3D printing device and method free of supporting liquid phase mixed materials

A hybrid material, 3D printing technology, applied in the field of 3D printing, can solve the problems of inability to form flexible materials and difficult to remove supporting materials, and achieve the effect of saving printing time, novel structure, and saving printing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

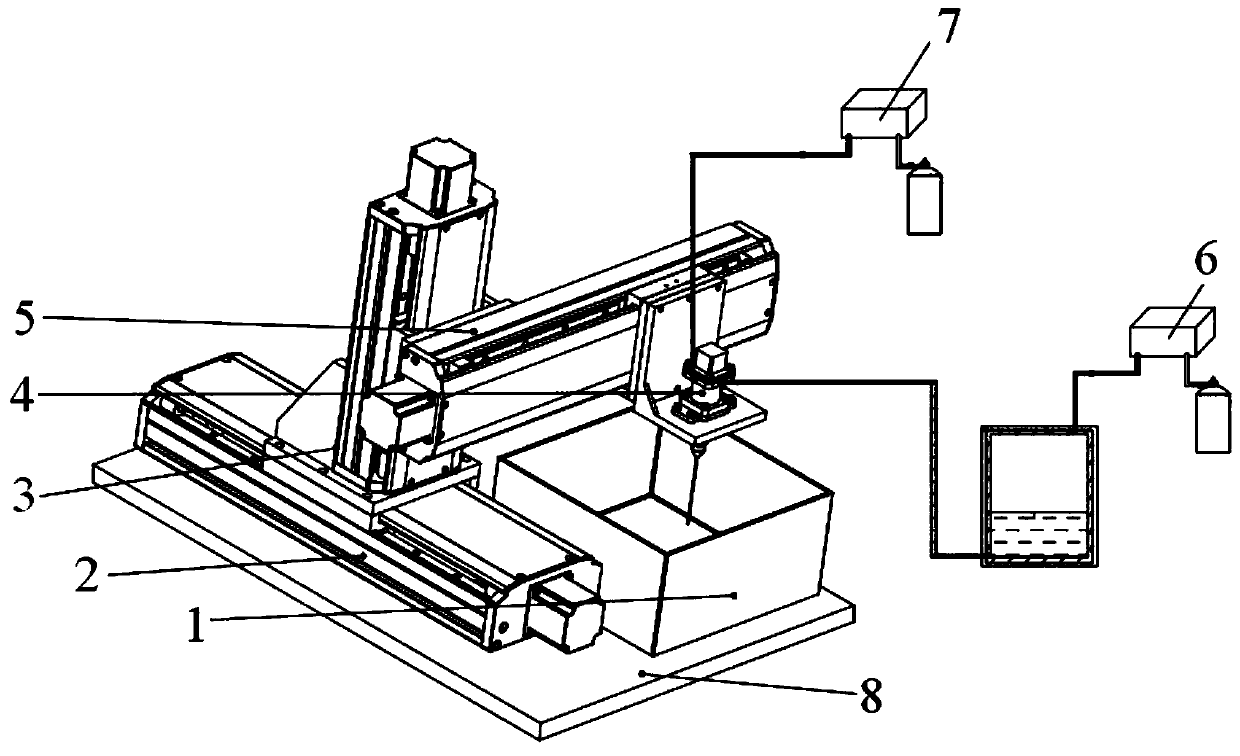

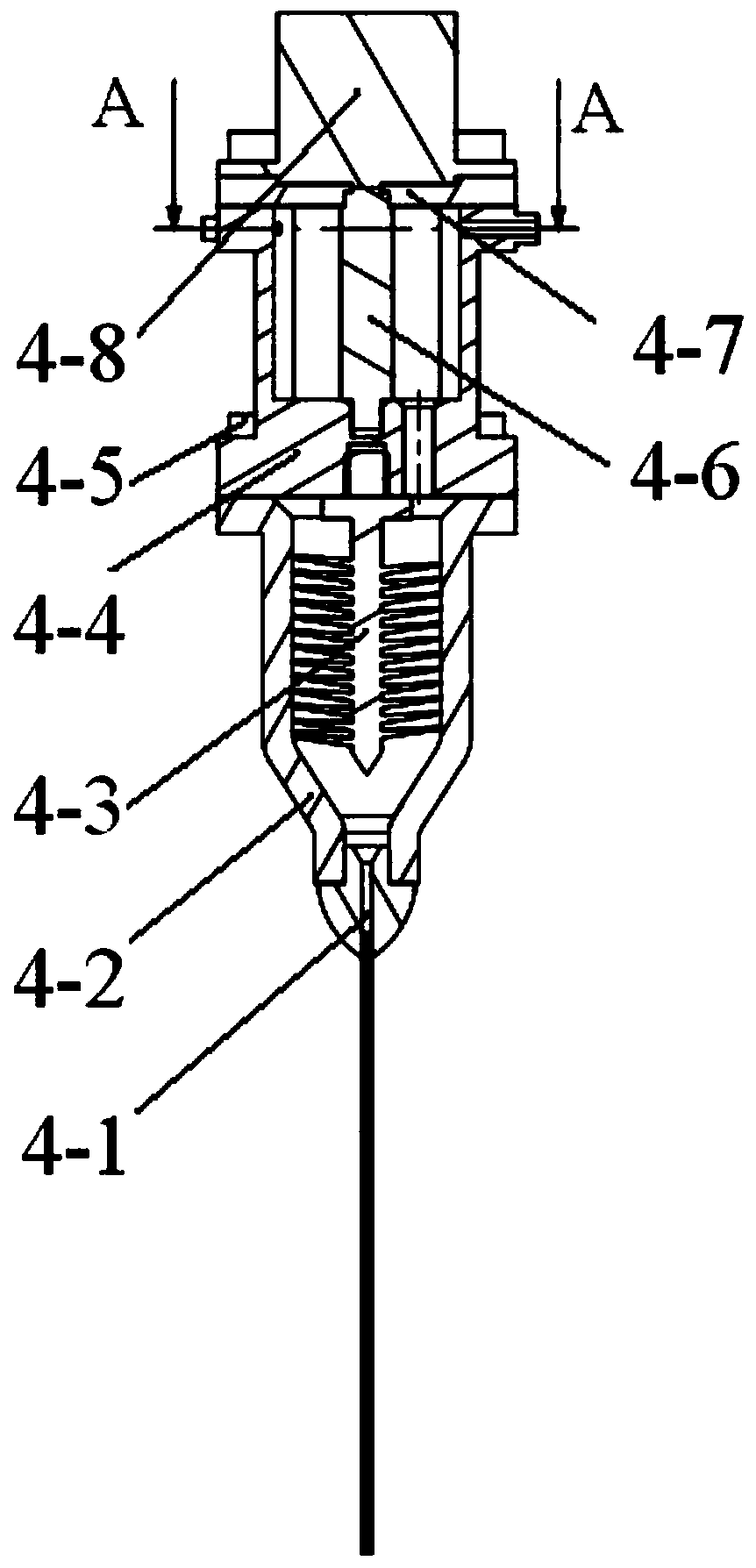

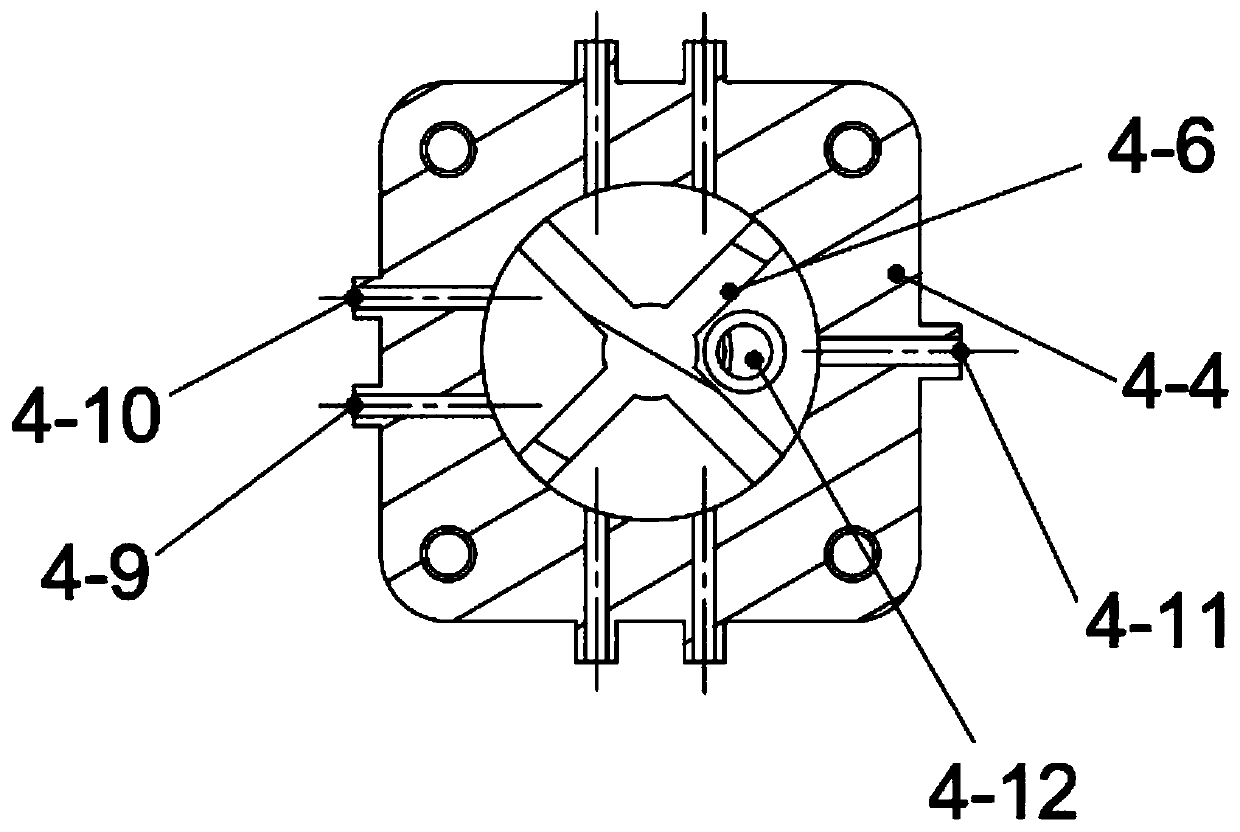

[0029] The container 1 used to store the gel is fixed on the base 8, the Y-axis motion drive 2 is fixed on the base 8, the Z-axis motion drive 3 is connected to the slider of the Y-axis motion drive 2 through screws, and the X-axis motion drive 5 passes through The screw is connected to the slider of the Z-axis motion driver 3, and the print nozzle 4 is connected to the slider of the X-axis motion driver 5 through the connecting block and the screw, and the X, Y, and Z-axis motion drives are used to drive the print nozzle 4 in three-dimensional space During the movement, the three feeding ports 4-9 of the printing nozzle are respectively connected to three sets of feeding systems 6 through conduits, and the air inlets 4-11 are connected to the gas supply system 7 through conduits to provide liquid raw materials 6 for the printing nozzle 4 -2 and the required air pressure for printing, so that the raw materials are sprayed into the gel medium in the container 1 after being fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com