Automatic cell conveying line

A technology of automatic conveying and battery cells, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing product scrap rate, large labor consumption, occupying space and personnel, etc., and achieves the realization of complete automation of production , continuous and efficient production, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

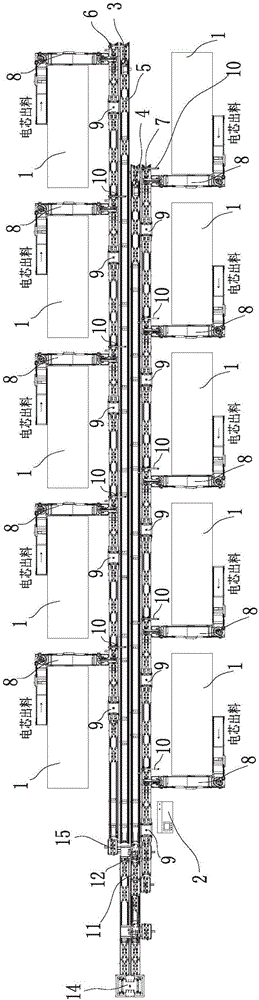

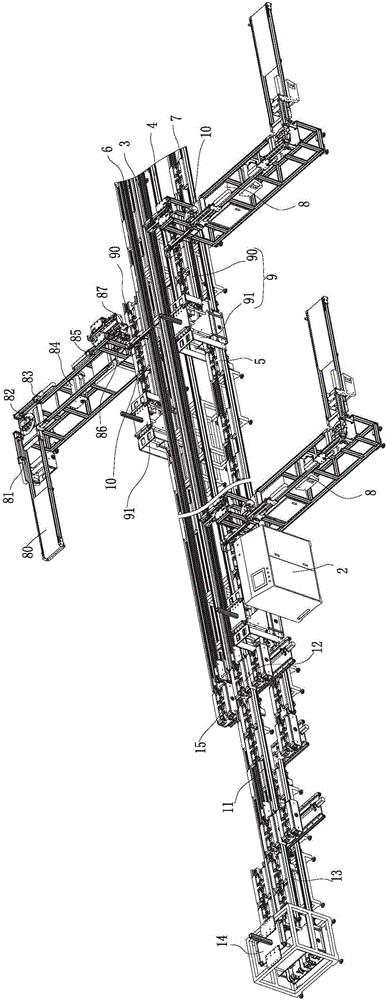

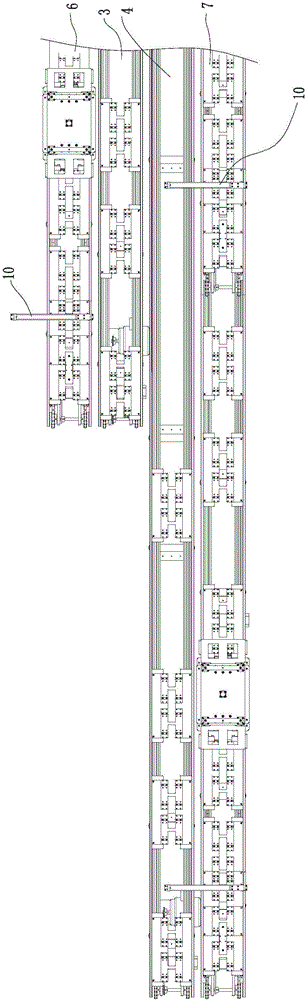

[0033] Battery automatic conveying line, such as Figure 1 to Figure 7 As shown, it is used for the docking of the battery winding machine and the automatic assembly line. The bare battery cores wound by the battery winding machine can be transferred to the automatic assembly line for automatic assembly of batteries through multiple other processes, including multiple A cell winding machine 1 and a main control box 2 also include two rows of first main conveyor belts 3 and second main conveyor belts 4 arranged side by side in the same direction on the top floor of the center, and multiple cell winding machines are facing away from each other. Eccentrically distributed on the outside of the first main conveyor belt 3 and the second main conveyor belt 4 and conveying the wound bare cells to the respective adjacent conveyor belts, on the first main conveyor belt 3 and the second main conveyor belt 4 The carrier box 5 for carrying and transporting each bare cell is respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com