Micro-continuous flow technology for producing tonalide

A technology of musk tona and micro-continuous flow, applied in chemical/physical/physical-chemical processes, organic chemistry, chemical/physical/physical-chemical reactors, etc., can solve the problems of long operation time, high risk and high operation cost , to achieve the effect of reducing raw material loss, easy operation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

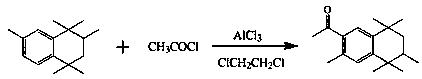

Method used

Image

Examples

Embodiment 1

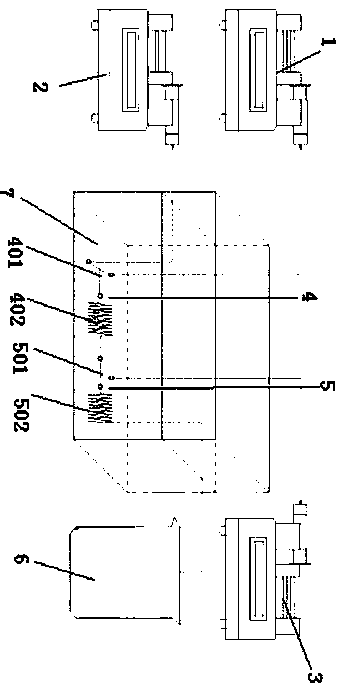

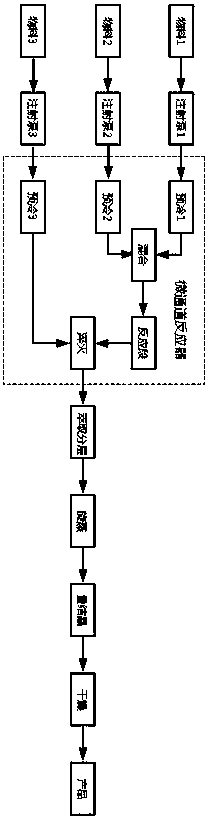

[0035] combined with figure 2As shown, the processing equipment of the present embodiment comprises metering pump a1, metering pump b2 and metering pump c3, and described metering pump a1 links to each other with the first inlet of T-type passage mixer a401 in the microchannel reactor 4, and described metering pump b2 links to each other with the second inlet of the T-shaped channel mixer a401 in the microchannel reactor 4, and the third inlet of the T-shaped channel mixer a401 in the microchannel reactor 4 links to each other with the inlet of the reaction module 402, and the outlet of the reaction module 402 is connected with the microstructure The first inlet of the T-shaped channel mixer b in the mixer 5 is connected, the outlet of the metering pump c3 is connected with the second inlet of the T-shaped channel mixer b, and the third inlet of the T-shaped channel mixer b is connected with the quenching module 502 is connected to the inlet, and the outlet of the quenching m...

Embodiment 2

[0049] This embodiment is consistent with the operation steps of embodiment 1, only acetyl chloride, catalyst AlCl 3 And the molar ratio of dichloroethane was changed to 1:2:5. The conversion rate of HMT and the yield of products were analyzed by GC. In this example, the conversion rate of HMT was 99.5%, the yield of AHMT was 95.3%, and the purity was 98.5%.

Embodiment 3

[0053] This embodiment is consistent with the operation steps of embodiment 1, only acetyl chloride, catalyst AlCl 3 The molar ratio of dichloroethane and dichloroethane was changed to 1:0.5:7. The conversion rate of HMT and the yield of products were analyzed by GC. In this example, the conversion rate of HMT was 99.5%, the yield of AHMT was 93.6%, and the purity was 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com