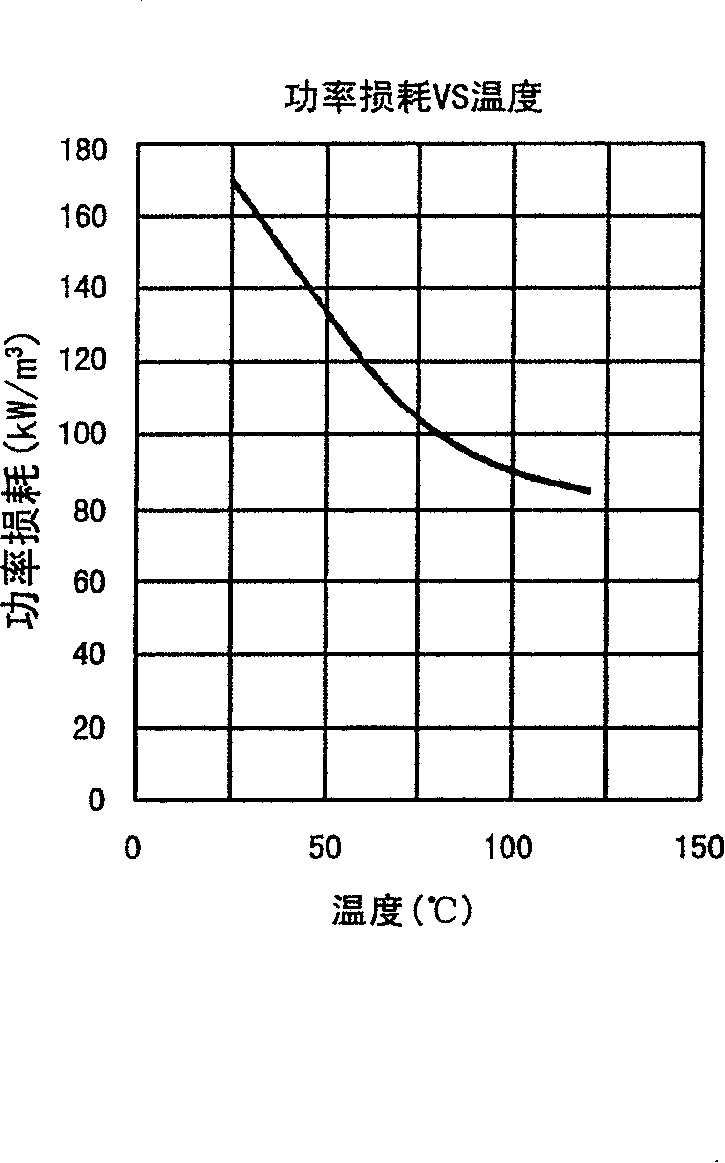

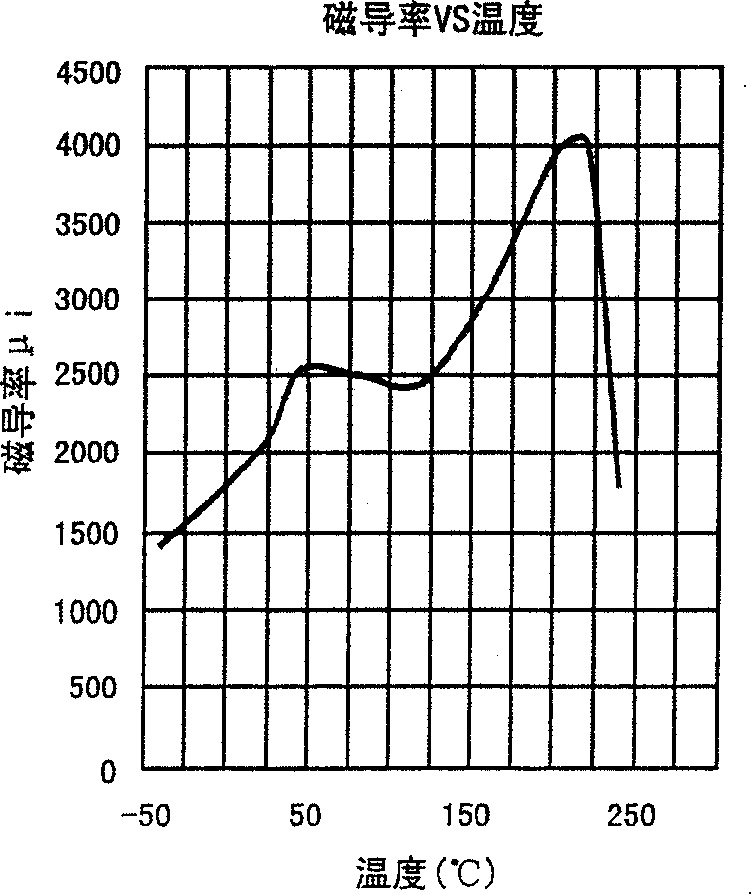

MnZn ferrite material and magnetic core for energy-saving lamp and electronic ballast

An electronic ballast, soft ferrite technology, applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, circuit, etc., can solve the problems of high saturation magnetic flux density, increased material cost, and copper consumption. Achieve the effect of low magnetic flux density, low production cost, and favorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

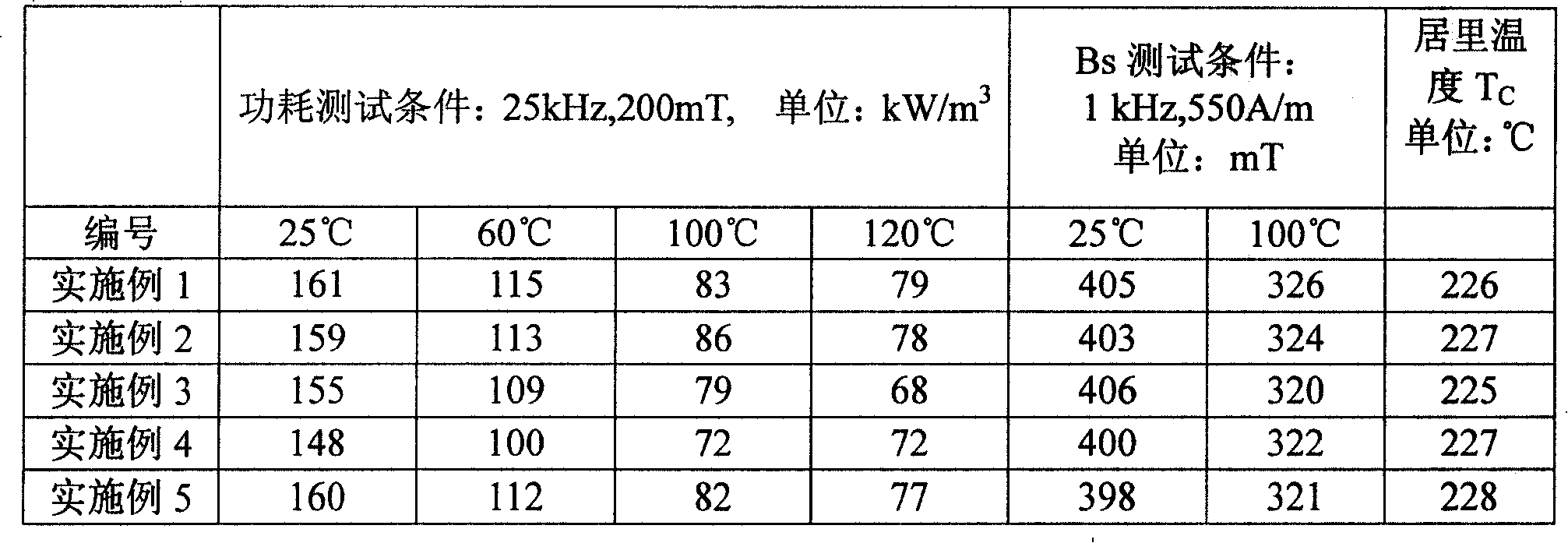

Embodiment 1

[0041] According to the formula Fe 2 o 3 : MnO: ZnO=51.2: 39.5: 9.3mol%, weigh three kinds of raw materials and put them into the stirring tank, and add 10wt% dispersant and 45wt% deionized water, stir and mix for 30 minutes, pump into the ball mill, add 10 wt% of the PVA solution with a concentration of 9% by weight of the ingredients was ground for 3 hours and then spray-dried. The dried red powder is pre-fired at a temperature of 700-1000° C. for 1 hour to obtain a pre-fired material. Weigh the calcined material and put it into the ball mill, add 100ppm, 500ppm, 600ppm, 2000ppm of SiO 2 , CaCO 3 , V 2 o 5 、TiO 2 Auxiliary small materials were added, and 10 wt% of a PVA solution with a concentration of 9% by weight of ingredients was added, ball milled for 5 hours, and spray granulated to obtain granules. Use a press to press the granular material into an annular green body with an outer diameter of 29.6 mm, an inner diameter of 17.8 mm, and a thickness of 8.9 mm. Th...

Embodiment 2

[0045] According to the formula Fe 2 o 3 : MnO: ZnO=51.0: 39.6: 9.4mol%, weigh three kinds of raw materials and put them into the stirring tank, and add 10wt% dispersant and 45wt% deionized water, stir and mix for 30 minutes, pump into the ball mill, add The concentration of 10wt% batching weight is 9% PVA solution, after grinding for 3 hours, it is spray-dried. The dried red powder is pre-fired at a temperature of 700-1000° C. for 1.5 hours to obtain a pre-fired material. Weigh the calcined material and put it into the ball mill, add 100ppm, 600ppm, 3000ppm, 800ppm of SiO 2 , CaCO 3 , SnO 2 , Nb 2 o 5 Auxiliary small materials were added, and 10 wt% of a PVA solution with a concentration of 9% by weight of ingredients was added, ball milled for 5 hours, and spray granulated to obtain granules. The pellets were pressed into a circular green body with an outer diameter of 29.6 mm, an inner diameter of 17.8 mm and a thickness of 8.9 mm with a press. The ring-shaped green...

Embodiment 3

[0048] According to the formula Fe 2 o 3 : MnO: ZnO=52.5: 38.6: 8.9mol%, weigh three kinds of raw materials and put them into the stirring tank, add 10wt% dispersant and 45wt% deionized water, stir and mix for 30 minutes, pump them into the ball mill, add The concentration of 10wt% batching weight is 9% PVA solution, after grinding for 3 hours, it is spray-dried. The dried red powder is pre-fired at a temperature of 700-1000° C. for 1.5 hours to obtain a pre-fired material. Weigh the calcined material and put it into the ball mill, add 80ppm, 600ppm, 3000ppm of SiO respectively according to the weight ratio 2 , CaCO 3 , CoO auxiliary small material, and add 10wt% batching weight concentration of 9% PVA solution, ball mill for 5 hours, spray granulation to obtain granular material. The pellets were pressed into a circular green body with an outer diameter of 29.6 mm, an inner diameter of 17.8 mm and a thickness of 8.9 mm with a press. The ring-shaped green body was kept an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com