Baking-free brick and production method thereof

A production method and the technology of burn-free bricks, which are applied in the field of building materials, can solve problems such as being only used for low-rise buildings, affecting the quality of bricks, and not finding burn-free bricks, etc., achieving high comprehensive resource utilization benefits, environmentally friendly manufacturing processes, Good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

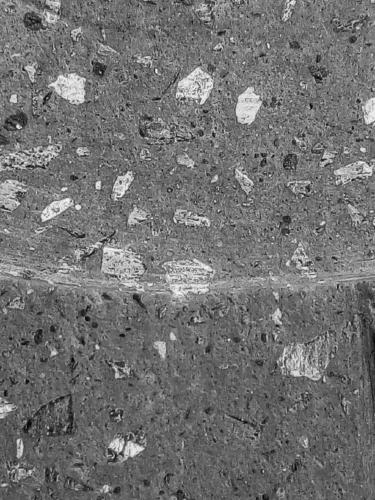

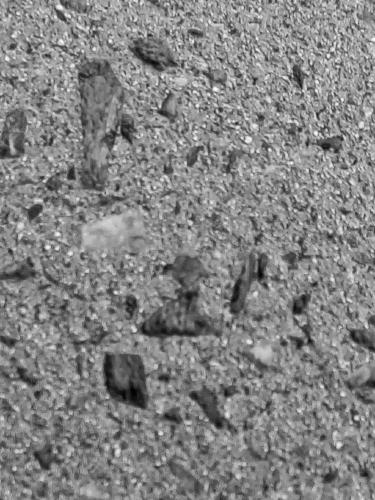

Image

Examples

Embodiment 1

[0043] A kind of unfired brick, its production method comprises the following steps:

[0044]A. The parts by weight of each component of the brick embryo raw material include: 40 parts of soil, 10 parts of recycled aggregate, 8 parts of cement, 5 parts of admixture; 1 part of fusion agent;

[0045] B. Put the soil raw material into the pulverizer, crush and roll the soil raw material and pass through a 20-mesh sieve, dry it until the water content is 12%, and transfer it to the soil silo for storage through the conveyor belt;

[0046] C. Put the recycled aggregate into the pulverizer, crush and roll the recycled aggregate until the particle size is 0.5cm, and transfer it to the recycled aggregate bin for storage through the conveyor belt;

[0047] D. Pour the soil, recycled aggregate and cement into the mixer and mix thoroughly, and add admixture, fusion agent and appropriate amount of water while stirring;

[0048] E, smear curing agent coating around the inner wall of the a...

Embodiment 2

[0061] A kind of unfired brick, its production method comprises the following steps:

[0062] A. The parts by weight of each component of the brick embryo raw material include: 20 parts of soil, 20 parts of recycled aggregate, 5 parts of cement, 1 part of admixture; 3 parts of fusion agent;

[0063] B. Put the soil raw material into the pulverizer, crush and roll the soil raw material and pass through a 20-mesh sieve, dry it until the water content is 18%, and transfer it to the soil silo for storage through the conveyor belt;

[0064] C. Put the recycled aggregate into the pulverizer, crush and roll the recycled aggregate to a particle size of 0.8cm, and transfer it to the recycled aggregate bin for storage through the conveyor belt;

[0065] D. Pour the soil, recycled aggregate and cement into the mixer and mix thoroughly, and add admixture, fusion agent and appropriate amount of water while stirring;

[0066] E, smear curing agent coating around the inner wall of the adobe...

Embodiment 3

[0076] A kind of unfired brick, its production method comprises the following steps:

[0077] A. The parts by weight of each component of the brick embryo raw material include: 30 parts of soil, 15 parts of recycled aggregate, 7 parts of cement, 3 parts of admixture; 2 parts of fusion agent;

[0078] B. Put the soil raw material into the pulverizer, crush and roll the soil raw material and pass through a 20-mesh sieve, dry it until the water content is 15%, and transfer it to the soil silo for storage through the conveyor belt;

[0079] C. Put the recycled aggregate into the pulverizer, crush and roll the recycled aggregate to a particle size of 0.6cm, and transfer it to the recycled aggregate bin for storage through the conveyor belt;

[0080] D. Pour the soil, recycled aggregate and cement into the mixer and mix thoroughly, and add admixture, fusion agent and appropriate amount of water while stirring;

[0081] E, smear curing agent coating around the inner wall of the adob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com