Catalyst used for preparing low-carbon olefin from synthetic gas and application of catalyst

A technology of low-carbon olefins and catalysts, applied in the field of catalysts for producing low-carbon olefins from synthesis gas, can solve the problems of reduced number of effective active sites, low selectivity of low-carbon olefins, small particle size dispersion, etc., and achieve a simple and easy preparation method control, high conversion rate and low carbon olefin selectivity, and the effect of oxygen-containing group improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

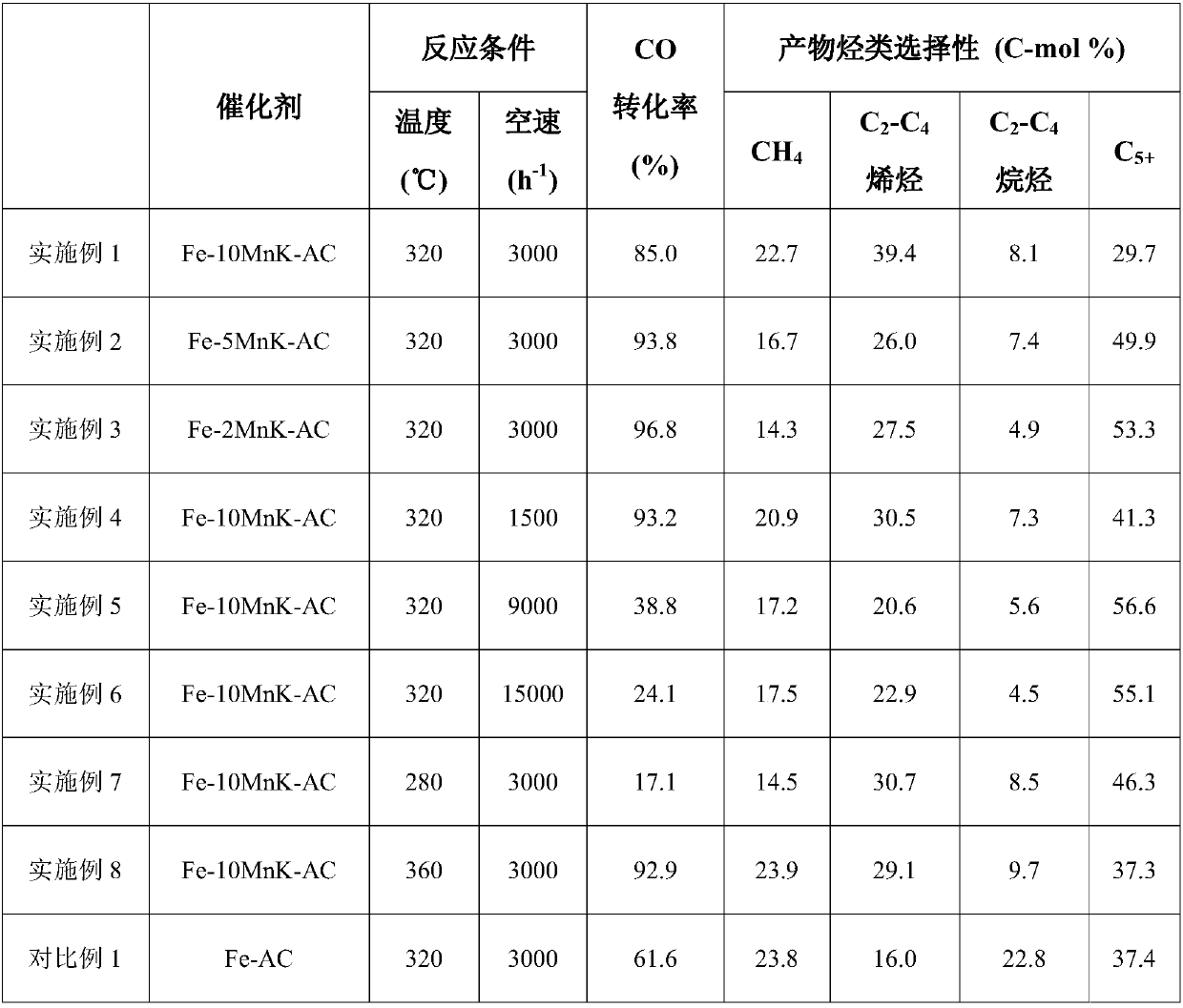

Embodiment 1

[0027] Include the following steps:

[0028] 1. Boil an appropriate amount of activated carbon with deionized water and wash it with water to remove ash and impurities in the activated carbon, then disperse it in a 10wt% nitric acid solution, reflux it in an oil bath at 80°C for 5 hours, and then wash it with deionized water until the filtrate pH=7, to remove residual metal ions in the activated carbon, the filter cake was placed in an oven at 60°C and dried overnight; 3 g of activated carbon washed with water and acid washed were dispersed into an aqueous potassium permanganate solution with a concentration of 0.1 mol / L, Control the mass ratio of potassium permanganate to activated carbon between 0.2-1.1, stir magnetically at 70°C for 30 minutes, then filter and wash with deionized water until the filtrate is colorless, and dry overnight in an oven at 120°C to obtain the pre- Treated activated carbon carrier;

[0029] 2. Prepare an aqueous ferric nitrate solution with a load...

Embodiment 2

[0033] With reference to Example 1, the difference is that the concentration of potassium permanganate aqueous solution in step 1 is 0.05mol / L, and the catalyst obtained is denoted as Fe-5MnK-AC; Others are the same as in Example 1.

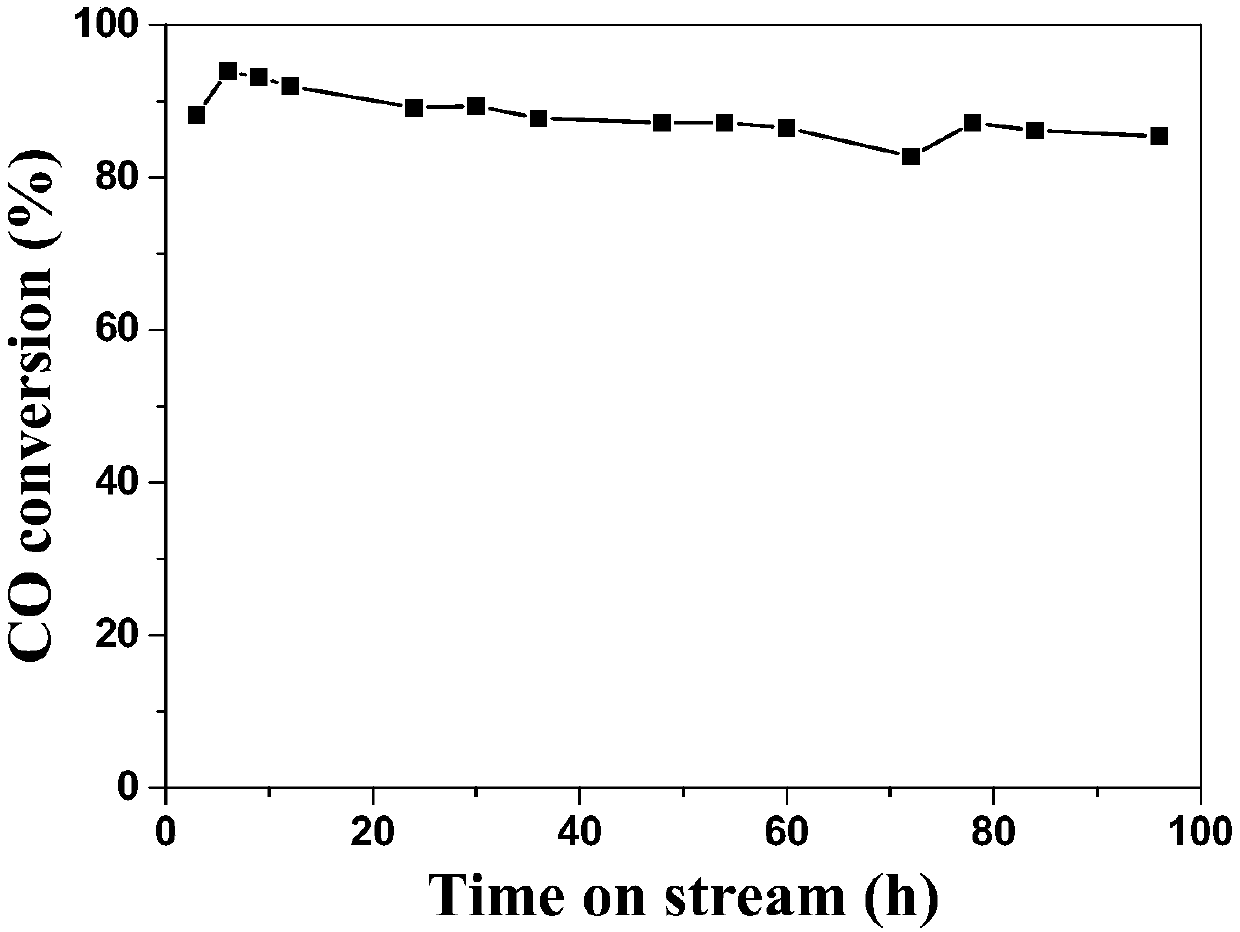

[0034] After the reaction is stable, the gas obtained from the reaction is directly passed into gas chromatography (FID, TCD) to detect and analyze its components on-line, and the liquid components (water phase and oil phase) obtained from the reaction are collected by cold traps connected to the fixed bed , The liquid components were taken out and weighed every 24 hours, wherein the hydrocarbon content in the water phase product was extremely low and negligible, and the oil phase product was analyzed by off-line gas chromatography. The main components of gas-phase hydrocarbon products are alkanes and olefins below C5, and the main components of oil-phase hydrocarbon products are long-chain alkanes and olefins above C5 and their isomers, alcohols ...

Embodiment 3

[0036] With reference to Example 1, the difference is that the concentration of potassium permanganate aqueous solution in step 1 is 0.02mol / L, and the catalyst obtained is denoted as Fe-2MnK-AC; Others are the same as in Example 1.

[0037] After the reaction is stable, the gas obtained from the reaction is directly passed into gas chromatography (FID, TCD) to detect and analyze its components on-line, and the liquid components (water phase and oil phase) obtained from the reaction are collected by cold traps connected to the fixed bed , The liquid components were taken out and weighed every 24 hours, wherein the hydrocarbon content in the water phase product was extremely low and negligible, and the oil phase product was analyzed by off-line gas chromatography. The main components of gas-phase hydrocarbon products are alkanes and olefins below C5, and the main components of oil-phase hydrocarbon products are long-chain alkanes and olefins above C5 and their isomers, alcohols ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com