Method for measuring dielectric constant of large loss material

A dielectric constant and digital measurement technology, applied in the direction of measuring electrical variables, measuring resistance/reactance/impedance, measuring devices, etc., to achieve the effect of ensuring consistency, eliminating measurement errors, and fast and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

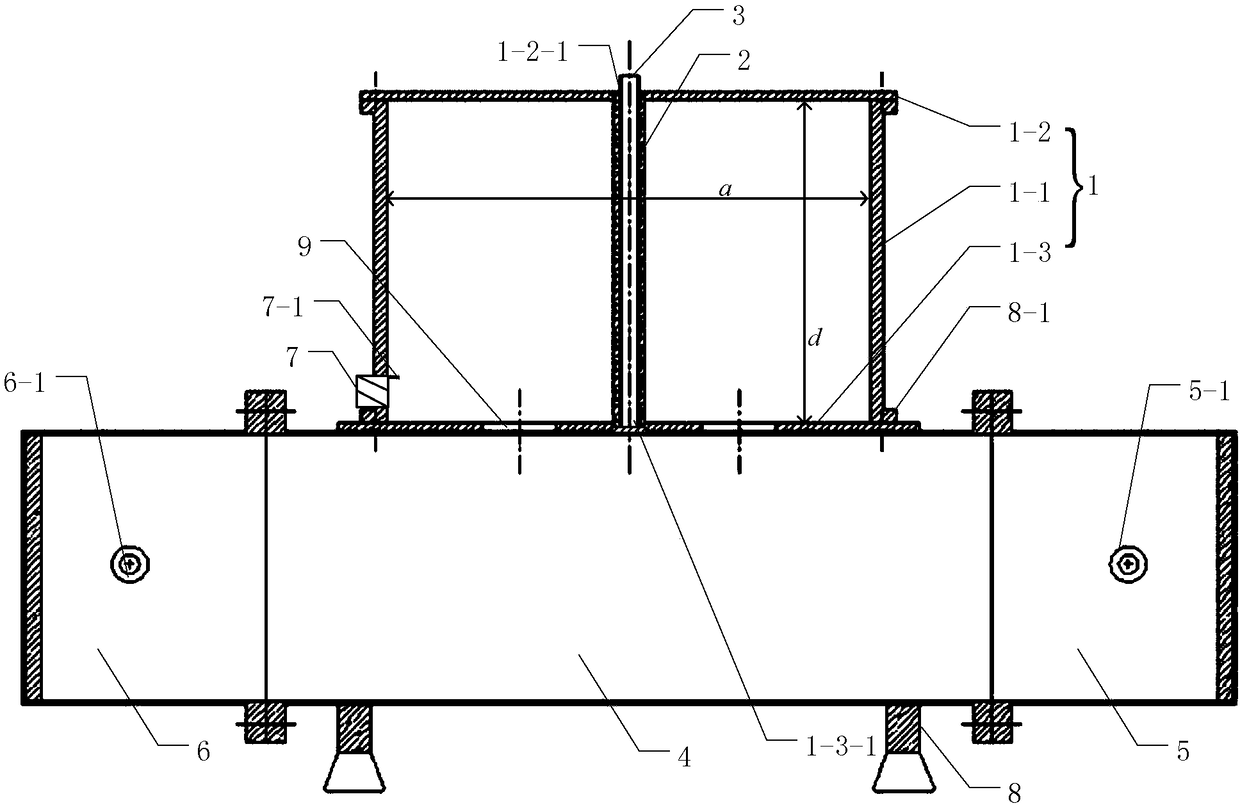

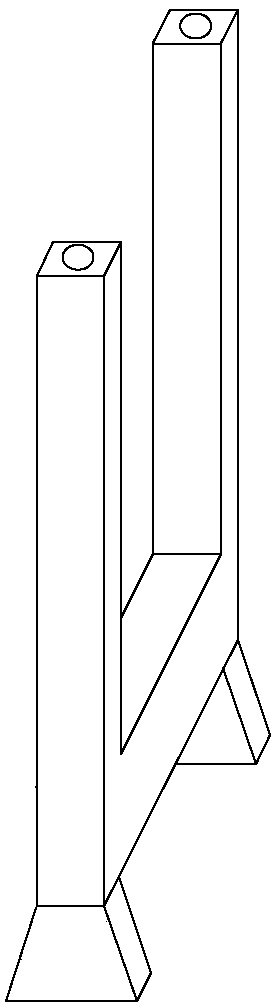

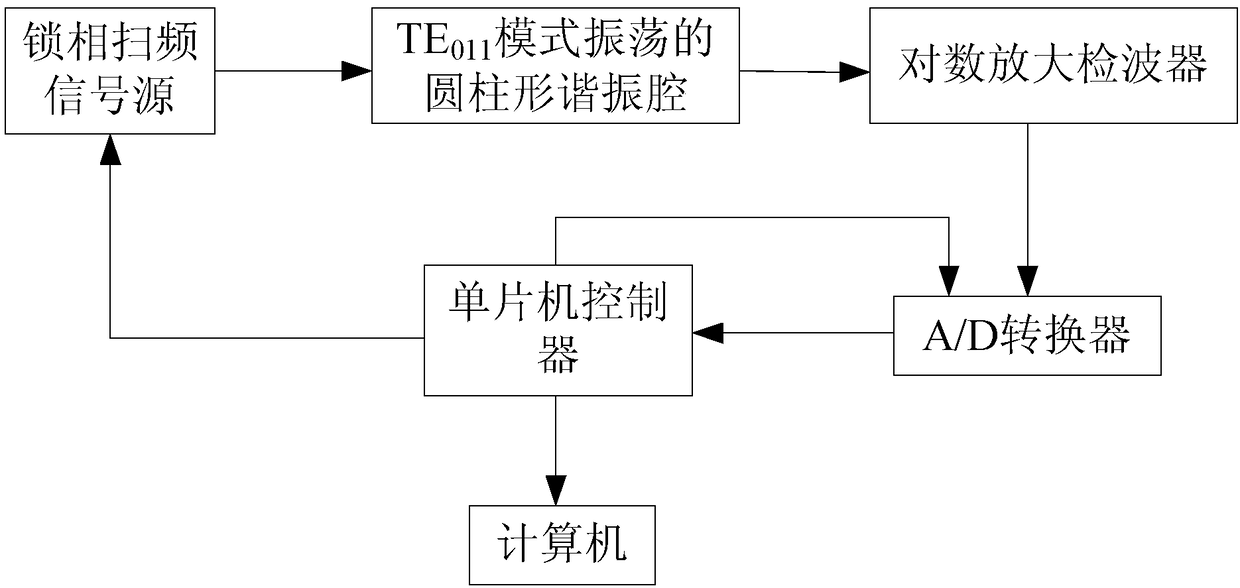

[0039] Specific implementation mode one: combine figure 1 and figure 2 Specifically explain this embodiment, a method for measuring the dielectric constant of a large loss material described in this embodiment, the method is implemented based on a resonant cavity system, the resonant cavity system includes a TE 011 Mode oscillation cylindrical resonator 1, quartz tube sleeve 2, quartz tube 3, excitation rectangular straight waveguide 4, terminal waveguide load 5, input waveguide coaxial converter 6, output SMA flange 7 and fixing bracket 8;

[0040] Quartz tube sleeve 2 inserted into TE 011 In the center of the cylindrical resonant cavity 1 that oscillates in the mode, the quartz tube 3 is tightly sleeved in the quartz tube sleeve 2 to excite the narrow wall of the rectangular straight waveguide 4 and the TE 011 The cylindrical resonant cavity 1 that oscillates in the mode is fixedly connected by a fixed bracket 8 and fastened with a screw 8-1 to excite the rectangular stra...

specific Embodiment approach 2

[0060] Specific implementation mode two: combination figure 1 Describe this embodiment in detail. This embodiment is a further description of a method for measuring the dielectric constant of a large loss material described in Embodiment 1. In this embodiment, TE 011 The cylindrical resonant cavity 1 for mode oscillation includes a cavity 1-1, an upper cover 1-2 and a lower cover 1-3, and the cavity 1-1, the upper cover 1-2, and the lower cover 1-3 are all fixed by screws Install.

[0061] TE 011 The design of the upper and lower cover structures of the cylindrical resonant cavity of mode oscillation is beneficial to the processing and production of the cavity, and is beneficial to the installation and fixing of the quartz tube sleeve 2 . The plane where the small ring set at the end of the output SMA flange 7 is located is the same as the TE 011 The plane of the upper cover 1-2 and the lower cover 1-3 of the cylindrical resonant cavity 1 that oscillates in the mode is para...

specific Embodiment approach 3

[0064]Specific embodiment three: This embodiment is a further description of a method for measuring the dielectric constant of a large loss material described in specific embodiment two. In this embodiment, the quartz tube sleeve 2 passes through the center of the upper cover 1-2. The through hole 1-2-1 is inserted into the cavity 1-1, the top end of the quartz tube sleeve 2 is fixed in the through hole 1-2-1, and the bottom end of the quartz tube sleeve 2 is embedded in the recess in the center of the lower cover 1-3. Inside slot 1-3-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com