Preparation method of lamellar gamma-phase nano aluminum oxide

A nano-alumina and flake technology is applied in the field of preparation of flake γ-phase nano-alumina, which can solve the problems of complex process, high reaction temperature and high energy consumption, and achieves simple preparation process, increased specific surface area and high energy consumption. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

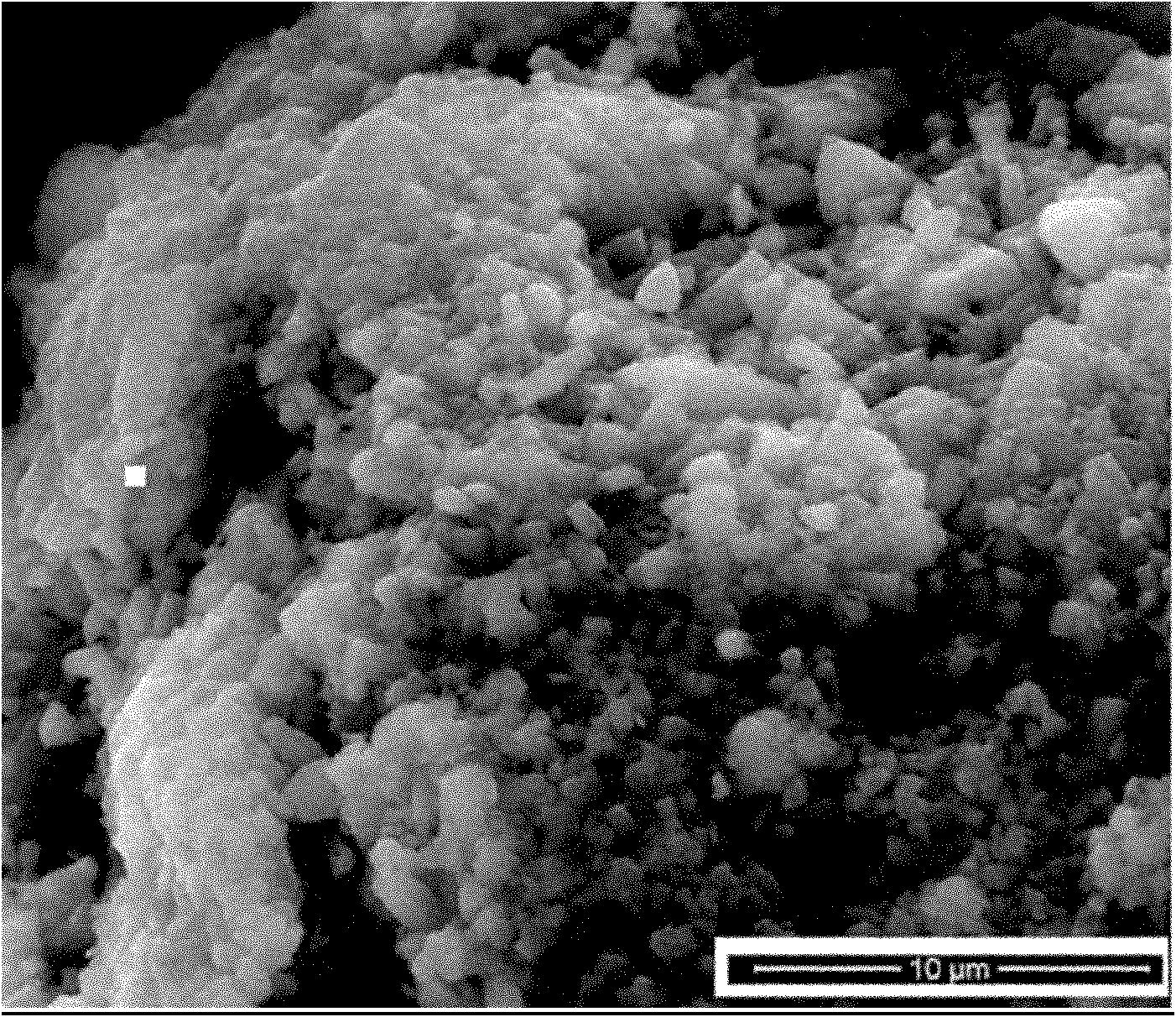

[0025] A. Put 100g of aluminum powder material with a purity greater than 99.5% and a particle size of 95-100um into a rolling vibration mill with a volume of 2.5 liters and a power of 0.12kw for grinding for 2 hours, so that the aluminum powder can be finely processed at the same time form high-energy metastable states, such as figure 1 shown;

[0026] B. Mix the prepared high-energy metastable aluminum powder with tap water in a weight ratio of 1:10, and ultrasonically vibrate for 2 hours in an ultrasonic oscillator with a power of 99 Hz to prepare white milky Al(OH) 3 colloid;

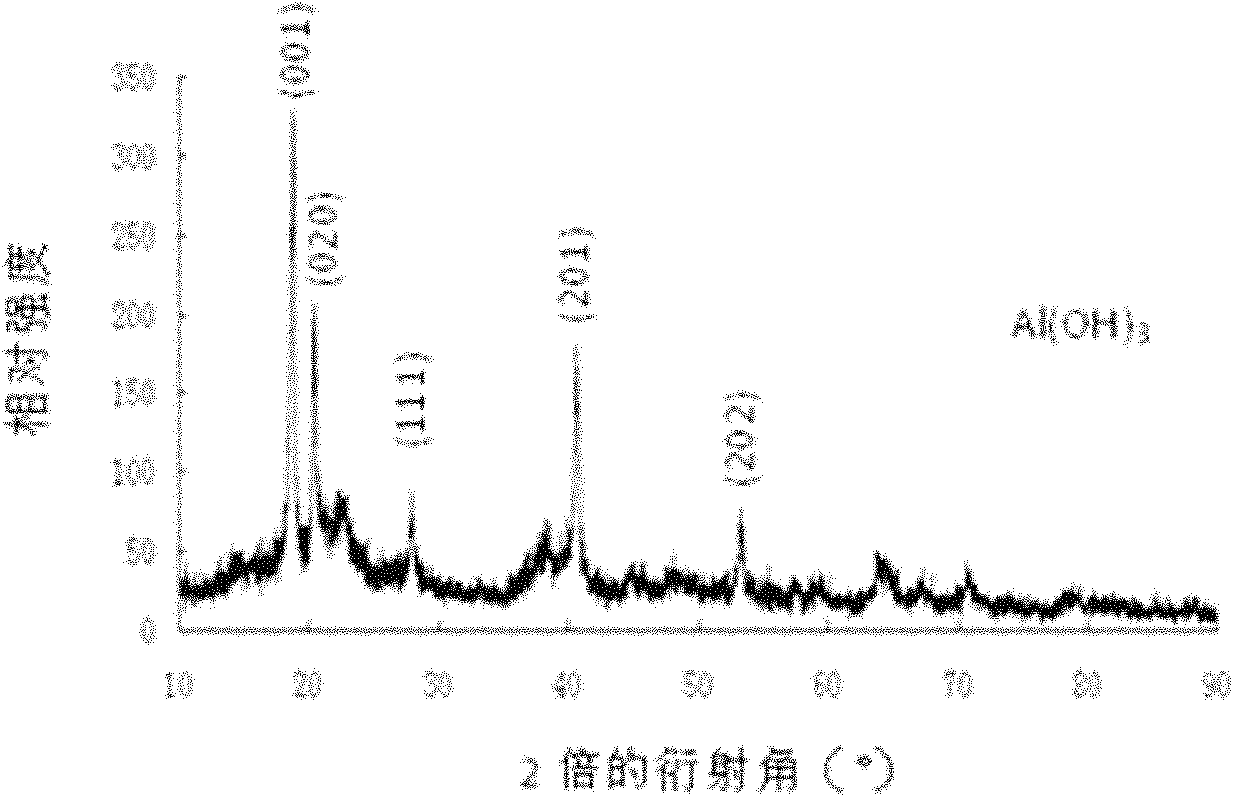

[0027] C. Put the white milky Al(OH) 3 The colloid was directly put into a constant temperature drying oven, and dried at 80°C for 6 hours to obtain Al(OH) 3 powder, whose crystal structure is diffracted as figure 2 shown;

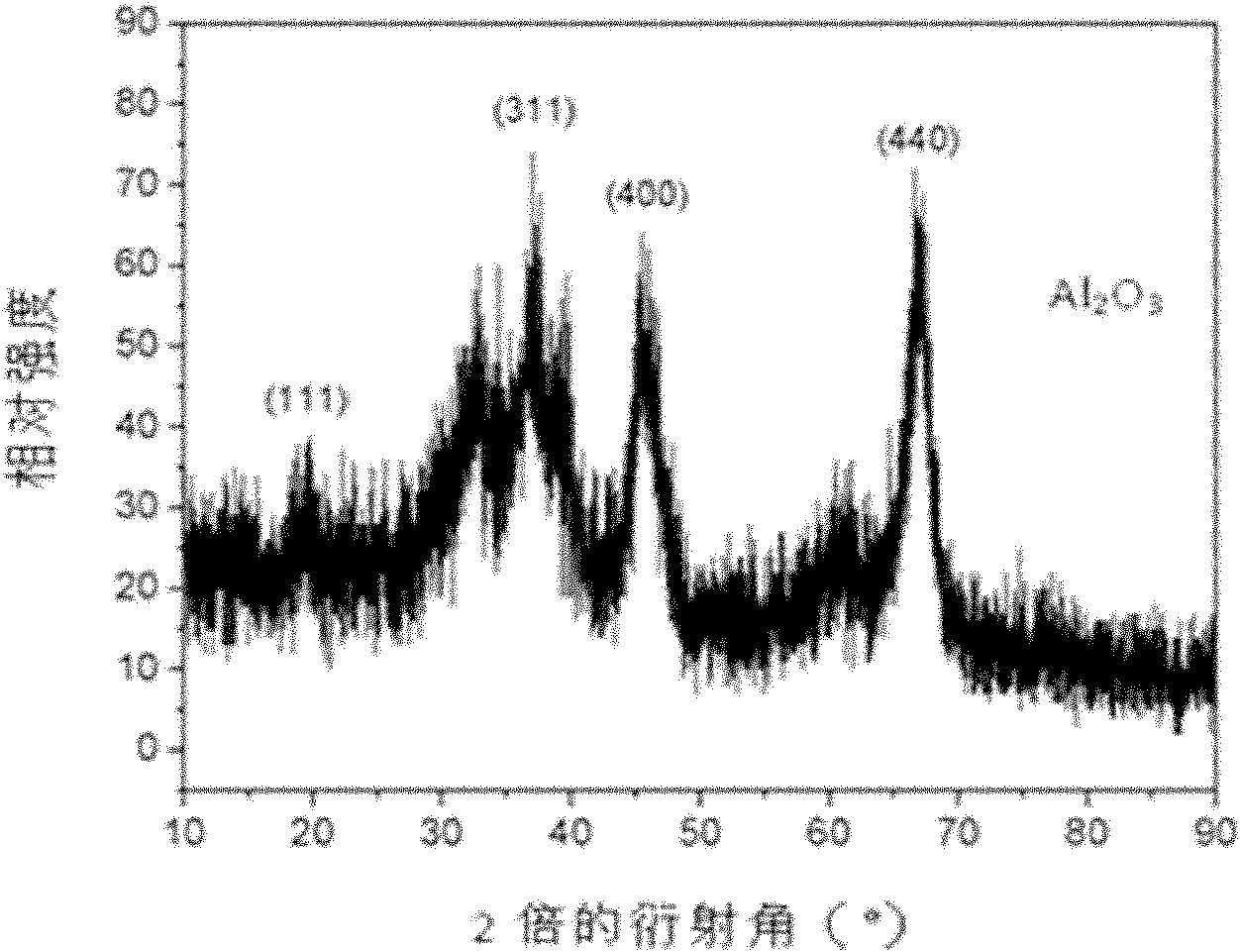

[0028] D. Put the powder into a box-type resistance furnace to dry at 160°C, and dry at a constant temperature for 4 hours to obtain γ-phase sheet-shaped nano-alumina. The...

Embodiment 2

[0030] A. Put 100g of aluminum powder material with a purity greater than 99.5% and a particle size of 95-100um into a rolling vibratory mill with a volume of 2.5 liters and a power of 0.12kw for grinding for 2 hours, so that the aluminum powder can be finely processed at the same time form high-energy metastable states, such as figure 1 shown;

[0031] B. Mix the prepared high-energy metastable aluminum powder with tap water in a weight ratio of 1:10, and ultrasonically vibrate for 2 hours in an ultrasonic oscillator with a power of 99 Hz to prepare white milky Al(OH) 3 colloid;

[0032] C. Put the white milky Al(OH) 3 The colloid was directly put into a constant temperature drying oven, and dried at 80°C for 6 hours to obtain Al(OH) 3 powder, whose crystal structure is diffracted as figure 2 shown;

[0033] D. Put the powder into a box-type resistance furnace to dry at 180°C, and dry at a constant temperature for 4 hours to obtain γ-phase sheet-shaped nano-alumina, who...

Embodiment 3

[0035] A. Put 100g of aluminum powder material with a purity greater than 99.5% and a particle size of 95-100um into the equipment with a volume of 2 figure 1 Shown; 2.5 liters, the power is 0.12kw rolling vibratory mill grinding 2h in the barrel, so that the aluminum powder forms a high-energy metastable state while finely processing,

[0036]B. Mix the prepared high-energy metastable aluminum powder with tap water at a weight ratio of 1:10, and ultrasonically vibrate for 4 hours in an ultrasonic oscillator with a power of 70 Hz to prepare white milky Al(OH) 3 colloid;

[0037] C. Add white milky Al(OH) 3 The colloid was directly put into a constant temperature drying oven, and dried at 80°C for 6 hours to obtain Al(OH) 3 powder, whose crystal structure is diffracted as figure 2 shown;

[0038] D. Put the powder into a box-type resistance furnace to dry at 210°C, and dry at a constant temperature for 4 hours to obtain γ-phase sheet-shaped nano-alumina, whose crystal stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com