Rolling mill for adjusting pressure compensation deflection

A technology for adjusting pressure and rolling mill, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc. It can solve the problem of different thickness universality, difficult to accurately calculate and process the shape curve of the roll, and rolling force. Different problems, to achieve the effect of reducing the maximum bending deformation deflection, widening the material range, and uniform thickness of rolled steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in detail with reference to the drawings and specific embodiments.

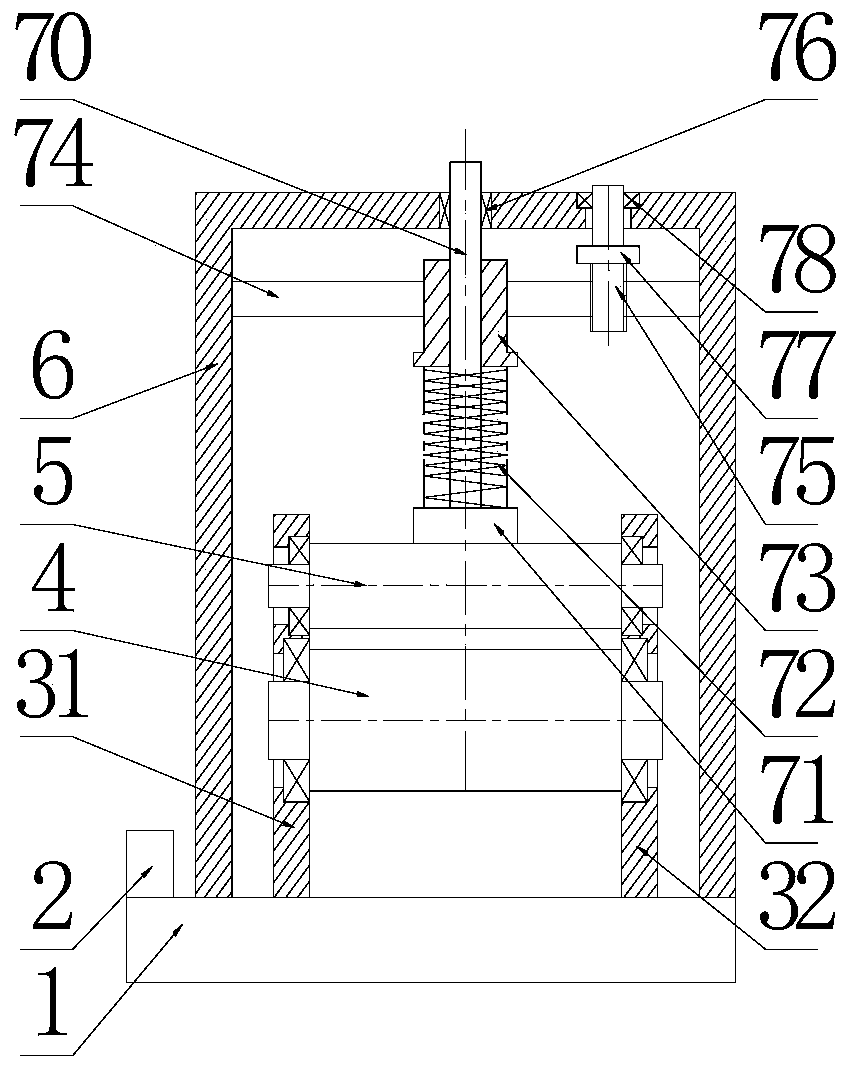

[0021] See figure 1 , figure 2 As shown, a rolling mill for adjusting pressure compensation deflection of the present invention includes: stand 1, roll chock A31 and roll chock B32, both ends of which are respectively installed on the roll chock A31 and the roll chock through the bearings B32, the lower roll 4 and the upper roll 5 installed parallel to each other, and the control system 2, wherein the control system 2 controls the rotation and direction of the two rolls.

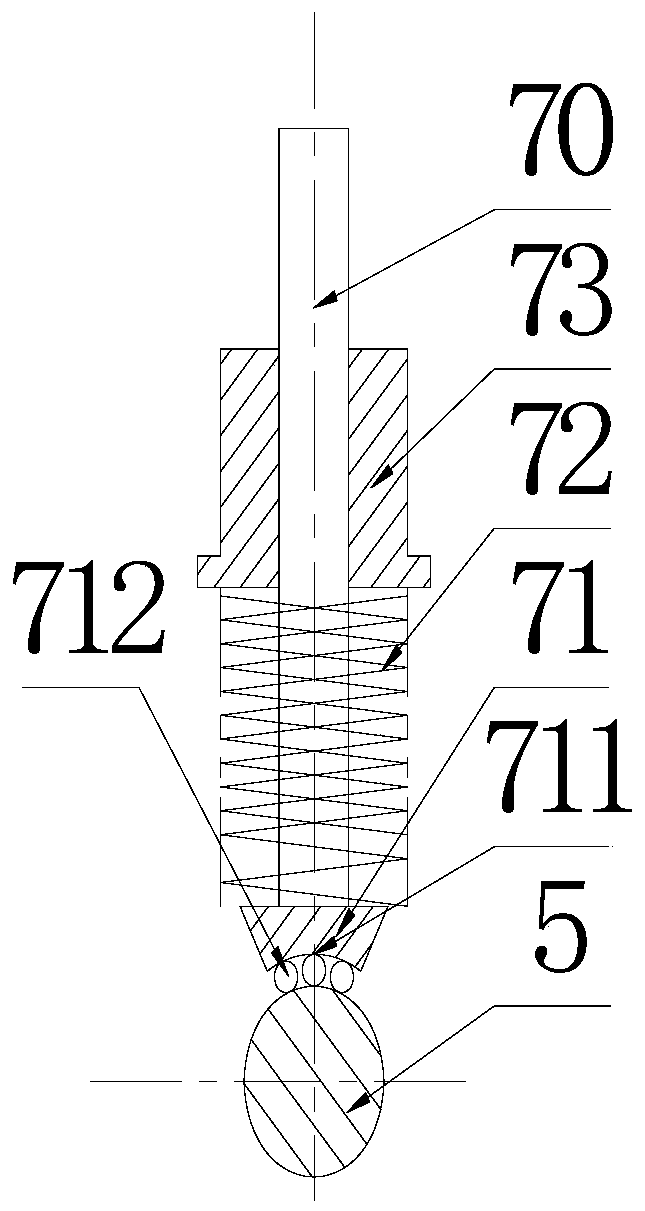

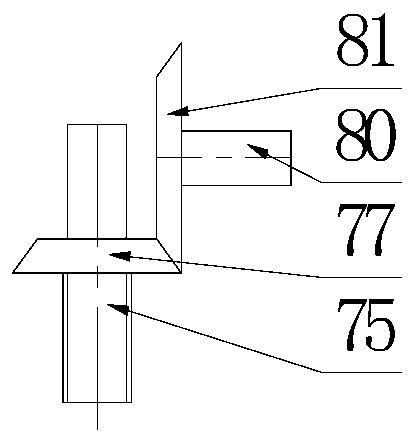

[0022] A rolling mill for adjusting the deflection of pressure compensation further includes a pressure adjusting device. The pressure adjusting device includes: a compensation pressure plate 71 having an arc-shaped contact surface 711 corresponding to the middle of the upper roll 5, and a lifting rod 70 fixedly installed on the compensation pressure plate 71 , The spring press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com