High-transmittance interface assembly core-shell type all-liquid device, preparation method and mechanical property regulation and control method thereof

A technology with high transmittance and interface, applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, drug combinations, etc., can solve the long-term maintenance of unfavorable droplet structure stability, hydrogel package Problems such as poor permeation and exchange performance of the coating layer and poor swelling resistance of the hydrogel can achieve the effect of continuous operation, large-scale production, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

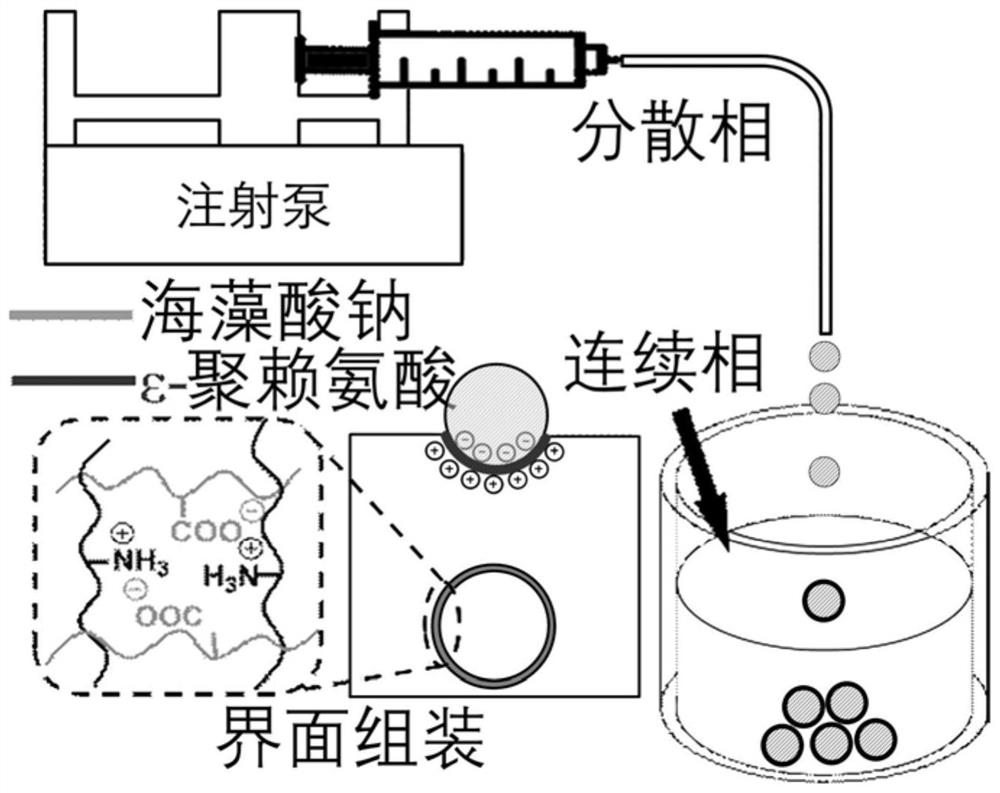

[0047] This embodiment provides a method for preparing an interface-assembled core-shell droplet with high transmittance, which is carried out according to the following specific steps:

[0048] dissolving sodium alginate in water to obtain a sodium alginate aqueous solution with a concentration of 1.5% as a dispersed phase;

[0049] Dissolving ε-polylysine in water to obtain a 1.0% aqueous solution of ε-polylysine as the continuous phase;

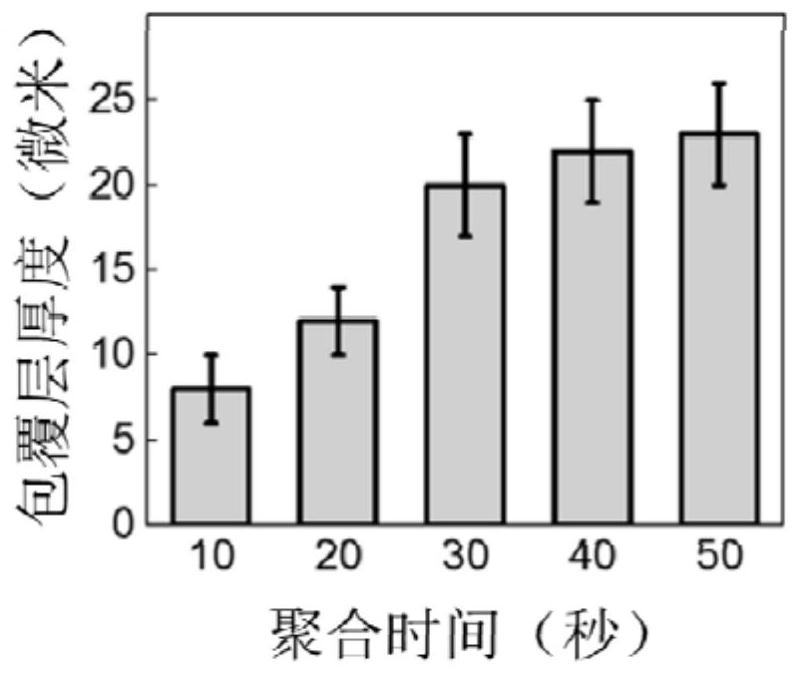

[0050] The dispersed phase was added to the continuous phase in the form of droplets at a constant rate through a syringe pump, and the core-shell droplets were obtained through the interfacial assembly of sodium alginate and ε-polylysine, denoted as Alg@ε-PL, the interface The assembly temperature is 25°C, and the time is 10-50s;

[0051] The Alg@ε-PL was taken out and washed with distilled water to obtain core-shell droplets.

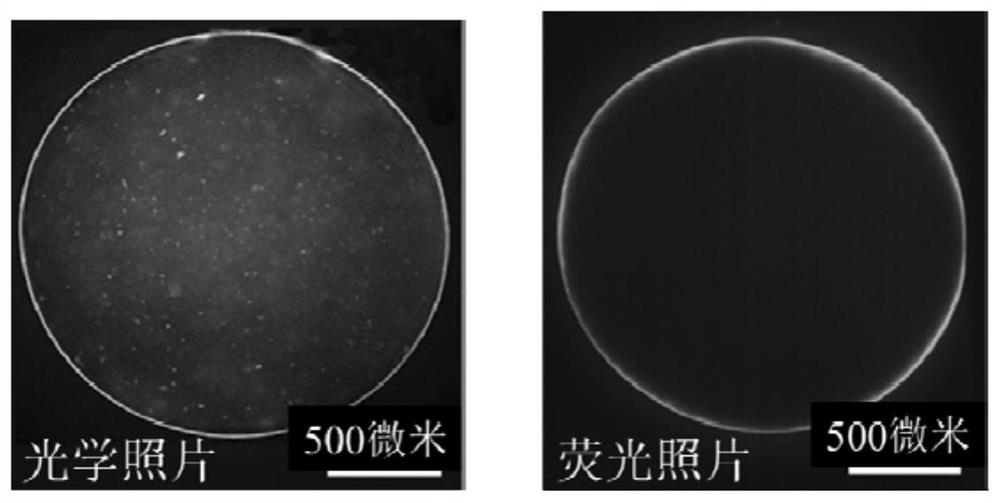

[0052] figure 2 This is the optical image of the core-shell droplet and the fluorescent staining of the cla...

Embodiment 2

[0056] This example provides a method for preparing an interface-assembled core-shell droplet with high transmittance, which is carried out according to the following specific steps:

[0057] dissolving sodium alginate in water to obtain a 2% sodium alginate aqueous solution as a dispersed phase;

[0058] Dissolving ε-polylysine in water to obtain a 1.0% aqueous solution of ε-polylysine as the continuous phase;

[0059] The dispersed phase was added to the continuous phase in the form of droplets at a constant rate through a syringe pump, and the core-shell droplets were obtained through the interfacial assembly of sodium alginate and ε-polylysine, denoted as Alg@ε-PL, the interface The assembly temperature is 25°C, and the time is 20s, 30s and 40s respectively;

[0060] The Alg@ε-PL was taken out and washed with distilled water to obtain core-shell droplets.

[0061] Figure 4 It is a schematic diagram of visible light transmission of core-shell droplets prepared in Exampl...

Embodiment 3

[0063] This example provides a method for preparing an interface-assembled core-shell droplet with high transmittance, which is carried out according to the following specific steps:

[0064] Sodium alginate is dissolved in water to obtain sodium alginate aqueous solutions with concentrations of 2% and 3%, respectively, as the dispersed phase;

[0065] Dissolving ε-polylysine in water to obtain a 1.0% aqueous solution of ε-polylysine as the continuous phase;

[0066] The dispersed phase was added to the continuous phase in the form of droplets at a constant rate through a syringe pump, and the core-shell droplets were obtained through the interfacial assembly of sodium alginate and ε-polylysine, denoted as Alg@ε-PL, The temperature of the interface assembly is 25°C, and the time is 10s-50s;

[0067] The Alg@ε-PL was taken out and washed with distilled water to obtain core-shell droplets.

[0068] Figure 5 The change diagram of the visible light transmittance with time at d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com