Dust collecting module and electrostatic air cleaning apparatus

A dust and air technology, applied in electrostatic separation, electrode structure and other directions, can solve the problems of difficult cleaning of metal plates, low efficiency of one-time purification, complicated production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

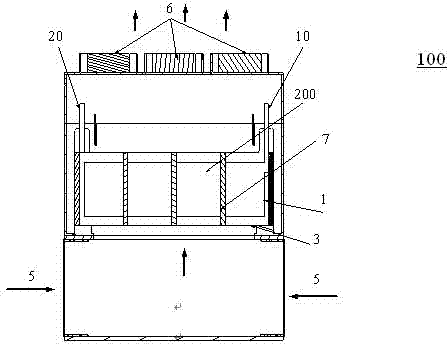

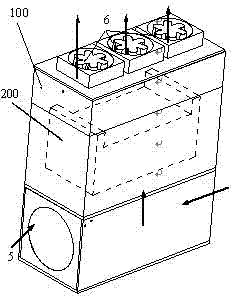

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the dust collection module and the electrostatic air cleaning device provided by the present invention will be described in detail below with reference to the drawings and specific embodiments. In these drawings, the same reference numerals are assigned to the same or corresponding components. The following are only the best implementations of the dust collecting module and the electrostatic air cleaning device of the present invention, and the present invention is not limited to the following structures.

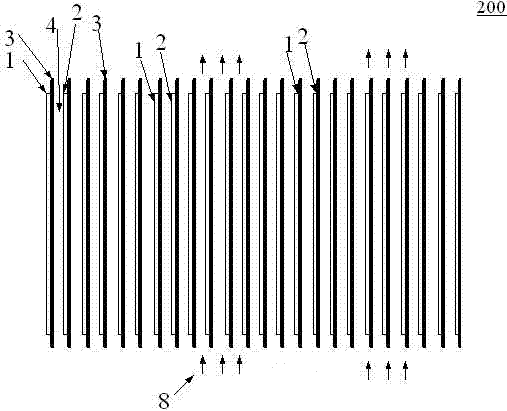

[0022] Such as figure 1 As shown, the dust collection module 200 of this embodiment, the dust collection module 200 includes conductive films and insulating plates, the conductive films and insulating plates are alternately arranged, the insulating plates are separated from the conductive films, and the conductive films adjacent to the insulating plates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com