Raman base

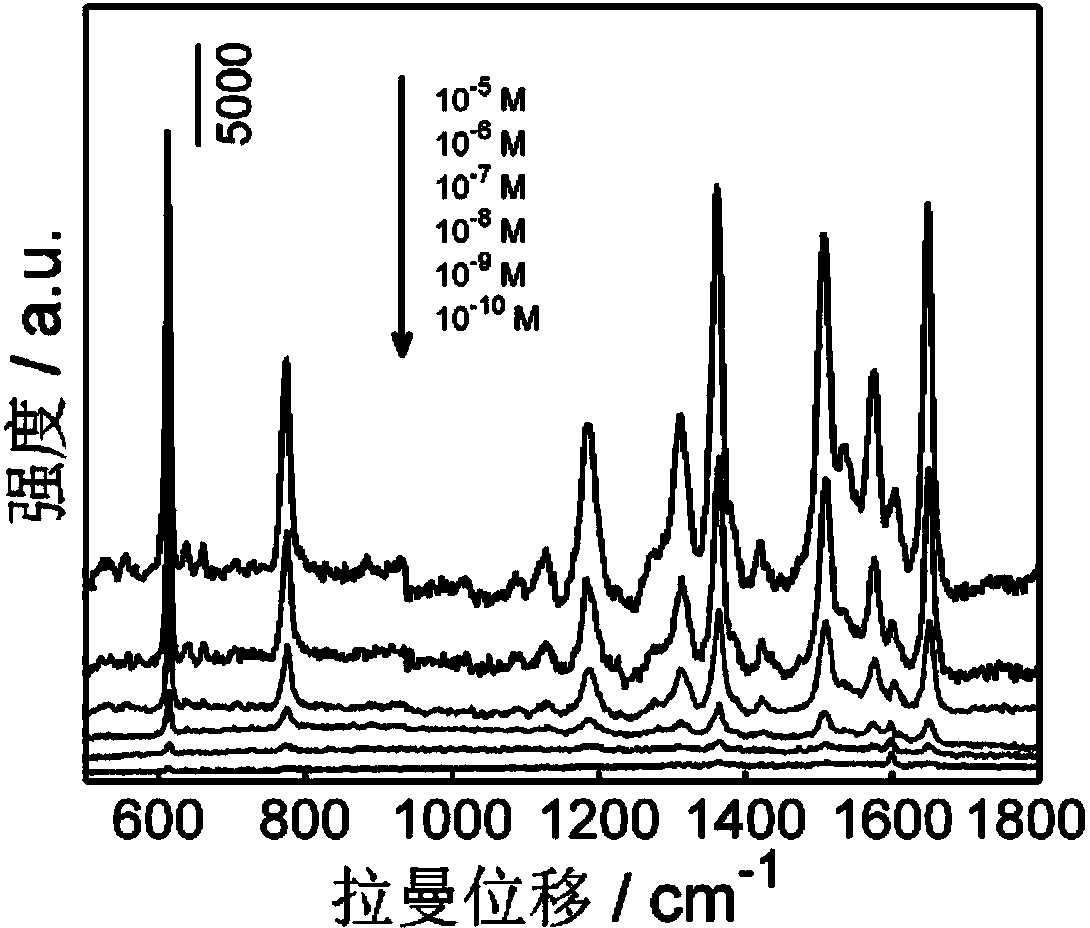

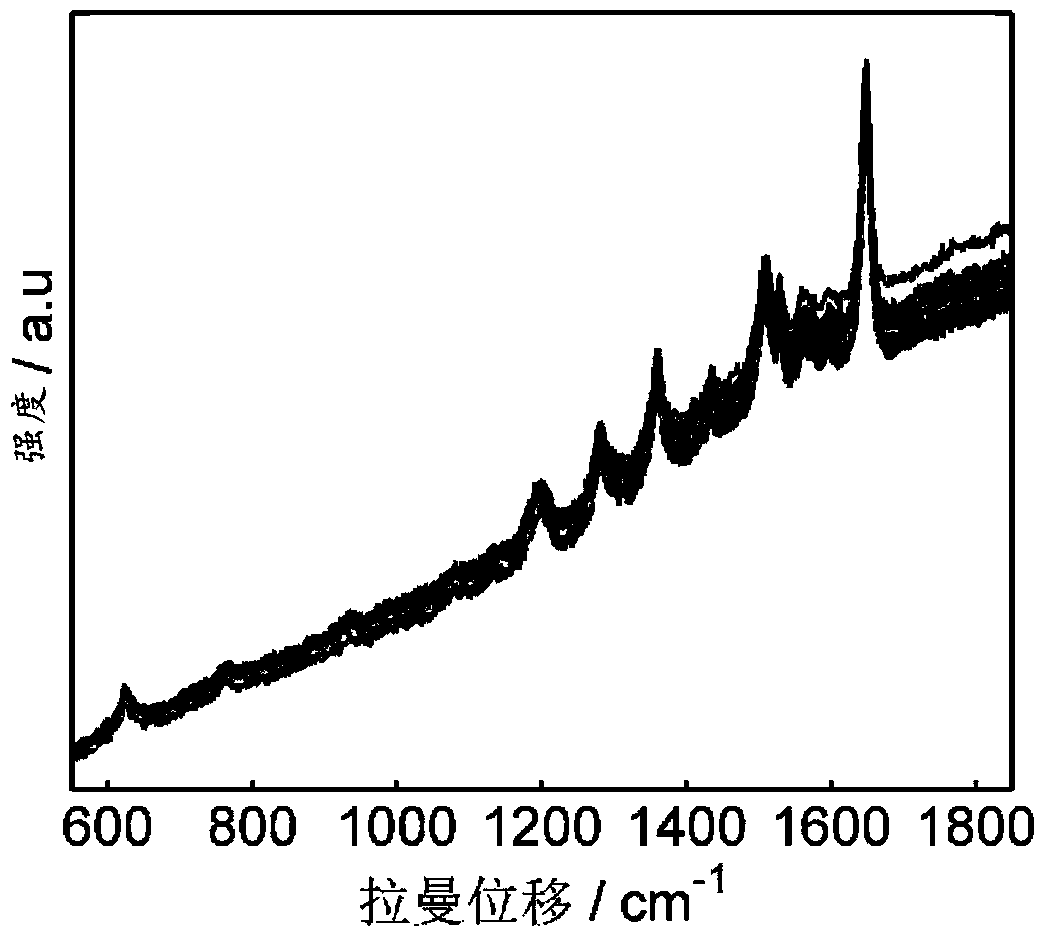

A Raman substrate and substrate technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of poor sensitivity, uniformity and reliability, and achieve good uniformity and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In the present invention, the preparation method of the Raman substrate preferably includes the following steps:

[0050] 1), combining the metal and the Raman base substrate to obtain a metal layer disposed on the Raman base substrate;

[0051] 2), combining the metal layer and the graphene film to obtain a Raman substrate.

[0052] The invention combines the metal and the Raman base substrate to obtain the metal layer arranged on the Raman base substrate. In the present invention, the Raman base substrate and metal layer are consistent with the Raman base substrate and metal layer described in the above technical solution, and will not be repeated here. In the present invention, the metal preferably includes one or more of gold, silver, platinum, copper, aluminum, lithium, sodium, titanium, potassium, nickel, palladium and gallium, more preferably includes gold, silver, copper and One or more of platinum, most preferably one or more of gold, silver and platinum, mos...

Embodiment 1

[0077] by vacuum plasma sputtering in 10 -3 Pa pressure below Depositing a gold film with a thickness of 4 nanometers on a quartz glass substrate at a rate of 100 sccm under the protection of argon gas at a flow rate, the gold film was annealed for 90 minutes in a quartz tube furnace at 350 ° C. The gold film after the annealing treatment was naturally cooled to obtain gold particles with a particle size of 20 nm deposited on the quartz glass substrate.

[0078] A graphene film is prepared at 1000° C. by chemical vapor deposition, and the graphene film is grown on a 25-micron copper foil.

[0079] Coating polymethyl methacrylate on the prepared graphene film, drying in a vacuum drying oven at 170° C. for 30 minutes to obtain the first intermediate layer; The ammonium persulfate solution of / mL removes the copper foil in the first intermediate layer to obtain the second intermediate layer, and rinses the first intermediate layer with deionized water in the process of removin...

Embodiment 2

[0086] Measure 0.25mL, 0.1mol / L gold chloride aqueous solution and 100mL ultrapure water, mix, stir and heat to boiling, add 1.5mL, mass concentration of 1% trisodium citrate aqueous solution to the obtained solution for 30 minutes reaction to obtain gold sol.

[0087] Under ultrasonic conditions, the quartz glass substrate is cleaned with acetone, ethanol, and ultrapure water in sequence, and the cleaned quartz glass substrate is heat-treated at 80°C for 30 minutes with a sulfuric acid aqueous solution with a volume concentration of 75%; The heat-treated quartz glass substrate was cleaned with ultrapure water, dried in air, and set aside.

[0088] The above-mentioned heat-treated quartz glass substrate was soaked in an ethanol solution with a volume concentration of 1% of 3-aminopropyltriethoxysilane at 25°C for 2h, and the obtained 3-aminopropyltriethoxysilane The substrates were washed with ethanol and ultrapure water, dried in air, and used for later use.

[0089] Soak t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com