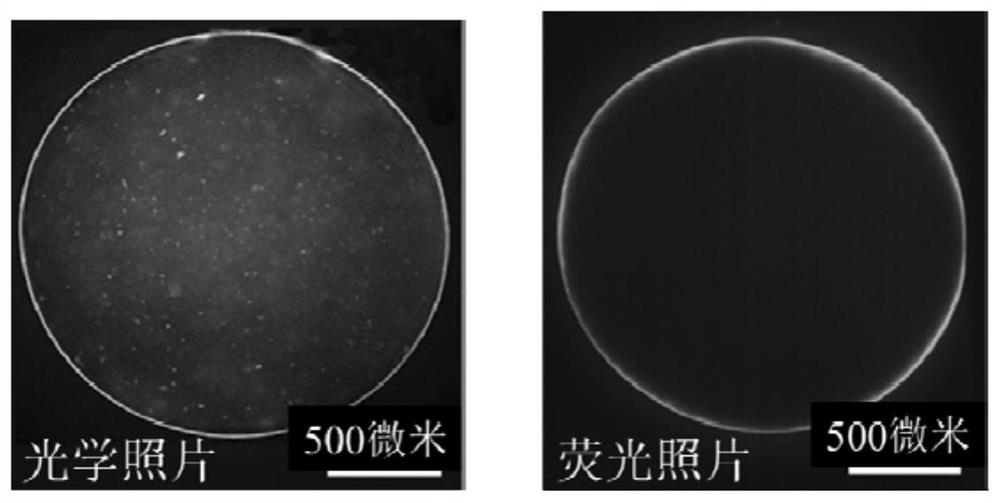

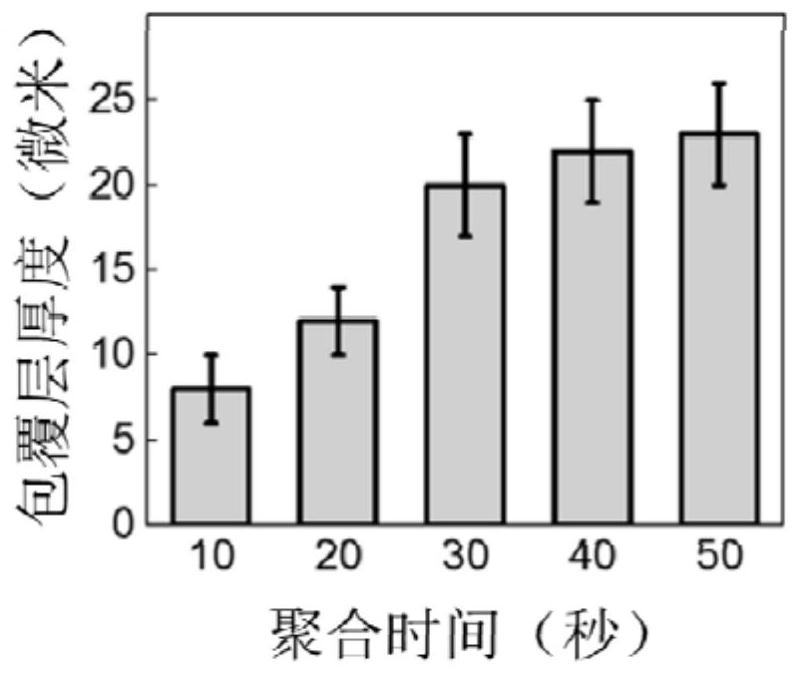

High-transmittance interface assembly core-shell type all-liquid device, preparation method and mechanical property regulation and control method thereof

PendingCN113651967AHigh transparencyIncreased swelling resistanceOrganic active ingredientsPharmaceutical non-active ingredientsLiquid stateAqueous solution

The invention provides a high-transmittance interface assembly core-shell type all-liquid device, a preparation method and a mechanical property regulation and control method of the high-transmittance interface assembly core-shell type all-liquid device. The preparation method comprises the following steps: taking a sodium alginate solution as a dispersion phase and an epsilon-polylysine solution as a continuous phase; adding the dispersion phase into the continuous phase, and obtaining the core-shell type all-liquid device through interface assembly of sodium alginate and epsilon-polylysine. The regulation and control method comprises the following steps: soaking a core-shell type all-liquid device in an aqueous solution containing calcium ions, and curing the core-shell type all-liquid device through Ca<2+>; and washing the cured core-shell type all-liquid device, soaking the cured core-shell type all-liquid device in an aqueous solution of a substance which can compete with Ca<2+> for coordination, and adjusting the concentration of the aqueous solution to obtain the high-transmittance interface assembly core-shell type all-liquid devices with different mechanical properties. According to the preparation method provided by the invention, an all-liquid device with a high-permeability core-shell structure is prepared by utilizing an interface assembly technology.

Owner:香港城市大学深圳研究院

Severe plastic deformation method for grain refinement

A severe plastic deformation method for grain refinement comprises the following steps: 1) a severe plastic deformation channel is formed by employing three modules, wherein a first module is on the bottom and a second module is arranged above the first module to form a first channel, and a third module arranged on the first module and the second module form a second channel; 2) a workpiece to beprocessed is disposed in the first channel, and a vertical pressure is applied on the second module to compact the workpiece to be processed; 3) a push force parallel to the first channel is applied on the third module to drive the second module to move a step along a direction against the first channel, so that the workpiece is extruded into the second channel by a step; 4) the positive pressureapplied on the second module and the third module push force are released to drive the second module and the third module to retreat to initial positions; 5) step 2-4 are repeated to complete extruding. According to the invention, demands of die material and precision by the severe plastic deformation can be lowered, preparative material scope is widened, integrally uniform refinement crystal grains can be obtained, and a workpiece dimension maintains the same after processing.

Owner:BAOSHAN IRON & STEEL CO LTD

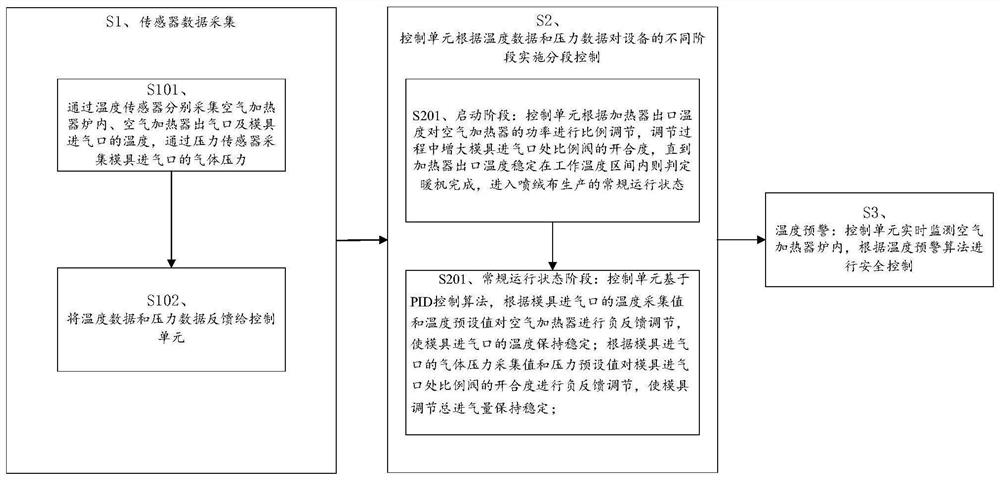

Die head hot air temperature control method and control system applied to melt-blown fabric production

ActiveCN112553698AImprove stabilityQuality improvementSpinning head liquid feederMelt spinning methodsTemperature controlControl system

The invention discloses a die head hot air temperature control method and system applied to melt-blown fabric production. The method comprises the following three steps: S1, collecting sensor data; S2, carrying out segmented control on different stages of equipment according to temperature data and pressure data by a control unit, wherein the stages comprise a starting stage and a conventional operation stage; and S3, carrying out temperature early warning. The system comprises a plurality of temperature sensors, a pressure sensor and a control unit, wherein the temperature sensors are used for being installed in an air heater furnace and at an air heater air outlet and a mold air inlet correspondingly, the pressure sensor is used for being installed at the mold air inlet, the control unitcontrols an air heater and a die through the die head hot air temperature control method applied to melt-blown cloth production. On one hand, the production stability and product quality of the melt-blown fabric are improved, and the available material range of the equipment is expanded; and on the other hand, damage caused by high heat generated by improper control of the die and other equipmentis avoided, and the die life is prolonged.

Owner:SHENZHEN LEADWELL TECH CO LTD

Piston rod and production method thereof as well as carbonitriding agent for piston rod surface treatment

ActiveCN102492918BSimple recipeLow costSolid state diffusion coatingPiston rodsThioureaBarium carbonate

The invention relates to a piston rod and a production method thereof as well as a carbonitriding agent for piston rod surface treatment. The carbonitriding agent comprises the following components by weight percent: 20-24% of urea, 13-15% of thiourea, 10-14% of barium acetate, 24-27% of calcium carbonate, 22-26% of barium carbonate and 4-10% of lithium carbonate. The carbonitriding layer tissue comprises an oxide layer, a tectorium, a compound layer, an Austria layer and a diffusion layer. The carbonitriding agent has the beneficial effects of simple formula and low cost; the piston rod produced by using the carbonitriding agent is smooth in surface, low in roughness and is airproof, the piston rod compound carbonitriding layer is more than 32mu m in thickness and has the characteristics of high corrosion resistance and abrasion resistance, low rejection ratio and long service life; in the piston rod production process, thermal treatment and anti-corrosion treatment are completed once, treatment temperature is between 600 DEG C-700 DEG C, the piston rod production process has the advantage of optimizing the machining process; and nitriding time is shortened to 30-50 minutes, production period is shortened, and production cost is reduced.

Owner:QINGDAO ZHANGSHI MACHINERY

A kind of formula of culture material of edible fungus branch strain and the preparation method of the culture material

ActiveCN104221718BIncrease profitExtended range of materialsHorticultureFertilizer mixturesBiotechnologyOyster

The invention discloses a formula of edible fungi branch strain compost. The formula is characterized in that 12 sticks to 18 stick of reed stalks, 50 g to 75 g of grains and 20 g to 30 g of auxiliary materials are arranged in each special strain bottle with the specification being 750 ml. Meanwhile, the invention provides a preparation method of the strain compost. The preparation method includes the steps of selecting materials, soaking, washing and rinsing, bottling, sterilizing and cooling and inoculating. According to the formula of the edible fungi branch strain compost and the preparation method of the strain compost, the hollow feature of the reed stalks is utilized, the reed stalks are filled with grains, advantages of grain strains and branch strains are integrated effectively, and thus the mycelial growth speed is higher, and synchronism is higher; furthermore, the utilization rate of the reeds is increased, the material range of the branch strains is broadened, good effects on accelerating the spawn runing speed and shortening the spawn runing time are achieved, and the edible fungi branch strain compost can be used for culturing stock seeds and cultivated species of various wood rotting edible fungi such as mushrooms, oyster mushrooms, agarics, needle mushrooms, pleurotus eryngii and lucid ganoderma.

Owner:TANGYIN EDIBLE FUNGUS RES INST

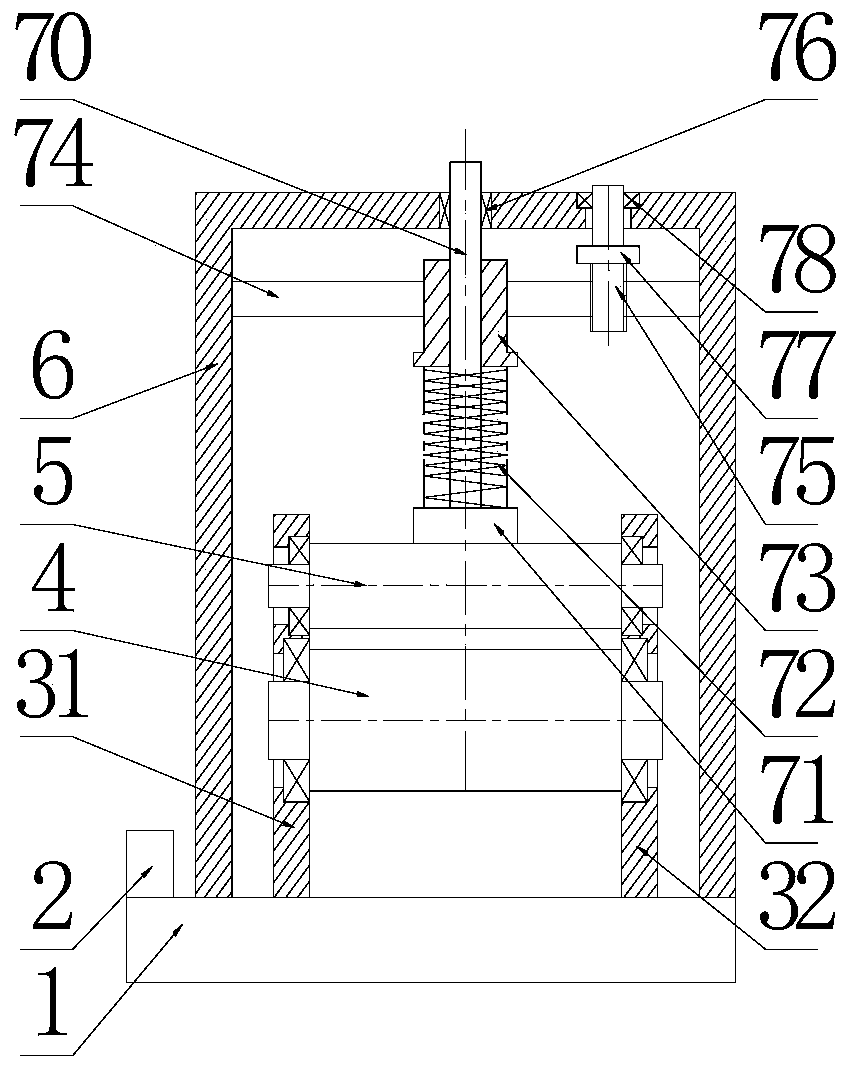

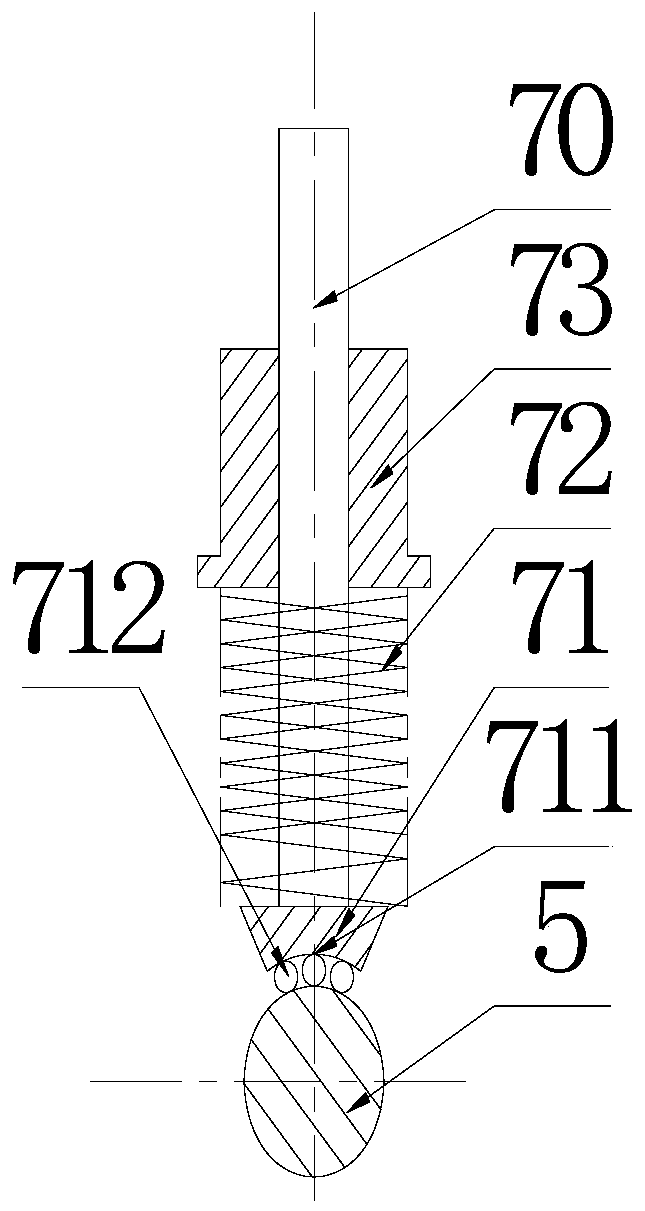

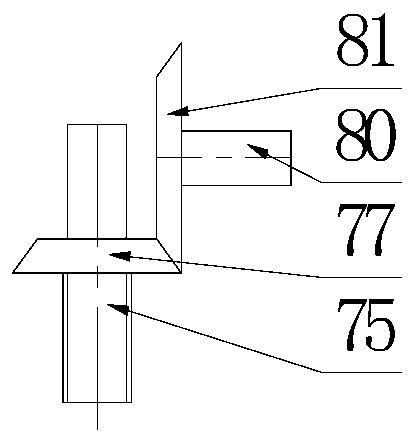

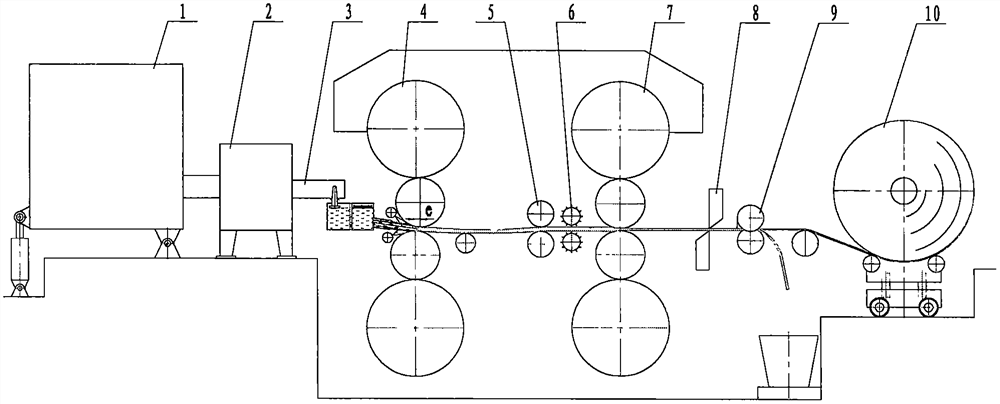

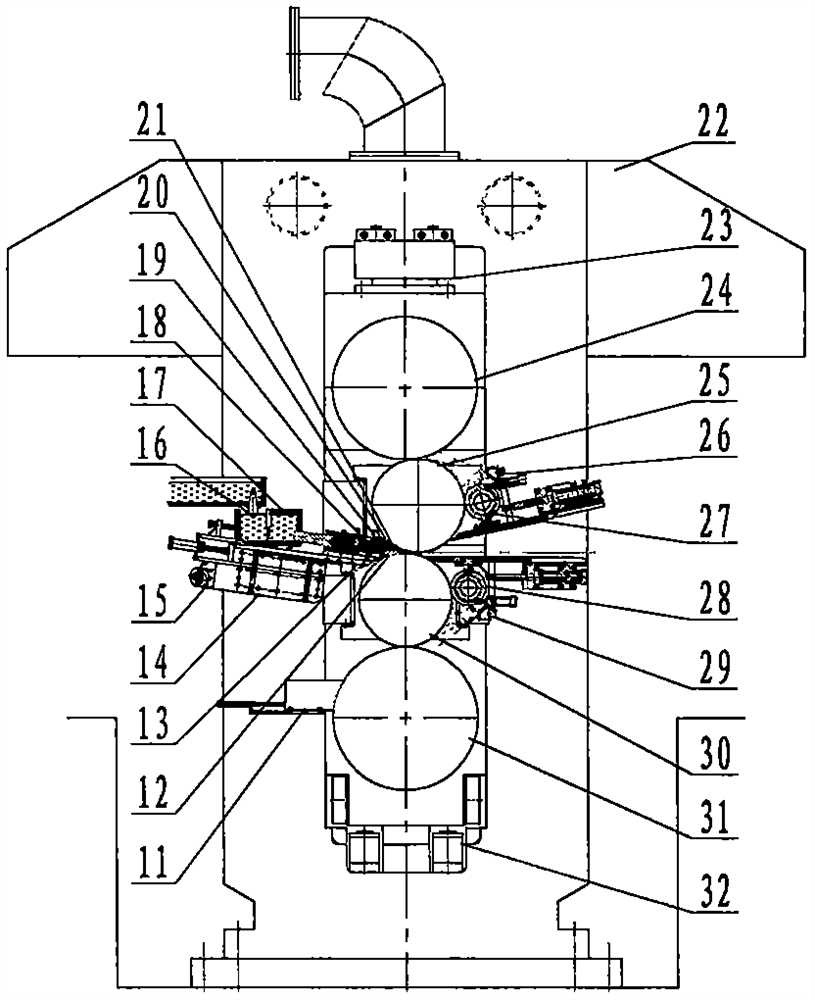

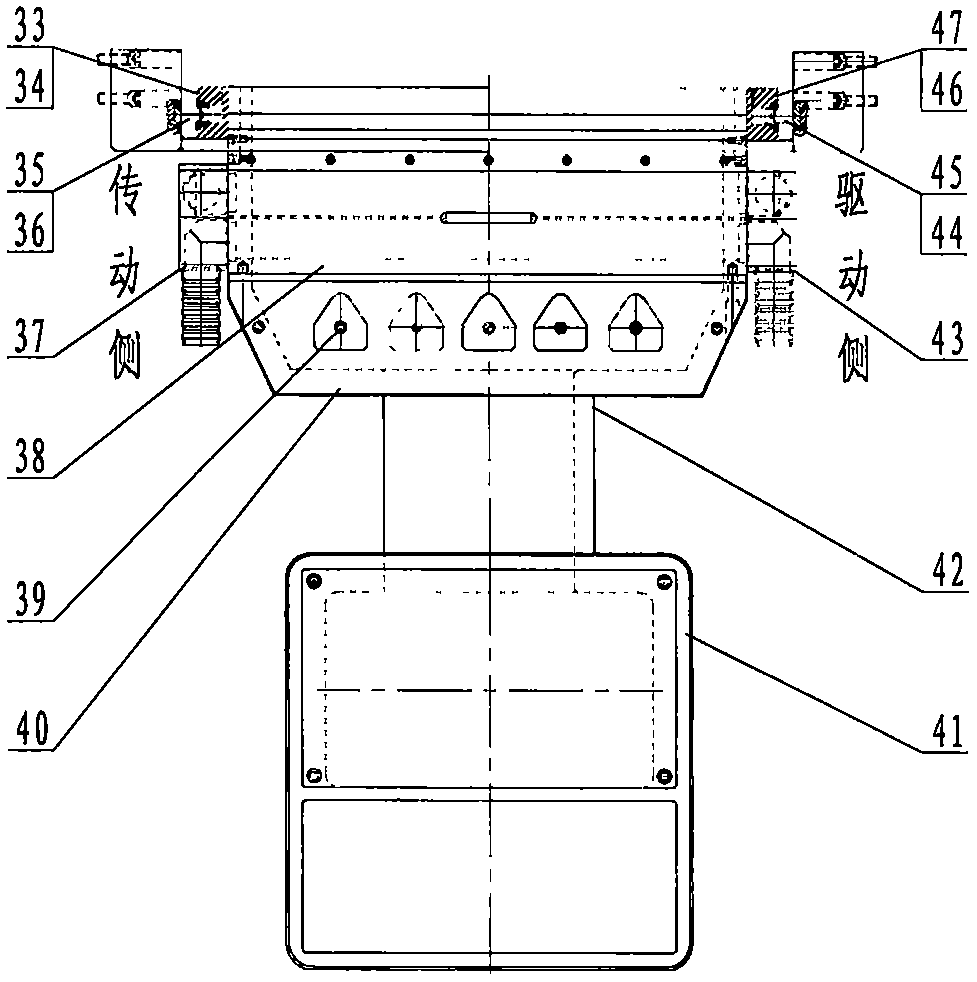

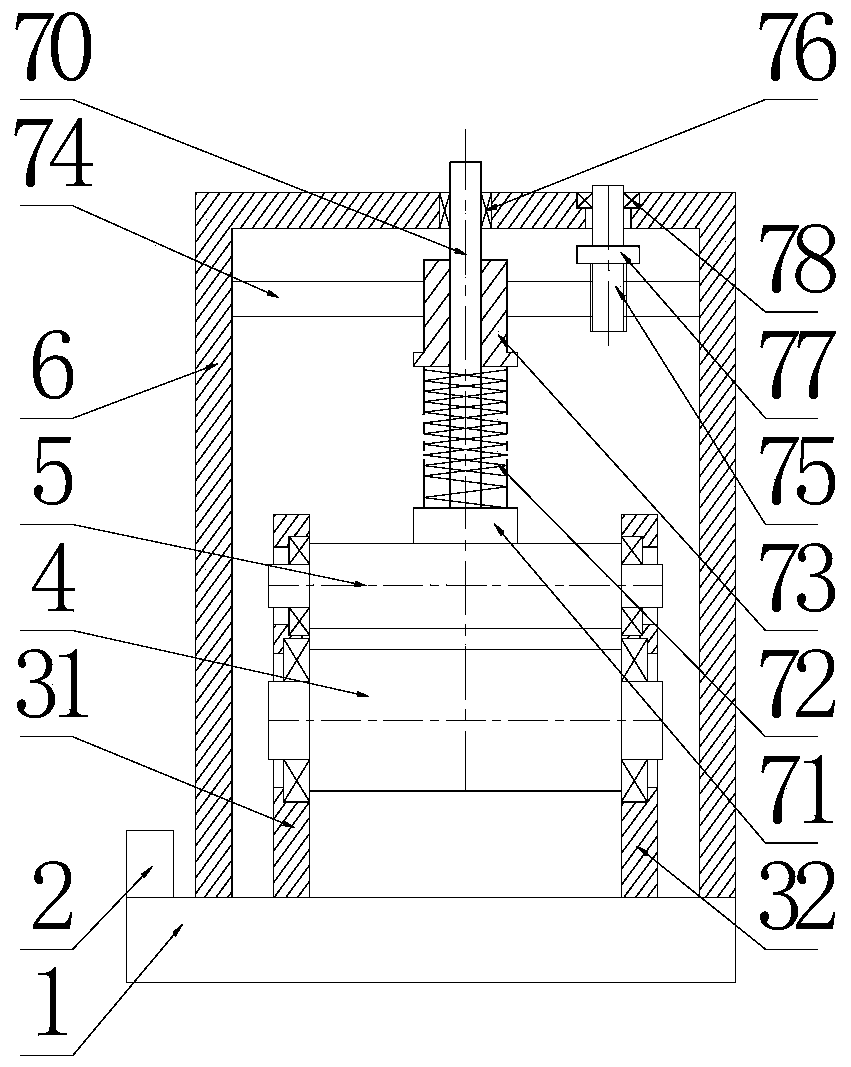

Rolling mill for adjusting pressure compensation deflection

ActiveCN110153193ASimple structureExtended range of materialsMetal rolling stand detailsMetal rolling arrangementsControl systemRolling mill

The invention discloses a rolling mill for adjusting a pressure compensation deflection, and belongs to the field of rolling mills. The rolling mill comprises a machine base, a roller bearing seat A,a roller bearing seat B, a lower roller, an upper roller and a control system, wherein the two ends of the lower roller and the upper roller are correspondingly arranged on the roller bearing seat A and the roller bearing seat B through bearings and are arranged in parallel; the rolling mill further comprises a pressure adjusting device, wherein the pressure adjusting device comprises a compensation pressure plate with an arc-shaped contact surface, a lifting rod fixedly arranged on the compensation pressure plate, a spring pressure applying plate capable of moving up and down along the lifting rod, a linear rigidity spring arranged on the lifting rod and located between the spring pressure applying plate and the compensation pressure plate and a lifting plate which is arranged on the machine base and can move up and down relative to the machine frame; and the spring pressure applying plate is fixedly arranged on the lifting plate. The rolling mill has the advantages that the structureis simple and reasonable, the pressure compensation deflection can be adjusted, the thickness of the steel rolling is more uniform, and the deflection of the pressure compensation can be adjusted.

Owner:CHANGZHOU UNIV

Metal casting and continuous rolling method and equipment capable of achieving melt distribution and heat exchange separation in crystallizer

ActiveCN113857446AImprove cooling effectSolve Oxidation ProblemsMetal rolling arrangementsProcess engineeringHeat conservation

The invention discloses a metal casting and continuous rolling method and equipment capable of achieving melt distribution and heat exchange separation of a crystallizer, and relates to a method and equipment for producing a metal plate blank. The online moving water-cooled crystallizer with melt distribution and heat exchange function separation is in butt joint with a roller before production, and is separated from the roller during production; according to the production condition, water can be selectively sprayed to the outside of a heat exchanger, and the casting blank heat dissipation capacity is further improved; and the crystallizer composed of a distributor and the heat exchanger solves the contradiction that heat preservation is achieved in the plate erecting process and heat conductivity is good in the production process through melt distribution and heat exchange function separation. In addition, after the split type crystallizer is used for production, a residual metal oxide film in a runner can be conveniently removed; the surface of a casting blank can be prevented from being adhered to the inner wall of the heat exchanger through online movement of the crystallizer; and according to a crystallizer sealing mechanism, under the condition that the crystallizer is separated from the roller, the casting blank does not make contact with air before rolling, in the plate thickness adjusting process and in the rolling process, and the problem that the surface of the casting blank is oxidized in the production process is effectively solved.

Owner:张明

A rolling mill for adjusting pressure and compensating deflection

ActiveCN110153193BSimple structureExtended range of materialsMetal rolling stand detailsMetal rolling arrangementsControl systemEngineering

The invention discloses a rolling mill for adjusting a pressure compensation deflection, and belongs to the field of rolling mills. The rolling mill comprises a machine base, a roller bearing seat A,a roller bearing seat B, a lower roller, an upper roller and a control system, wherein the two ends of the lower roller and the upper roller are correspondingly arranged on the roller bearing seat A and the roller bearing seat B through bearings and are arranged in parallel; the rolling mill further comprises a pressure adjusting device, wherein the pressure adjusting device comprises a compensation pressure plate with an arc-shaped contact surface, a lifting rod fixedly arranged on the compensation pressure plate, a spring pressure applying plate capable of moving up and down along the lifting rod, a linear rigidity spring arranged on the lifting rod and located between the spring pressure applying plate and the compensation pressure plate and a lifting plate which is arranged on the machine base and can move up and down relative to the machine frame; and the spring pressure applying plate is fixedly arranged on the lifting plate. The rolling mill has the advantages that the structureis simple and reasonable, the pressure compensation deflection can be adjusted, the thickness of the steel rolling is more uniform, and the deflection of the pressure compensation can be adjusted.

Owner:CHANGZHOU UNIV

A kind of dye-sensitized solar cell photoanode and preparation method thereof

ActiveCN103346017BWon't happenEasy to operateLight-sensitive devicesFinal product manufactureFiberSolar cell

The invention discloses a dye-sensitized solar cell photo anode. The photo anode does not comprise ITO and other transparent conductive oxide, surface nickel plating fibers are used as a conductive substrate, and titanium oxide and zinc oxide are used as semiconductor oxide. The preparation process of the photo anode comprises the steps that a metallic nickel layer is deposited on the surface of a metal wire or a non-metal wire, a titanium oxide and zinc oxide semiconductor film is then prepared on the surface of the metal wire or the non-metal wire, the metal wire or the non-metal wire is soaked in dye to be sensitized for 20 hours after being dried, and the dye-sensitized photo anode is obtained. The low-cost metallic nickel fiber photo anode can be manufactured through a simple full-wet process, the method is simple in operation, the requirement for equipment is not high, and production cost is relatively low; the dye-sensitized solar cell photo anode is firstly applied to fiber DSSC cells, and good photoelectric properties are obtained. A similar technology can be applied to other conductive substrates, and therefore a large class of photo anode substrate materials can be achieved.

Owner:CHONGQING UNIV

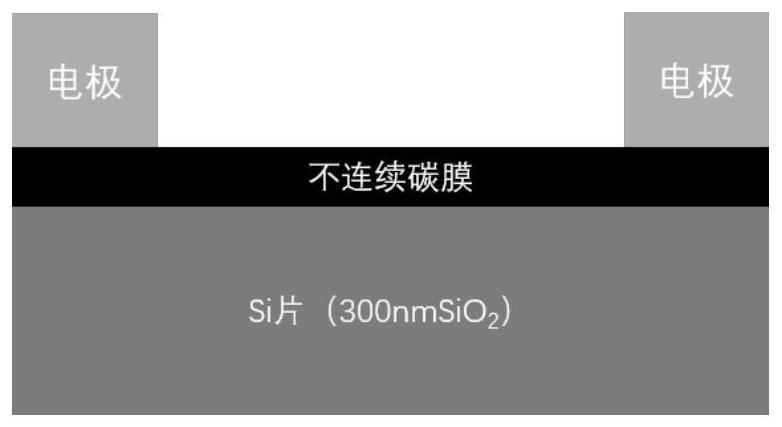

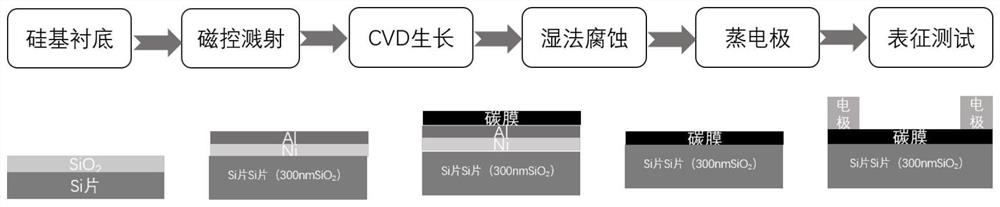

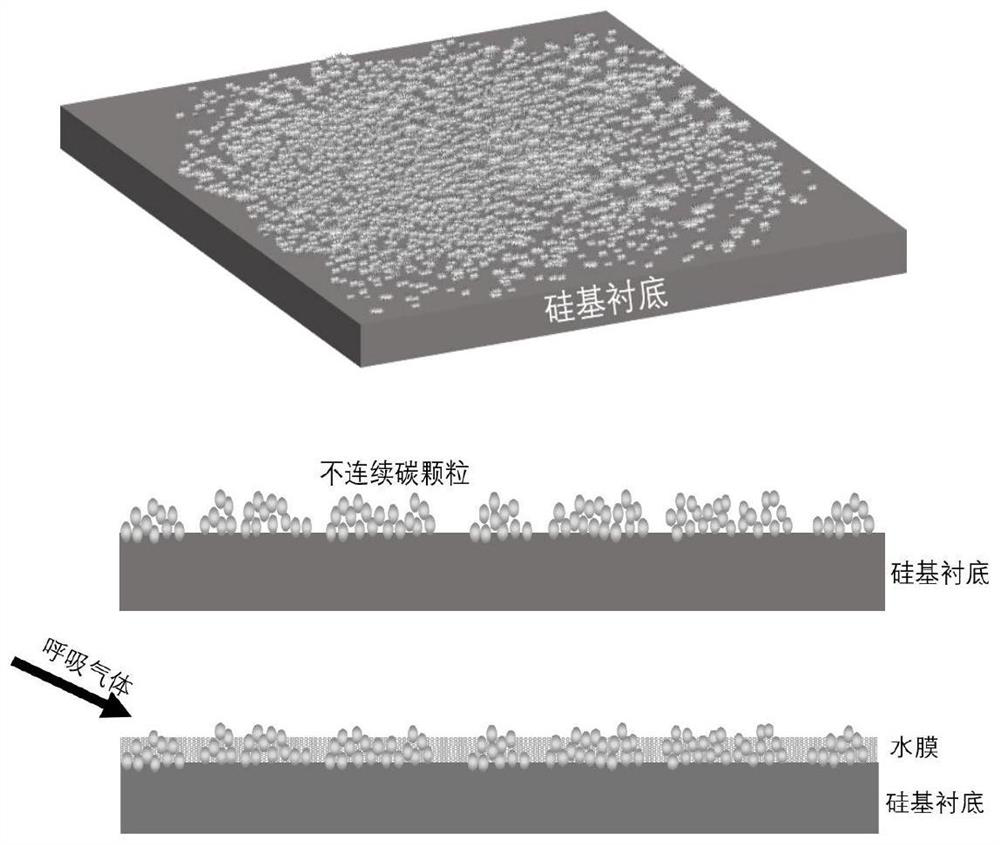

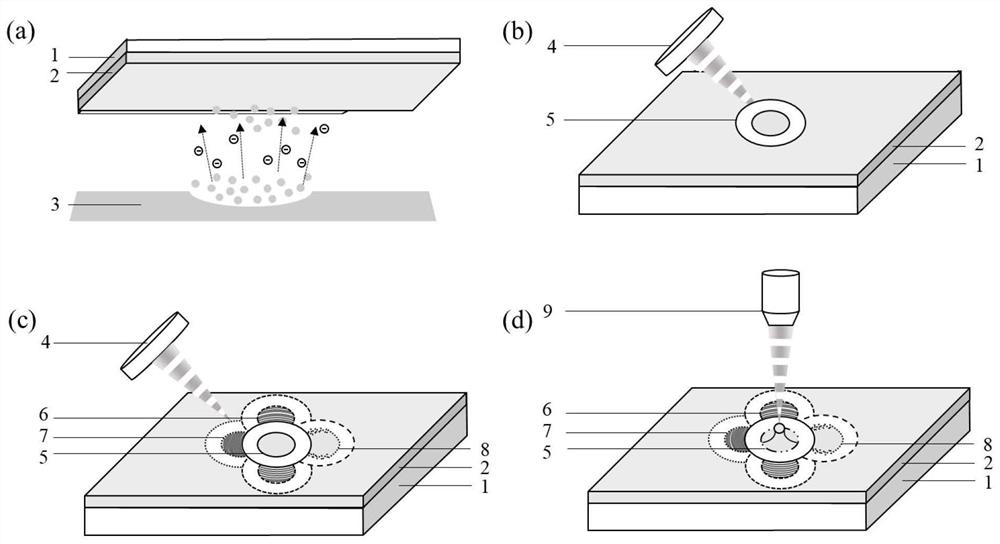

Preparation of discontinuous carbon film based on aluminum-nickel metal layer and application of discontinuous carbon film to respiration sensor

PendingCN114107940AImprove solubilityLow conductivityVacuum evaporation coatingSputtering coatingCarbon filmTitanium electrode

The invention discloses preparation of a discontinuous carbon film based on an aluminum-nickel metal layer and application of a respiration sensor, and belongs to the technical field of carbon film preparation. In the preparation process of the carbon film, firstly, aluminum-nickel metal layers with different components are sputtered on the surface of a silicon-based substrate by a magnetron sputtering method, and part of nickel catalytic active sites are passivated by adding aluminum, so that the carbon film with a discontinuous structure is obtained after growth by a CVD (Chemical Vapor Deposition) method; and removing the aluminum-nickel catalytic metal layer on the silicon-based substrate by adopting a wet etching method to obtain the discontinuous carbon film directly falling on the substrate. A conductivity test carried out by evaporating a titanium electrode shows that the carbon film has relatively sensitive responsiveness to respiration, the device is changed from a non-conductive state to a conductive state when external humidity changes such as respiration, and the carbon film has relatively good response sensitivity and can be used for developing and preparing a wearable respiration monitoring device with high sensitivity and low power consumption.

Owner:BEIJING UNIV OF TECH

Multilayer film heterostructure, its preparation method and application

ActiveCN106784299BEliminate distractionsExplicit detectionGalvano-magnetic devicesThermoelectric device with peltier/seeback effectHeterojunctionSpin Hall effect

The invention provides a multilayer film heterogeneous structure, its preparation method and application. The multi-layer heterogeneous structure provided by the present invention can eliminate the interference of other thermomagnetic effects, and clearly and effectively detect the inverse spin Hall effect ISHE and the anomalous Nernst effect ANE of the spin current detection layer, as well as the anomalous Rigi-Ledoux The Gram effect ARL is separated, which reduces the reflection of the spin current at the interface, and realizes the measurement of the longitudinal spin Seebeck effect at room temperature; and does not limit the coercive force of the spin current detection layer material, expanding the available range of materials for practical applications.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

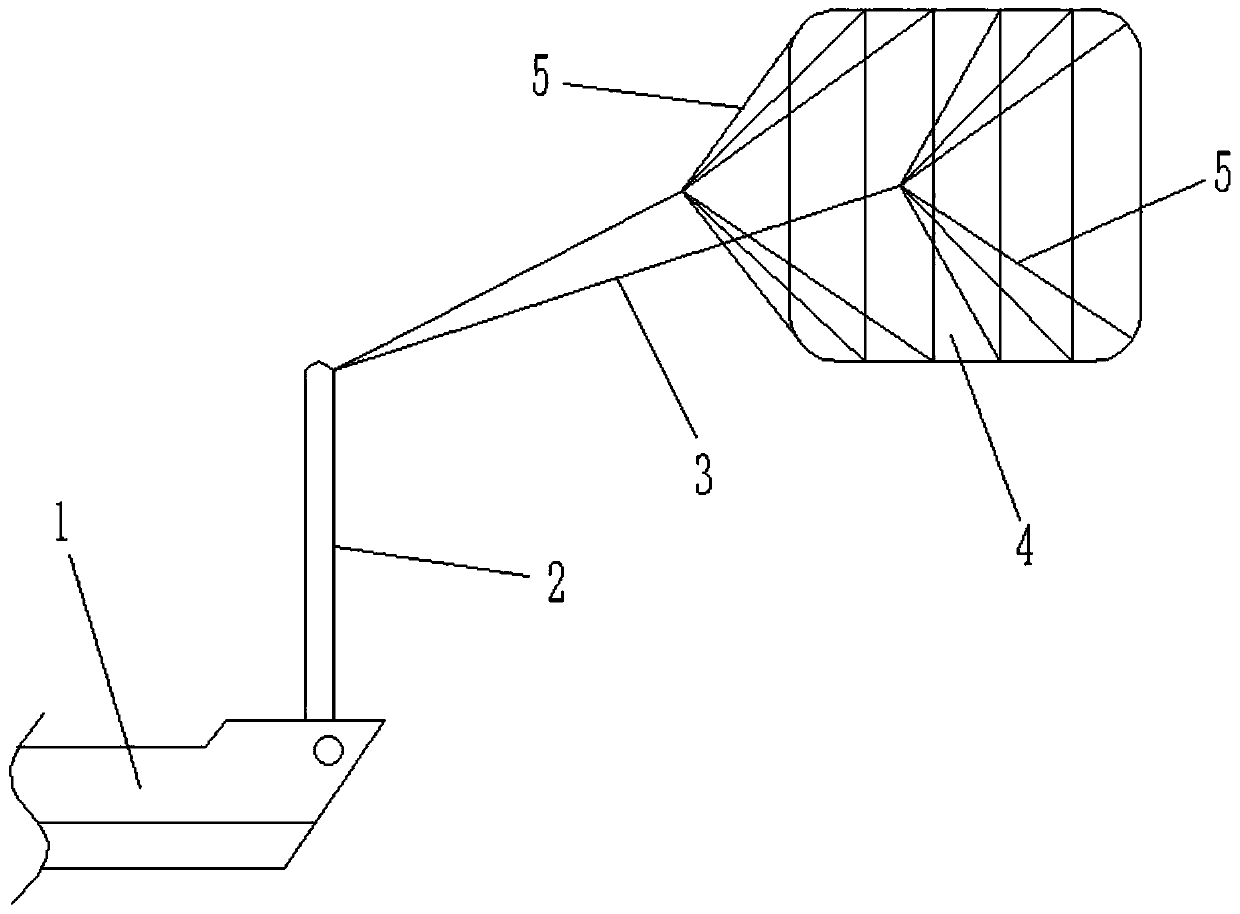

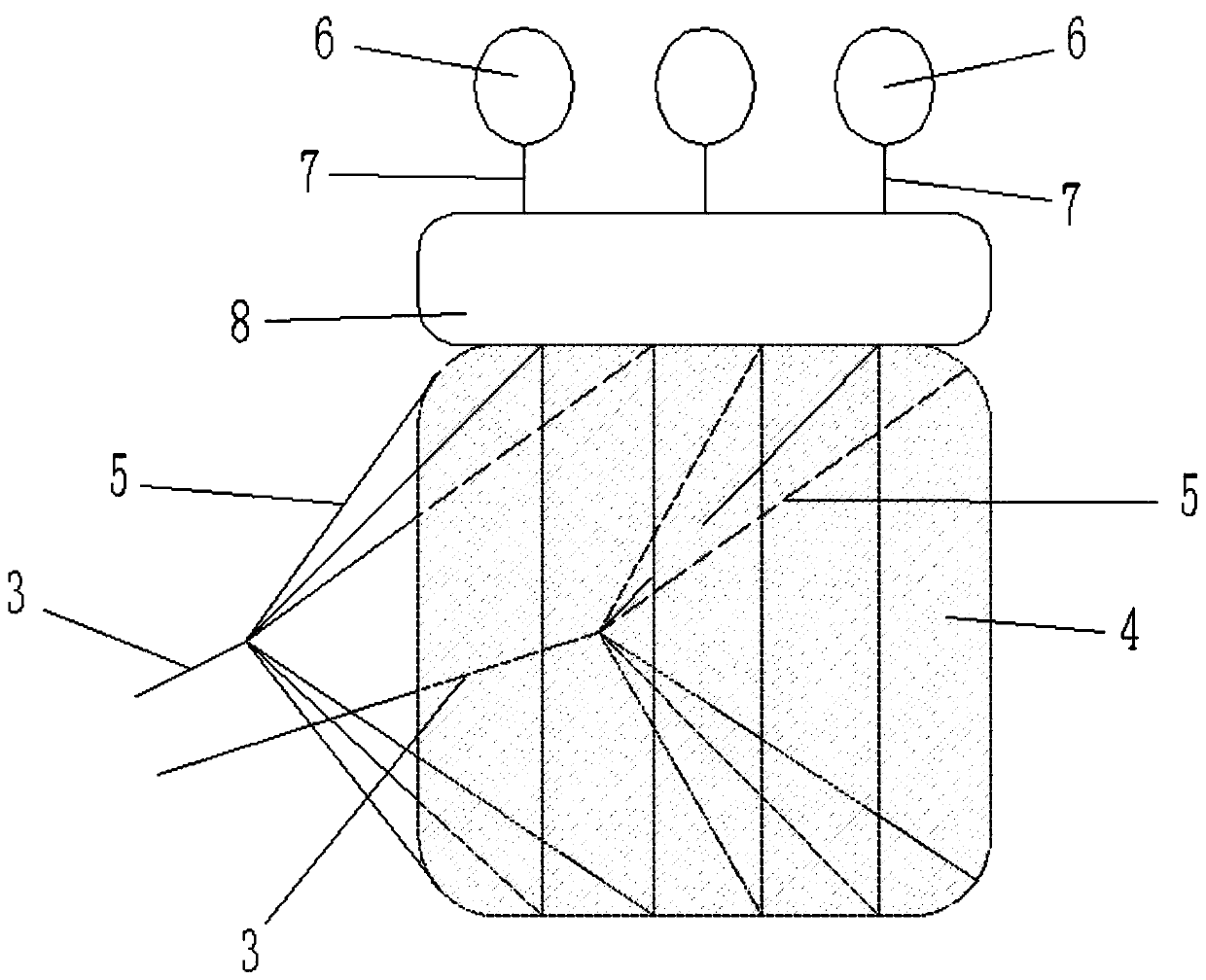

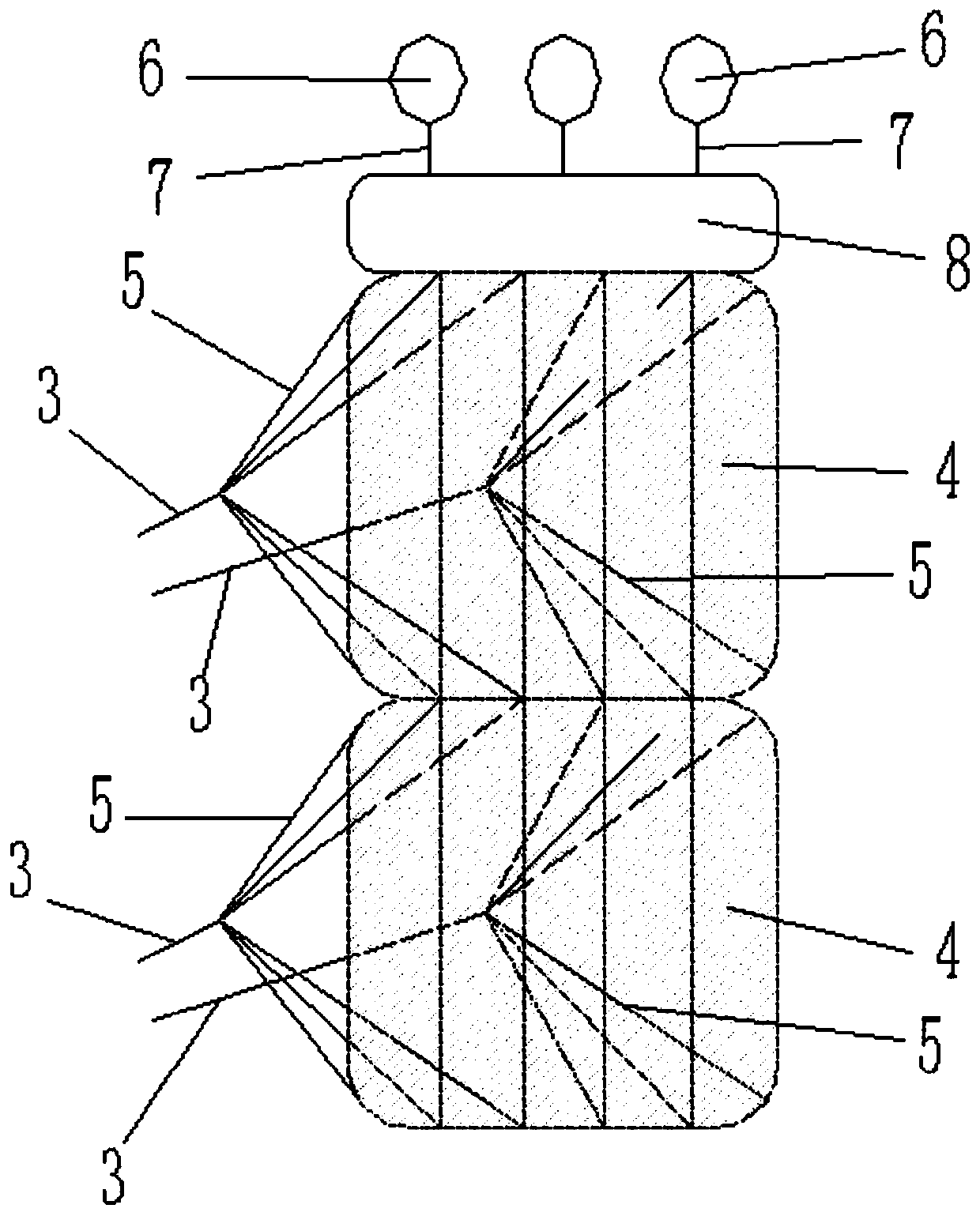

Inflatable sail system

InactiveCN111559484AEffective promotionPromoted smoothlyWind acting propulsive elementsMechanical engineeringPhysics

The invention discloses an inflatable sail system comprising a mast fixed to a deck, a sail, a take-up and pay-off line and a take-up and pay-off connecting line. The sail has a soft structure composed of two layers of cloth with edges connected with each other, and the two layers of cloth of the sail are made of parachute nylon cloth; the top of the sail is connected with a first air bag, and thefirst air bag is filled with gas with the density smaller than the air density. The first air bag is filled with hydrogen or helium; an inflating hole is formed in the first air bag; the top of the first air bag is connected with a second air bag, and the second air bag is filled with gas with the density smaller than the air density. The parachute nylon cloth is used as the material of the sail;compared with an existing sail material, the provided inflatable sail system enables the cost to be effectively saved; meanwhile, in order to enable the sail to rise into the high altitude more effectively, gas with the density smaller than the air density is used, so that the sail can be driven by air buoyancy to smoothly rise into the air.

Owner:赵珂正

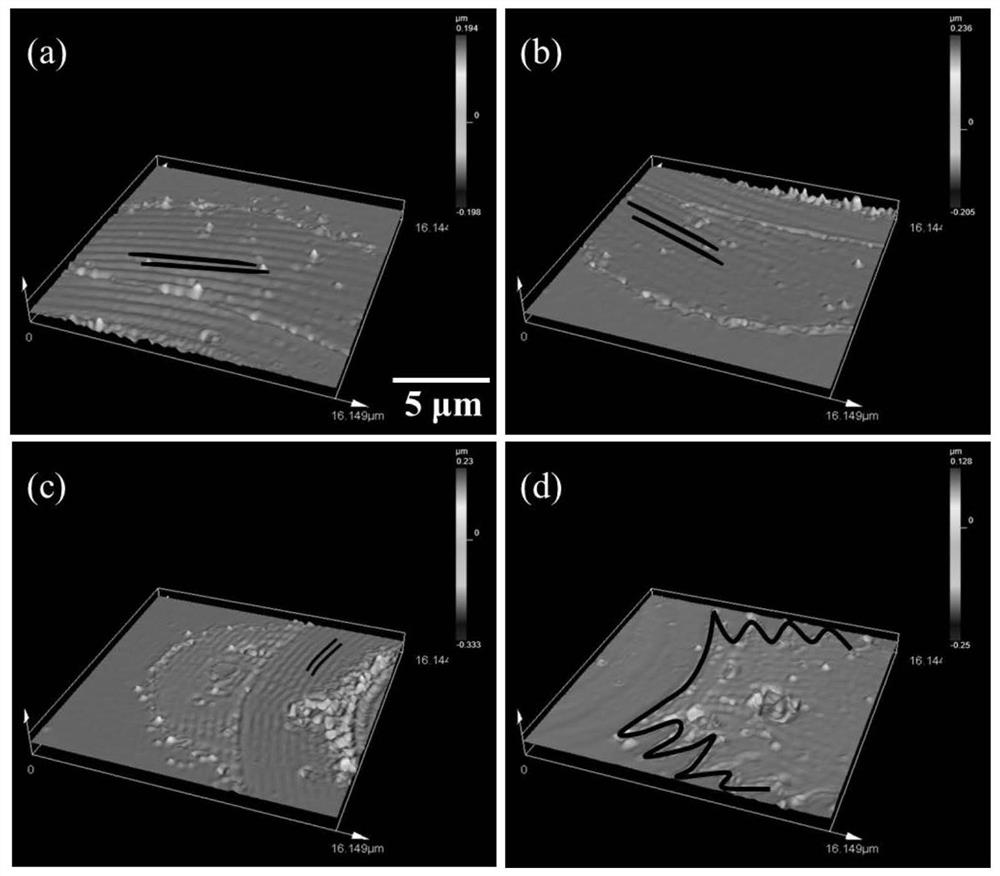

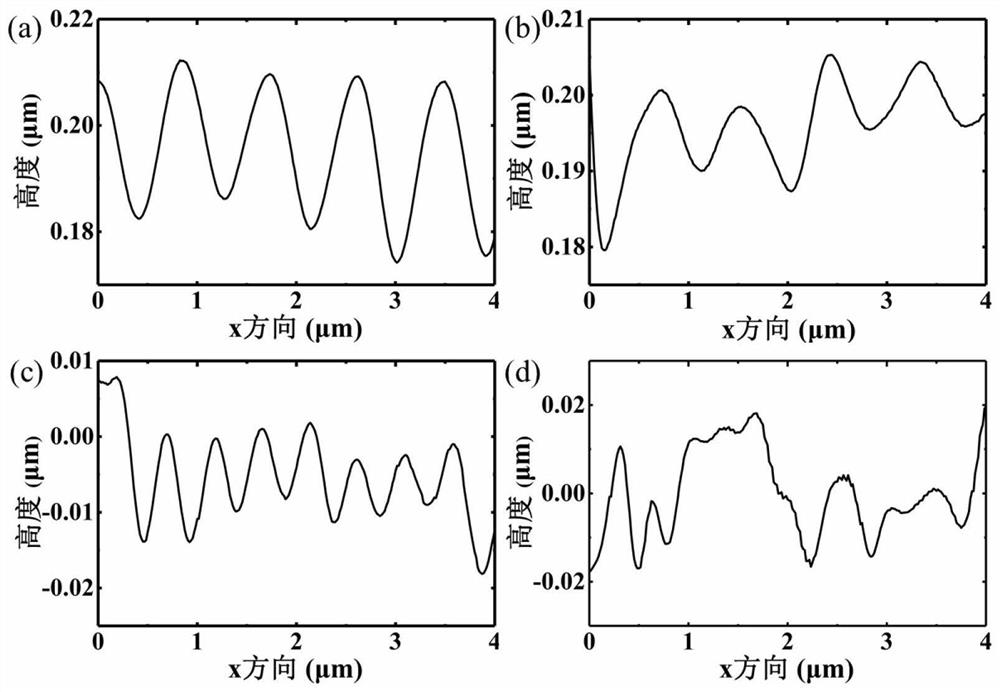

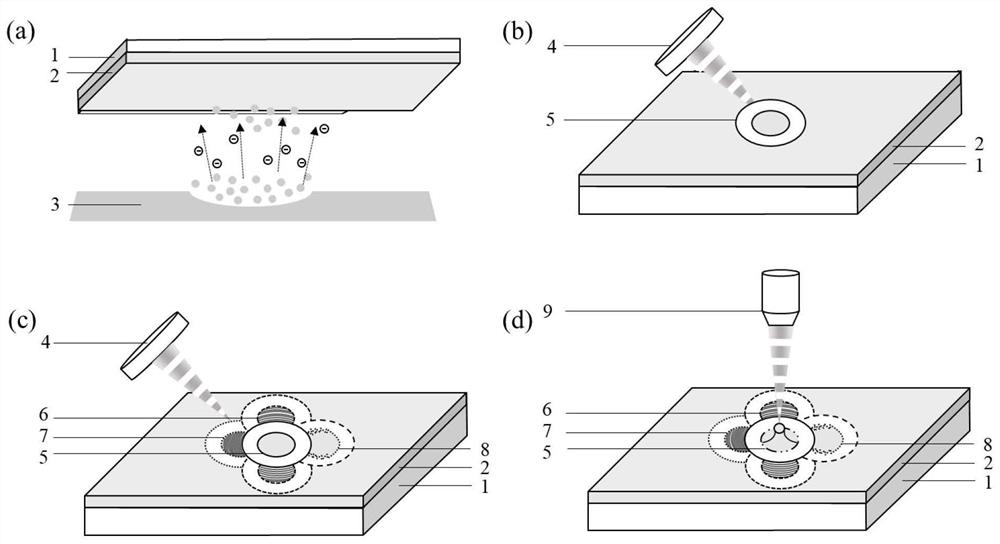

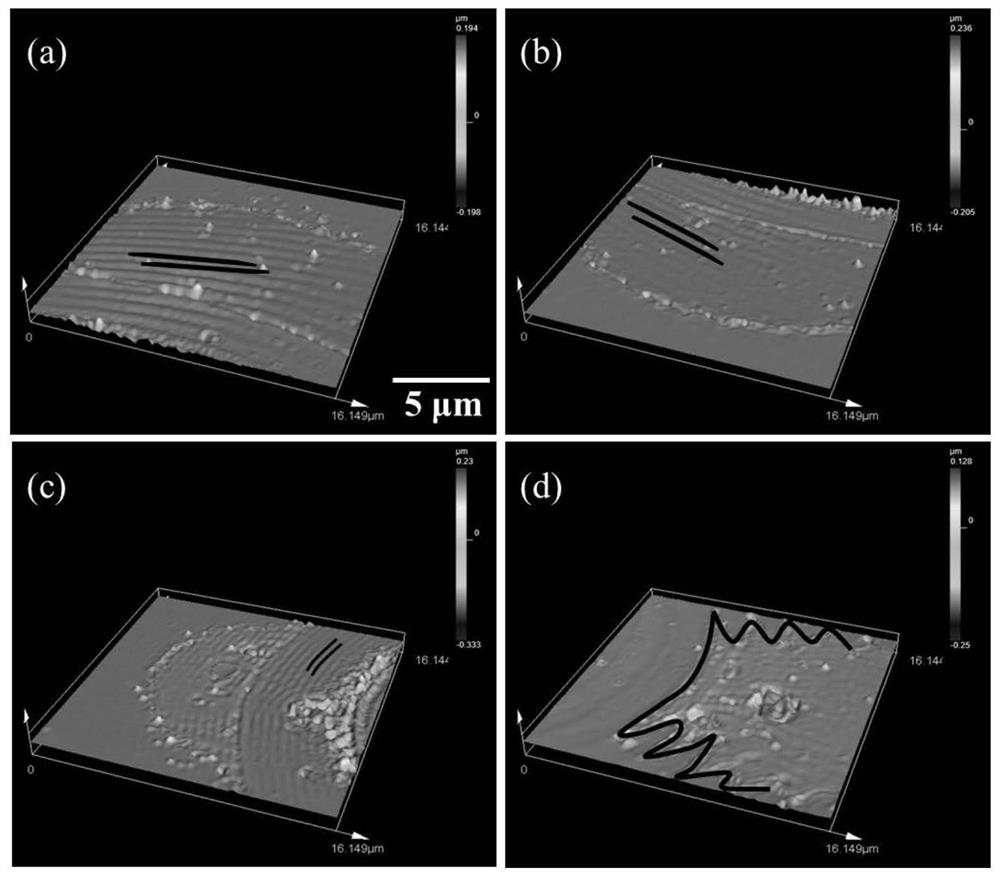

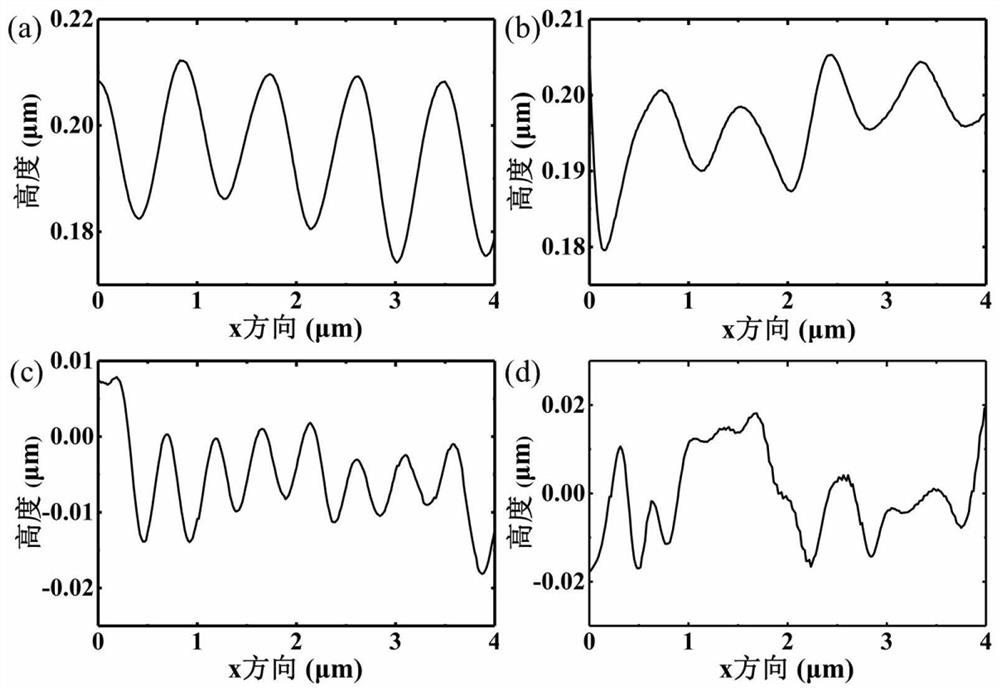

Method for simply preparing multi-band near-field enhanced composite nano antenna

ActiveCN112928465ASolve the limitation of a single near-field enhancement bandAvoid energy lossVacuum evaporation coatingRadiating elements structural formsLaser processingFemto second laser

The invention relates to a method for simply preparing a multi-band near-field enhanced composite nano antenna, and belongs to the technical field of laser processing application. Single-point processing is carried out through oblique incidence focusing femtosecond laser, follow-up pulse dislocation processing is regulated and controlled, the offset direction is adjusted, the micro-nano grating structure can be manufactured by simply controlling the femtosecond laser and changing the period of the micro-nano grating structure without the help of additional conditions by utilizing the arbitrariness of the included angle between the edge of the preorder structure and the femtosecond laser, and then, focusing processing is performed by using an objective lens to obtain nano jet particles to prepare the composite nano antenna capable of performing near-field enhancement in multiple wavebands. According to the method, the limitation of single near-field enhancement wave band of the nano antenna at present is solved, the method for preparing the micro-nano grating and changing the period of the micro-nano grating through femtosecond laser oblique incidence dislocation single-point processing is simple and easy to implement, the influence of a liquid environment or other processing environments on a sample is avoided, and the method can be widely applied to the fields of optical communication, sensing, nano photoelectric devices and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A simple method for preparing multi-band near-field enhanced composite nanoantennas

ActiveCN112928465BSolve the limitation of a single near-field enhancement bandAvoid energy lossVacuum evaporation coatingSputtering coatingLaser processingFemto second laser

The invention relates to a simple method for preparing a multi-band near-field enhanced composite nano-antenna, which belongs to the technical field of laser processing applications. The invention performs single-point processing by obliquely incident focused femtosecond laser, regulates subsequent pulse dislocation processing and adjusts the offset orientation, utilizes the randomness of the included angle between the edge of the preorder structure and the femtosecond laser, and can pass simple Control the femtosecond laser to manufacture the micro-nano grating structure and change its period, and then use the objective lens to focus and process to obtain nano-jet particles, and prepare a composite nano-antenna that can perform near-field enhancement in multiple bands. The present invention solves the single limitation of the near-field enhancement band of the current nano-antenna, and the method of preparing the micro-nano grating and changing its period by using a femtosecond laser oblique incident dislocation single-point processing is simple and easy, and avoids the liquid environment or other processing environments causing damage to the sample. It can be widely used in optical communication, sensing, nano-optoelectronic devices and other fields.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

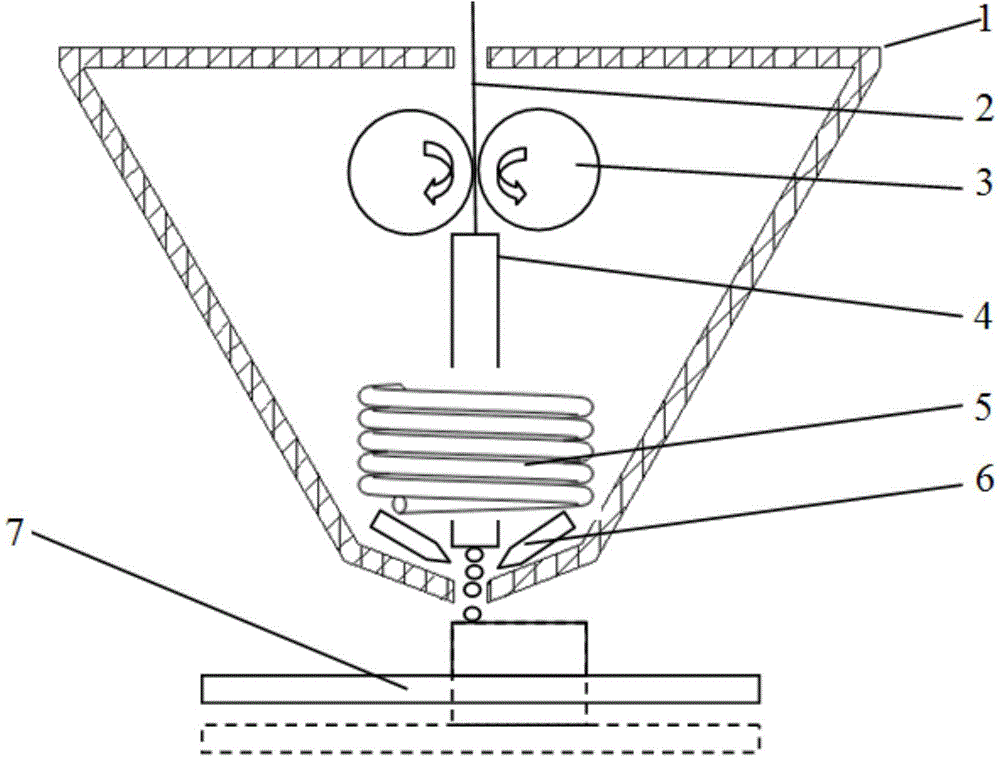

Metal wire material additive equipment and material additive method based on alternating magnetic field

ActiveCN104174842BLow costSimple production equipmentAdditive manufacturing apparatusNumerical controlShielding gas

The invention provides a metal wire material additive equipment based on an alternating magnetic field, which at least includes a numerical control device, a substrate, and a deposition head. Both the substrate and the deposition head are installed on the numerical control device, and the substrate is located on the deposition head. Below, the deposition head includes a shielding shell and a wire wheel installed on the shielding shell, the wire is wound on the wire wheel, and a wire feed wheel, a ceramic guide tube, an alternating magnetic field coil and a shielding gas are arranged inside the shielding shell The top of the shielding shell has a wire inlet, the wire feed wheel is installed below the wire inlet, the ceramic guide tube is vertically fixed below the wire feed wheel, and the alternating magnetic field coil is wound on the ceramic guide on the outer wall of the lower part of the tube. At the same time, the present invention also provides a material additive method based on the above material additive equipment. The present invention solves the existing problems of difficult preparation of metal powder, high price, and low energy efficiency of laser light sources.

Owner:美光(江苏)三维科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com