Turnover device for diode package

A flipping device, diode technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving production efficiency, ensuring production quality, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

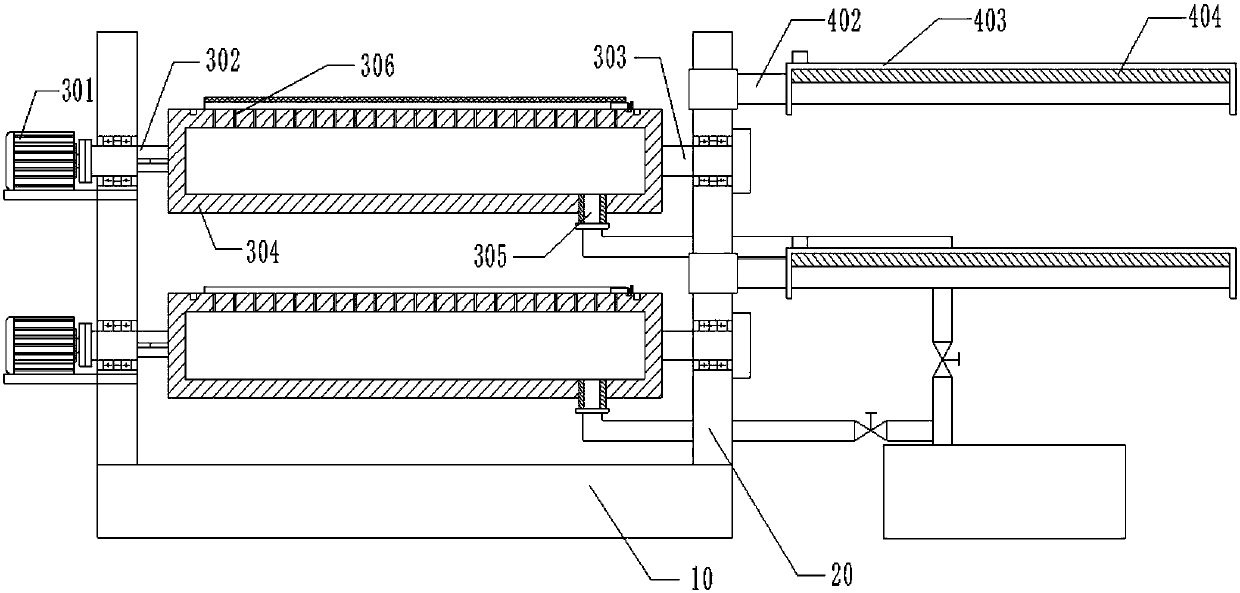

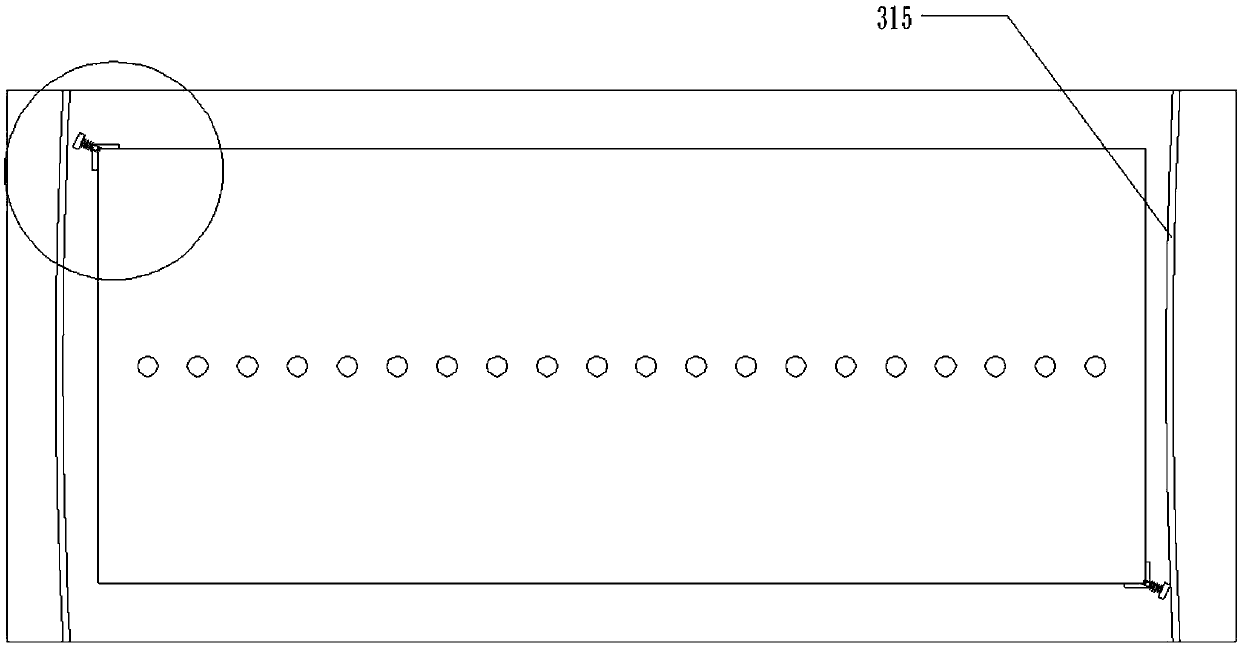

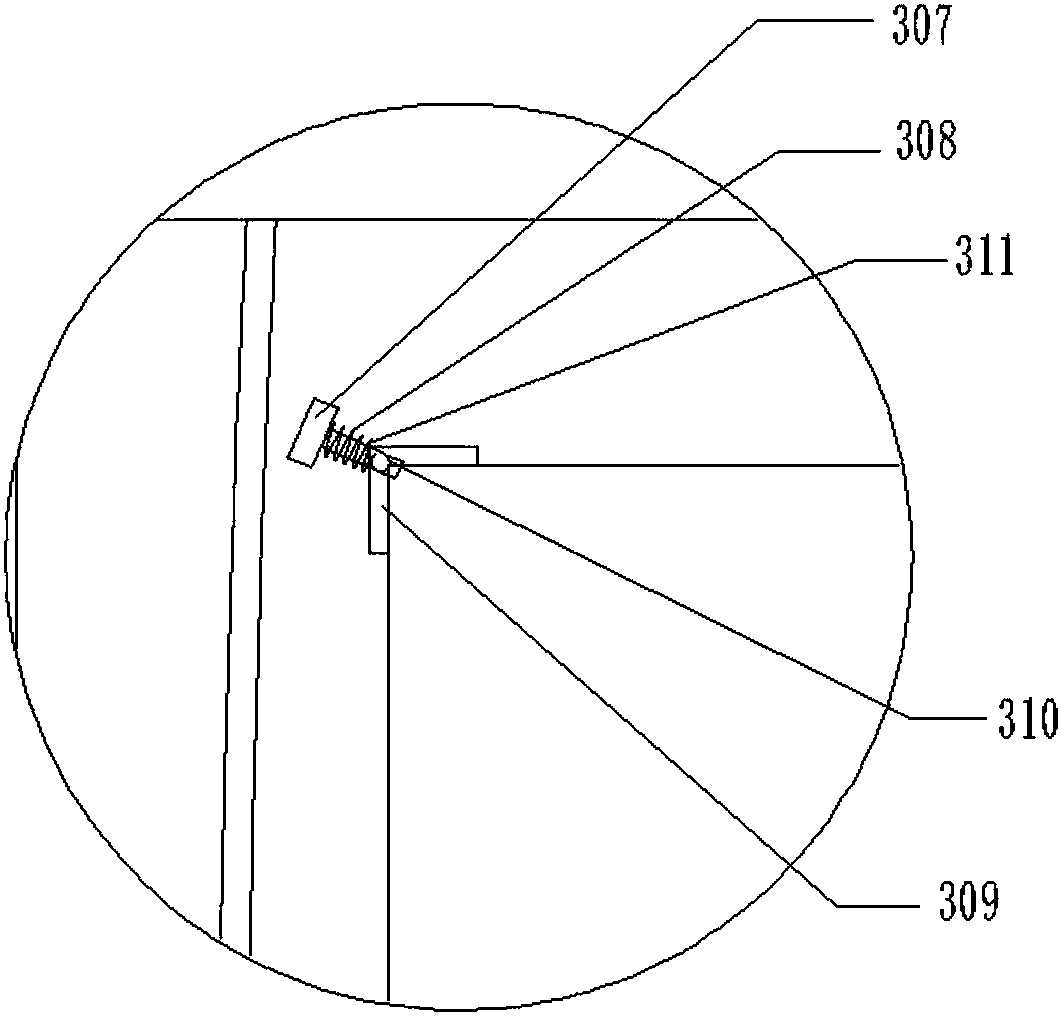

[0033] Such as Figure 1-Figure 8As shown, a flipping device for diode packaging includes a base 10, a column 20, a packaging process 1 30, a baking mechanism 40, a packaging process 2 50, and a baking mechanism 2 60, and the base 10 is vertically and correspondingly arranged Two upright columns 20, between the two upright columns 20 are arranged horizontally from top to bottom sequentially a baking mechanism 1 40, a packaging process 1 30, a baking mechanism 2 60 and a packaging process 2 50, and the two ends of the packaging process 1 30 and the packaging process 2 50 Both are installed on the two uprights 20, and the packaging process 1 30 and the packaging process 2 50 can be rotated 180 degrees, and the ends of the baking mechanism 1 40 and the baking mechanism 2 60 are both set on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com