Online component-variable photocuring 3D printing device and method

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of unchangeable material ratio, limitation of forming accuracy, and difficulty in forming fast and high-precision parts, and achieve the effect of broadening the range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

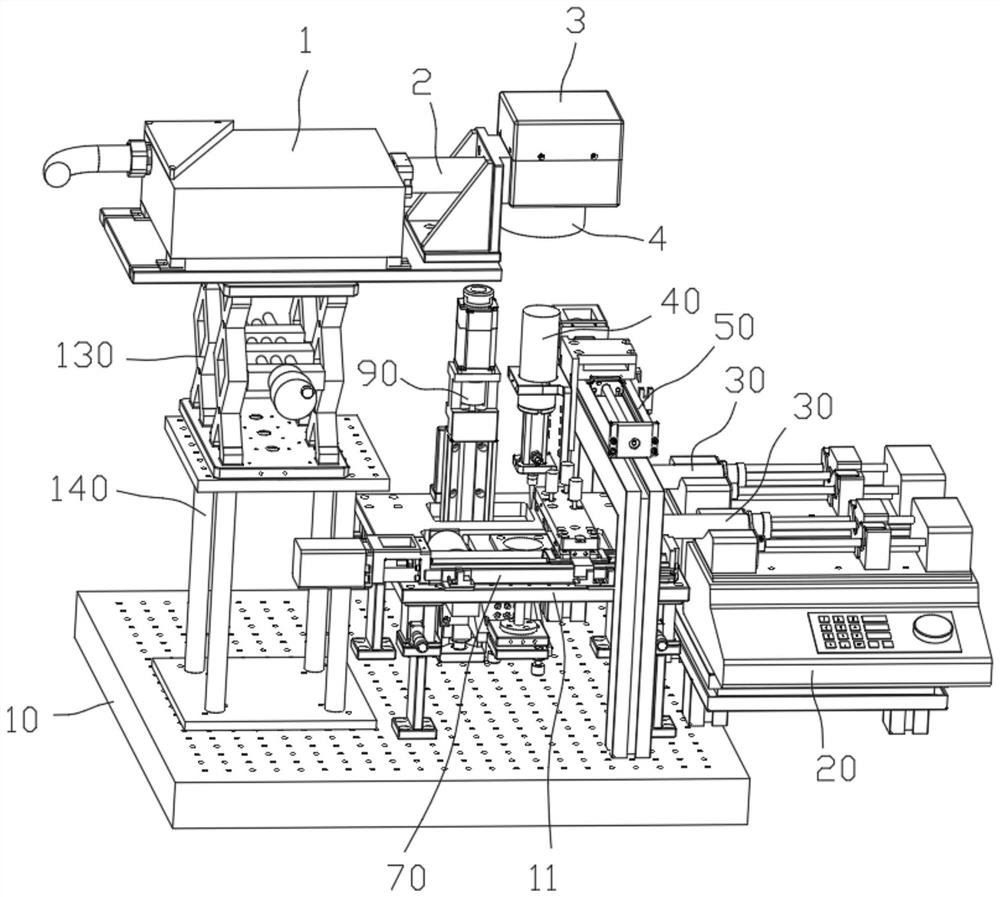

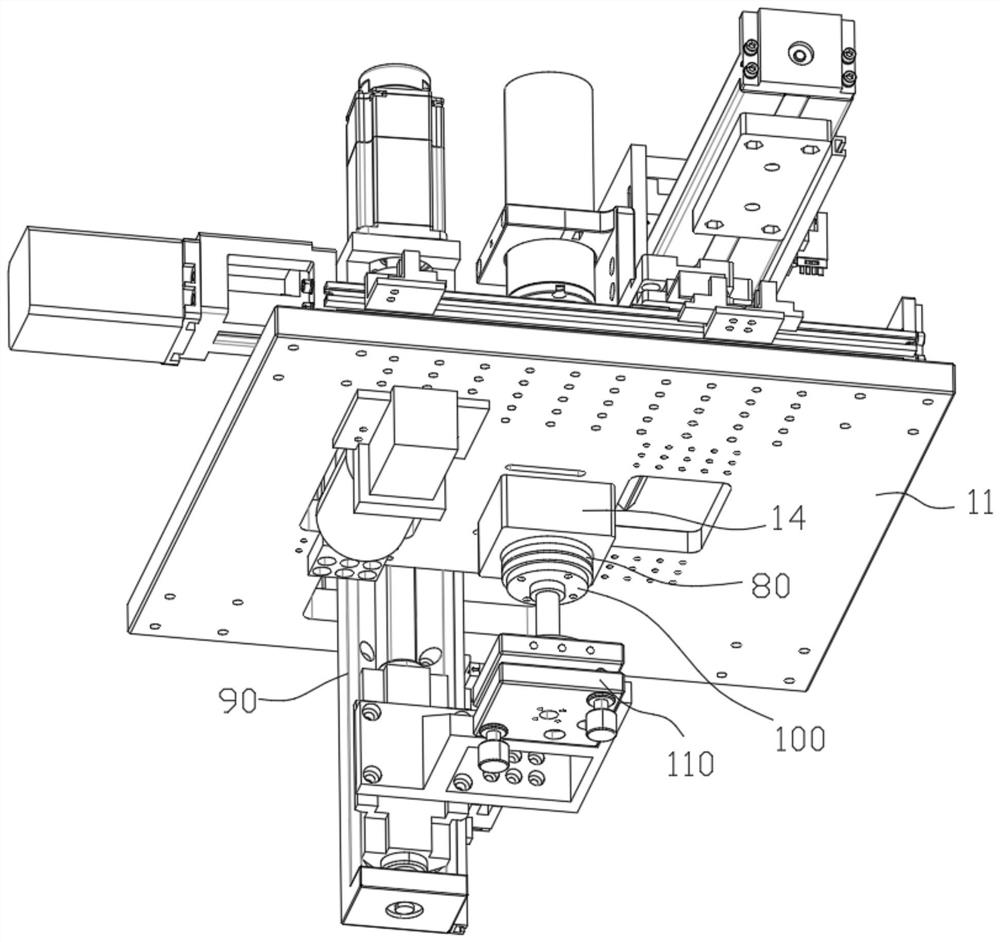

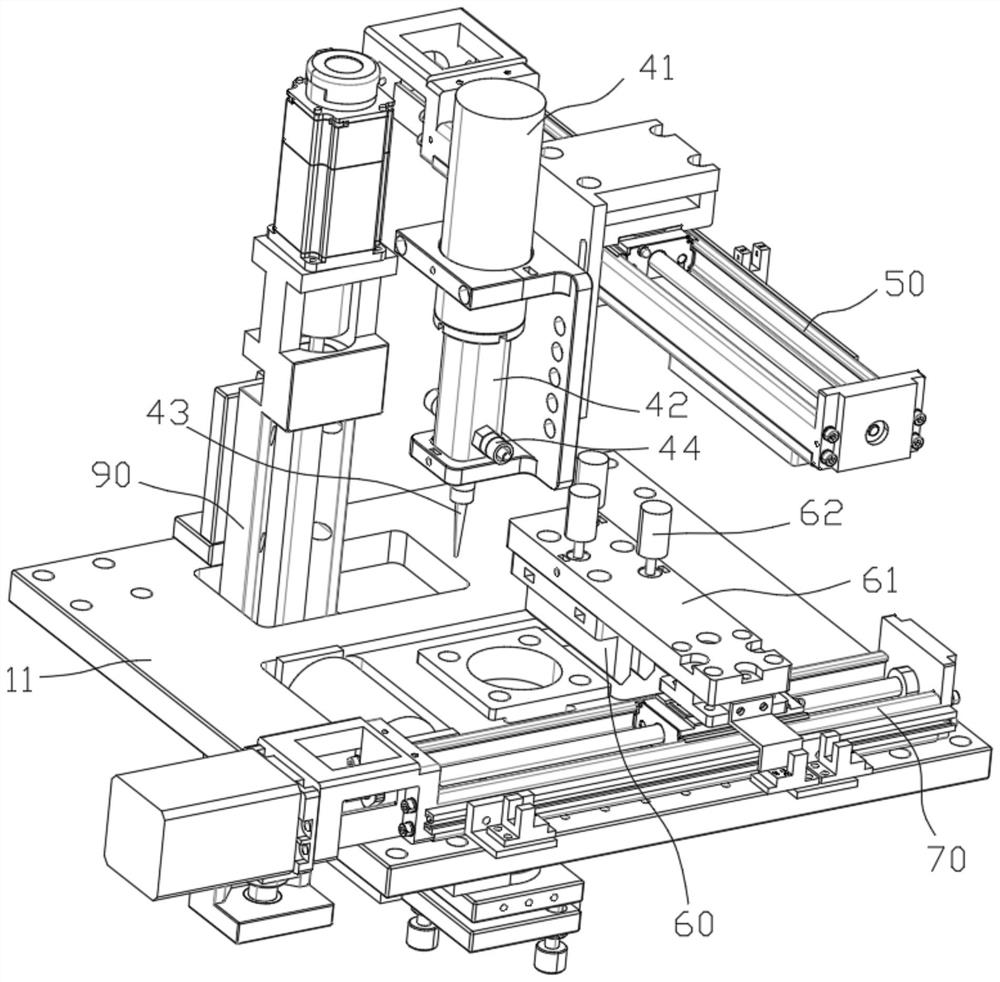

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0036] like Figure 1-4 As shown, the online variable component photocuring 3D printing device of this embodiment includes a base 10 and a laser generating module installed on the base 10, a syringe pump 20, more than two syringes 30, a mixing and feeding mechanism 40, and an X-axis moving mold. group 50, scraper 60, Y-axis moving module 70, printing platform 80 and Z-axis moving module 90, the syringe pump 20 drives the syringe 30 to realize material delivery, and the outlet of the syringe 30 is mixed through the tube body and the mixing and feeding mechanism 40. The material cavity is connected, the X-axis moving module 50 drives the mixing and feeding mechanism 40 to move so that the discharge port of the mixing and feeding mechanism 40 moves to the top of the printing platform 80, and the Y-axis moving module 70 drives the scraper 60 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com