Carbon-glass one-step hybrid weaving technology and device

A technology, carbon fiber technology, applied in the field of carbon-glass one-step mixed weaving process and equipment, can solve the problems of carbon-glass mixed weaving cloth meter length limit, elongated production process route, increase labor workload, etc., to reduce production costs and Labor cost, continuous and efficient production, and the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

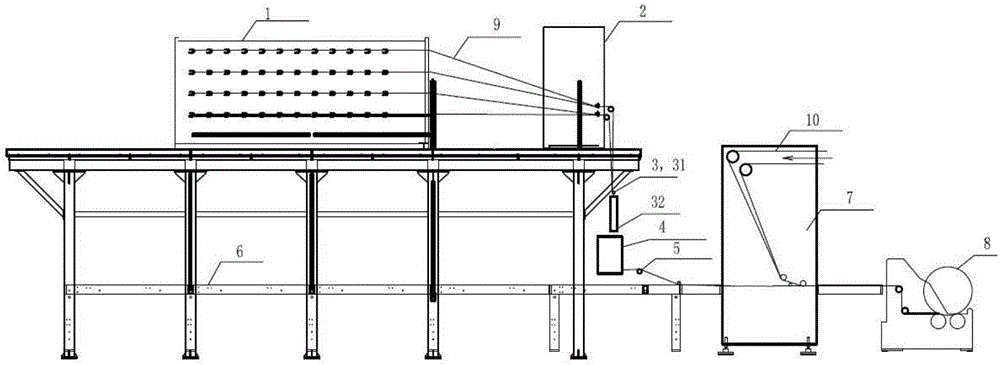

[0020] In view of the defects of the prior art, this embodiment proposes a one-step method to carry out mixed weaving, so the following designs are designed: figure 1 The device system shown includes a constant tension creel 1, a yarn collecting frame 2, a fiber spreading device 3, a rolling roller 31, a vibrating roller 32, a pulling power roller group 4, a tension regulating roller 5 and a PLC control system, which is similar to the original Some weft laying devices 6 and multiaxial warp knitting machine weaving 7 are integrated. The constant tension creel 1 and the creel 2 are set above the weft laying device 6 through the support platform. This embodiment adopts a steel frame platform. The external factors of thread tension are beneficial to control the uniformity of yarn tension. The yarn releasing tension of the constant tension creel 1 is controlled by the PLC control system, and the yarn releasing tension of the constant tension creel 1 is controlled by the PLC system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com