Method for continuously producing 5-amino-1-amyl alcohol

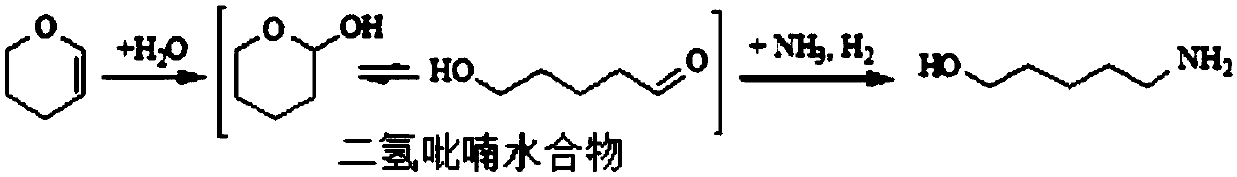

A technology of amyl alcohol and amino group, which is applied in the field of continuous production of 5-amino-1-pentanol, can solve the problems of insufficient cleanliness and high efficiency in the production process, unfavorable large-scale industrial production, low yield of target products, etc., and achieves cheap production raw materials. Easy to obtain, reduce the investment of production equipment and production energy consumption, and have the effect of good life stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of dihydropyran hydrate

[0038] Weigh dihydropyran and deionized water in a mass ratio of 1:2 to 1:9 and add them to a 2L reaction kettle, seal the kettle, and use N 2 After replacement, pressurize to 0.1-3MPa, raise the temperature to 60-140°C under rapid stirring, and react at this temperature for 0.5-20h. After cooling down, collect the reaction solution for later use. Table 1 shows the dihydropyran hydrate prepared under different conditions.

[0039] Table 1. Preparation of dihydropyran hydrate under different conditions and its amination performance

[0040]

[0041]

Embodiment 2

[0042] Embodiment 2: Preparation of supported nickel-based catalyst

[0043]Dissolve a certain amount of nickel salt and metal additive salt in water to make a solution, add the dried carrier, stir into a uniform mud, soak at room temperature for 12 hours, then dry at 110°C for 12 hours, and roast at 500°C for 3 hours. Tablet sieve catalyst particles of 20-40 mesh, fill 2mL (2.4g) in the fixed bed reactor. Finally, in a hydrogen atmosphere (flow rate: 80-100mL / min), the temperature was raised to 450°C and reduced for 4 hours to obtain an activated catalyst. The composition of the catalyst is shown in Table 2.

[0044] Table 2. Catalyst composition and amination performance of dihydropyran hydrate

[0045]

Embodiment 3

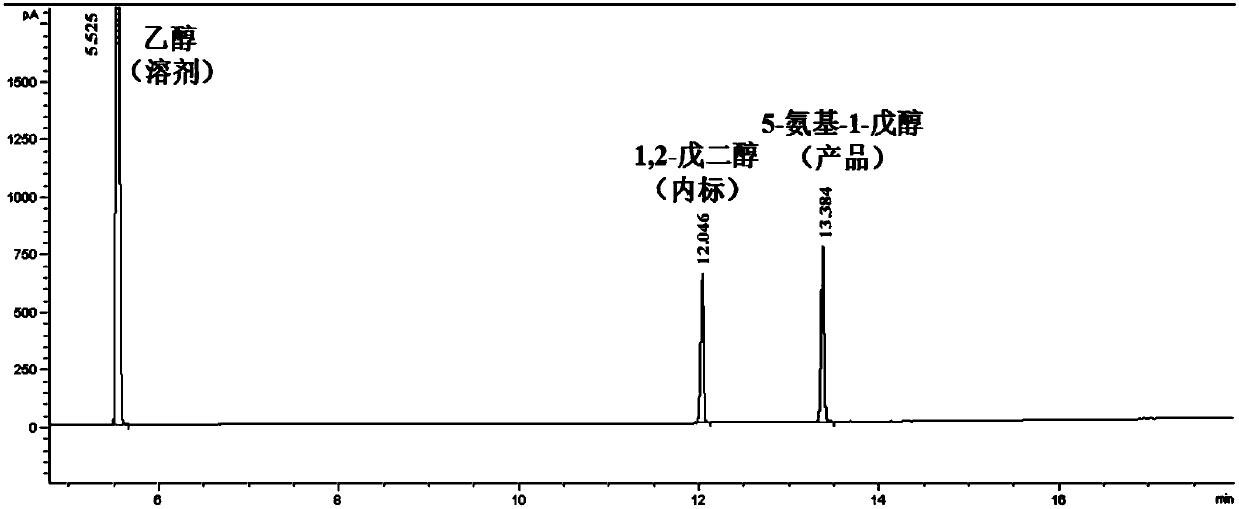

[0046] Example 3: Different catalysts catalyze the amination reaction performance of dihydropyran hydrate and ammonia water

[0047] The dihydropyran hydrate 3 prepared in Example 1 and 25% concentrated ammonia water were mixed evenly in a mass ratio of 1:1 and pumped into the reactor. 2 Pressure 3MPa, H 2 The volume ratio to the reaction liquid is 1200 and the feed volume space velocity is 10h -1 The amination reaction performance of different supported Ni-based catalysts was studied under the same conditions, and the samples after 6h stabilization were taken for gas chromatography analysis. From the results in Table 2, it can be seen that the yield of the target 5-amino-1-pentanol is between 79-93%, indicating that the catalyst synthesized by the present invention can efficiently catalyze the amination reaction of dihydropyran hydrate and ammonia water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com