Non-woven cloth production device for curtain solid pin electrode nano fiber

A technology for electrospinning nanofibers and production devices, applied in non-woven fabrics, textiles and papermaking, fiber processing, etc., can solve the problems of drop spinning voltage, thick fiber diameter, clogging, etc. to the effect of the spinning voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

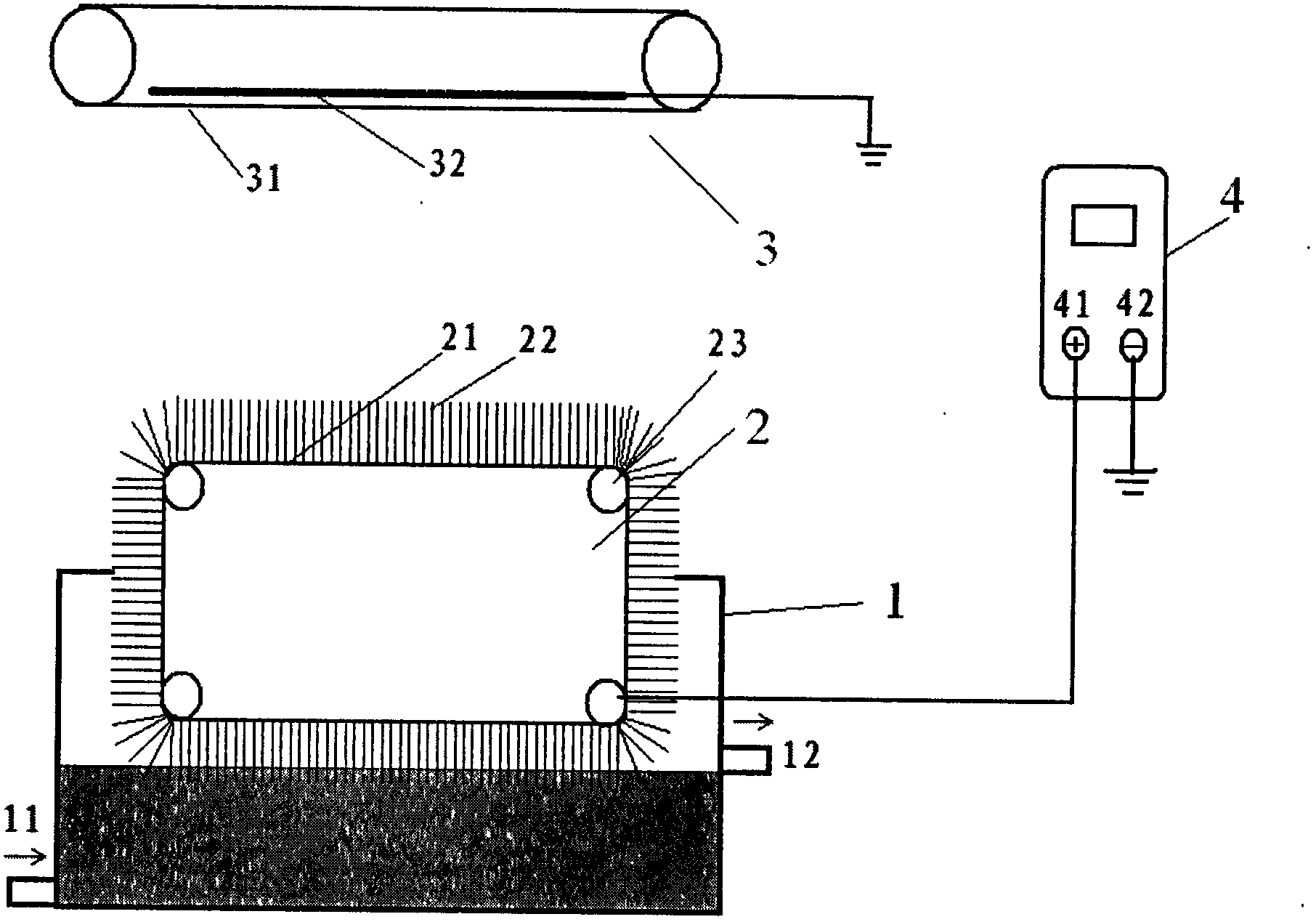

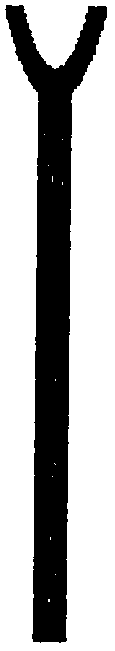

[0030] like figure 1 A curtain-type solid-needle electrospun nanofiber nonwoven fabric production device shown includes a liquid storage tank 1, a curtain-type solid-needle electrode spinneret 2, a receiving device 3, and a high-voltage electrostatic generator 4. The width of the curtain type solid needle electrode spinneret is 20cm, select as image 3 For the fork-shaped solid needle electrode shown, the length of 22 solid needle electrodes is 1cm, the width of the fork is 1mm, the depth of needle tip immersion is 0.2mm, and the needle density is 1 needle / cm 2 . During work, 30% polyvinyl alcohol / water spinning solution is injected into the liquid storage tank 1 through the liquid inlet 11, and the excess spinning solution flows out through the outlet 12, and the solid needle electrode spinneret 2 is under the action of an external force at a speed of 1m / Rotate at a rotation speed of min, turn on the high-voltage electrostatic generator 4 after the spinneret 2 rotates stab...

Embodiment 2

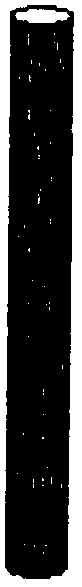

[0032] like figure 1 A curtain-type solid-needle electrospun nanofiber nonwoven fabric production device shown includes a liquid storage tank 1, a curtain-type solid-needle electrode spinneret 2, a receiving device 3, and a high-voltage electrostatic generator 4. The width of the curtain type solid needle electrode spinneret is 80cm, select as Figure 4 For the cylindrical solid needle electrode shown, the solid needle electrode has 22 needles with a length of 5cm, a needle tip immersion depth of 0.4mm, and a needle density of 16 needles / cm 2 . During work, 35% polyvinylpyrrolidone / ethanol spinning solution is injected into the liquid storage tank 1 through the liquid inlet 11, and the excess spinning solution flows out through the outlet 12, and the solid needle electrode spinneret 2 is under the action of an external force at a speed of 3m / Rotate at a rotation speed of min, and turn on the high-voltage electrostatic generator 4 after the spinneret 2 rotates stably. The po...

Embodiment 3

[0034] like figure 1 A curtain-type solid-needle electrospun nanofiber nonwoven fabric production device shown includes a liquid storage tank 1, a curtain-type solid-needle electrode spinneret 2, a receiving device 3, and a high-voltage electrostatic generator 4. The width of the curtain type solid needle electrode spinneret is 100cm, select as Figure 5 For the conical solid needle electrode shown, the length of 22 solid needle electrodes is 2cm, the depth of needle tip immersion is 0.8mm, and the density of implanted needles is 5 needles / cm 2 . During work, 25% polyurethane / N,N-dimethylformamide spinning solution is injected into the liquid storage tank 1 through the liquid inlet 11, and the excess spinning solution flows out through the outlet 12, and the solid needle electrode spinneret 2 is in the Under the action of external force, rotate at a rotation speed of 2m / min. After the spinneret 2 rotates stably, turn on the high-voltage electrostatic generator 4. The positiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com