Metal casting and continuous rolling method and equipment capable of achieving melt distribution and heat exchange separation in crystallizer

A melt distribution and crystallizer technology, applied in metal rolling and other directions, can solve problems such as difficult removal of oxide film, achieve the effect of increasing material range, solving surface oxidation, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

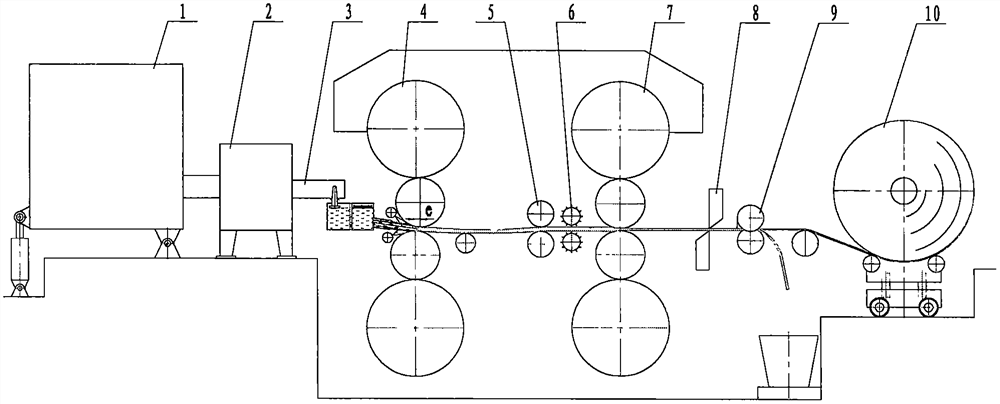

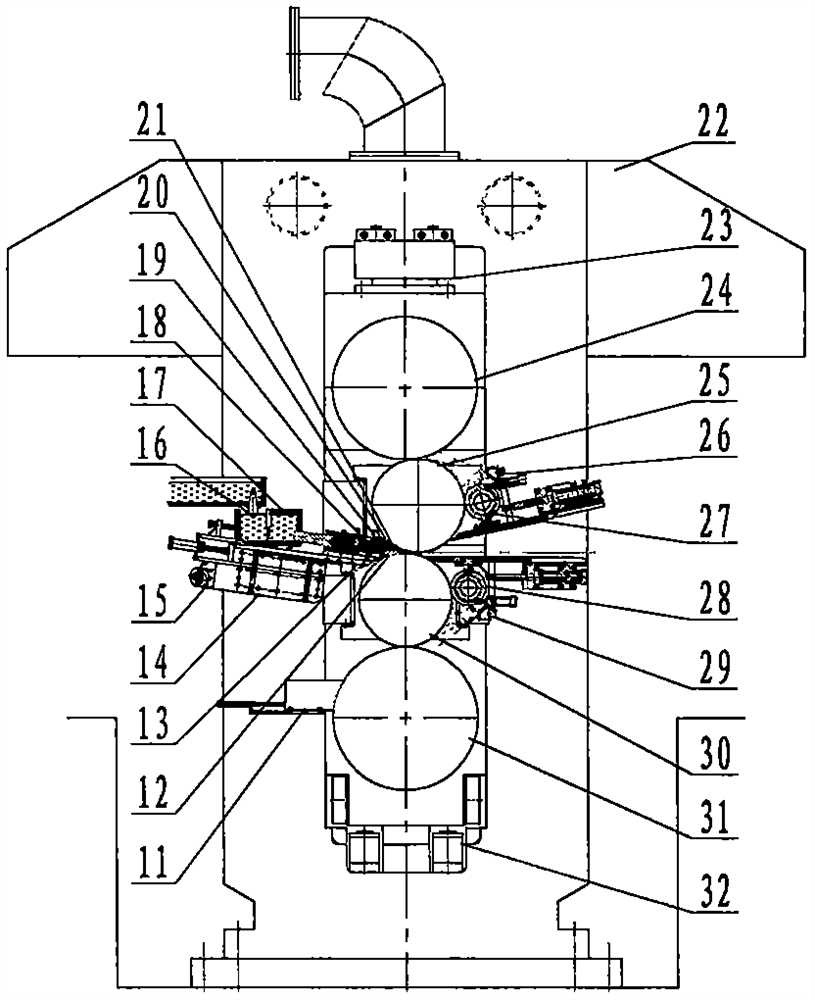

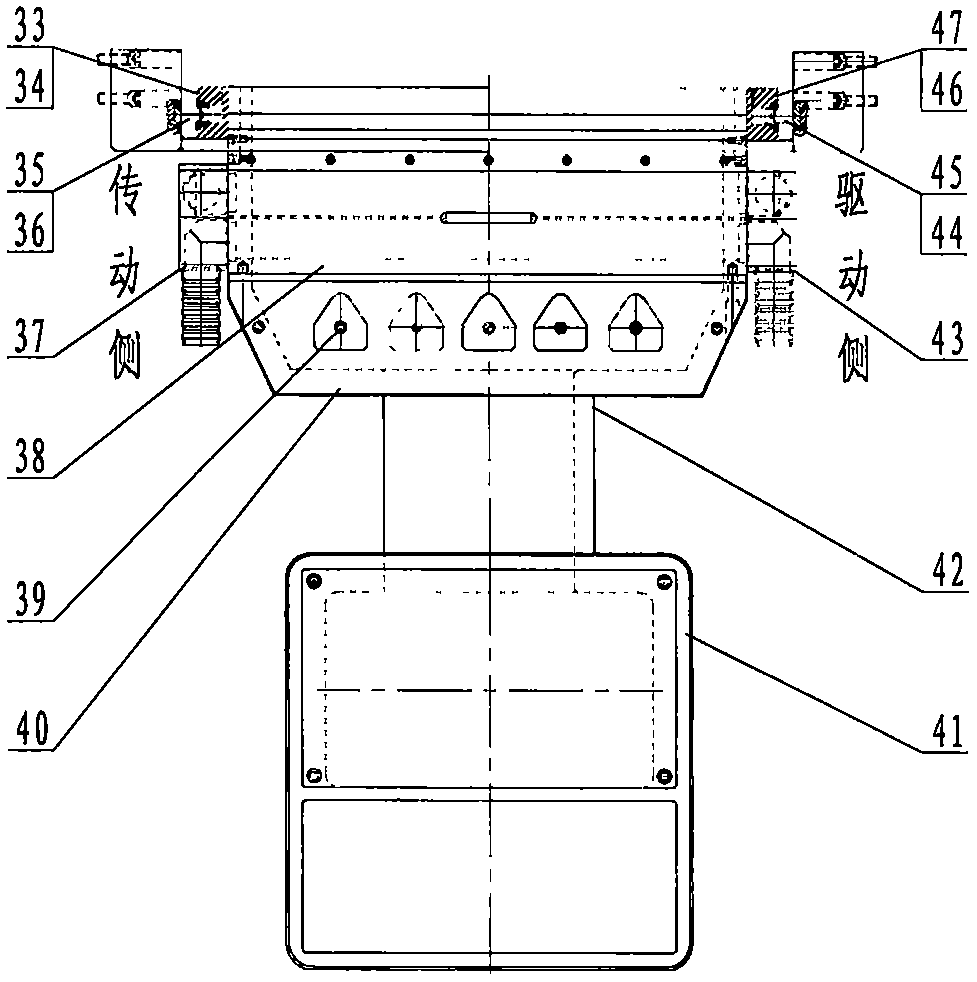

[0040] in the attached figure 1 and 2 In the preferred embodiment shown, take the metal casting and continuous rolling equipment of φ560 / φ980×1820mm specification as an example to produce aluminum alloy slabs, and further illustrate the present invention:

[0041] The thickness of the crystallizer channel is 10mm, casting slabs with a thickness of 8mm, the casting speed is 6-18m / min, the deformation rate of the casting slab is 20-65%, the thickness of the casting and rolling mill exit is 2.8-6.4mm, and the exit speed is 7.2-30m / min.

[0042] Before the vertical plate: the crystallizer is docked with the rolls of the casting and rolling mill, the linear speed of the rolls is set within the range of 6-18m / min, and the gate of the distributor is confirmed to be closed, and the aluminum alloy melt at 680°C-720°C is continuously injected into the front box and Distributor, open the discharge port of the distributor, when the temperature of the melt at the discharge port is close t...

Embodiment 2

[0047] in the attached figure 1 and 2 In the preferred embodiment shown, take the metal casting and continuous rolling equipment of φ540 / φ920×1200mm specification as an example to produce copper alloy slabs, and further illustrate the present invention:

[0048] The thickness of the crystallizer runner is 30mm, casting a slab with a thickness of 25mm, the casting speed is 4-10m / min, the deformation rate of the casting slab is 12-58%, the thickness of the exit of the casting and rolling mill is 10-22mm, and the exit speed is 4.5-16m / min.

[0049] Before the vertical plate: the crystallizer is docked with the rolls of the casting and rolling mill, the linear speed of the rolls is set within the range of 4 to 10m / min, and the gate of the distributor is confirmed to be closed, and the copper alloy melt at 1100°C to 1160°C is continuously injected into the front box and Distributor, open the discharge port of the distributor, when the temperature of the melt at the discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com