Needleless electrostatic spinning device with porous flexible pipe

An electrospinning, flexible tube technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of low output and easy blockage of needles, achieve high electric field strength, easy expansion, and meet the needs of sufficient conduction. pass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

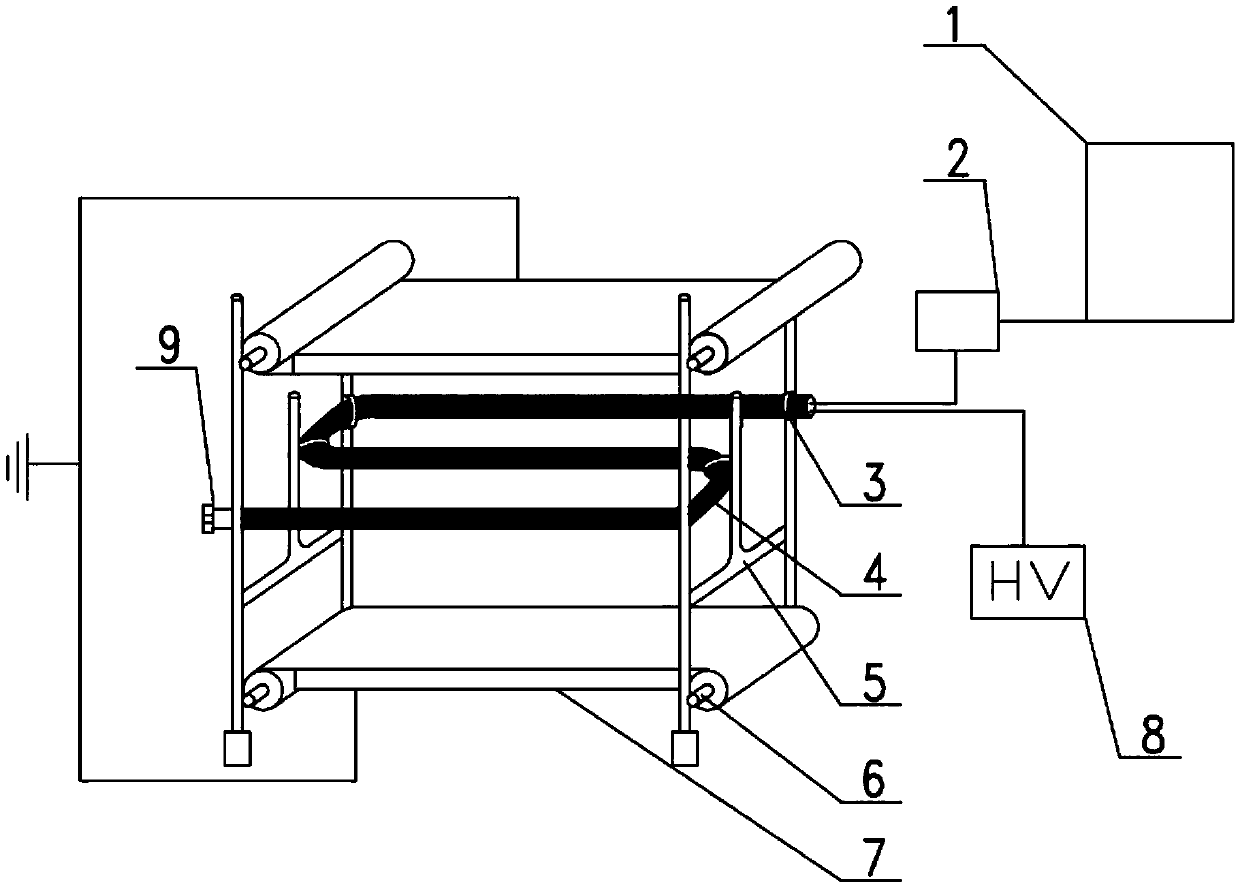

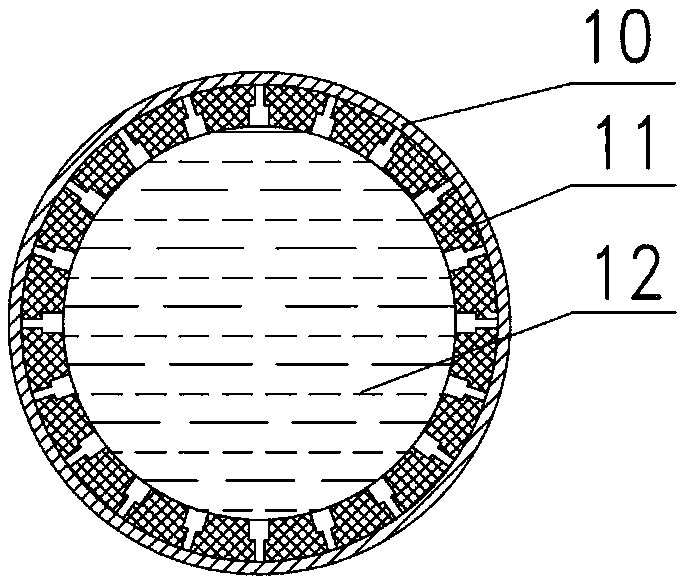

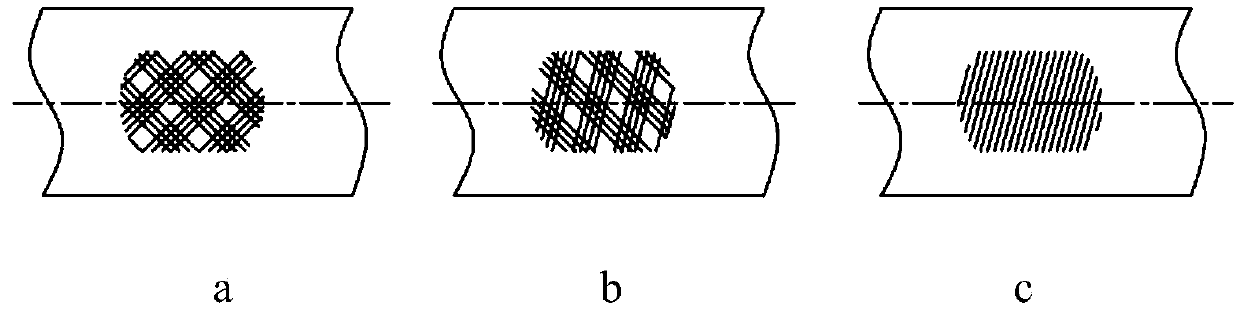

[0018] A needle-free electrospinning device for a porous flexible tube of the present invention, such as figure 1 It is a schematic diagram of the overall structure of the device, mainly including spinning solution storage chamber 1, hydraulic pump 2, porous flexible pipe 4, support frame 5, clamp 3, pipe joint 9, high-voltage electrostatic generator 8, receiving mesh curtain 7 and guide roller 6 . The hydraulic pump 2 is connected with the spinning liquid storage chamber 1, and the feeding port is located at one end of the porous flexible pipe 4, and the porous flexible pipe 4 is fixed on the support frame 5 through the clamp 3, and the clamp 3 and the support frame 5 are threaded, and the porous flexible The other end of the pipe 4 is sealed with a pipe joint 9. The metal snakeskin hose 10 on the outer layer of the porous flexible pipe 4 is used as an electrode and connected to the high-voltage electrostatic generator 8. The receiving d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com