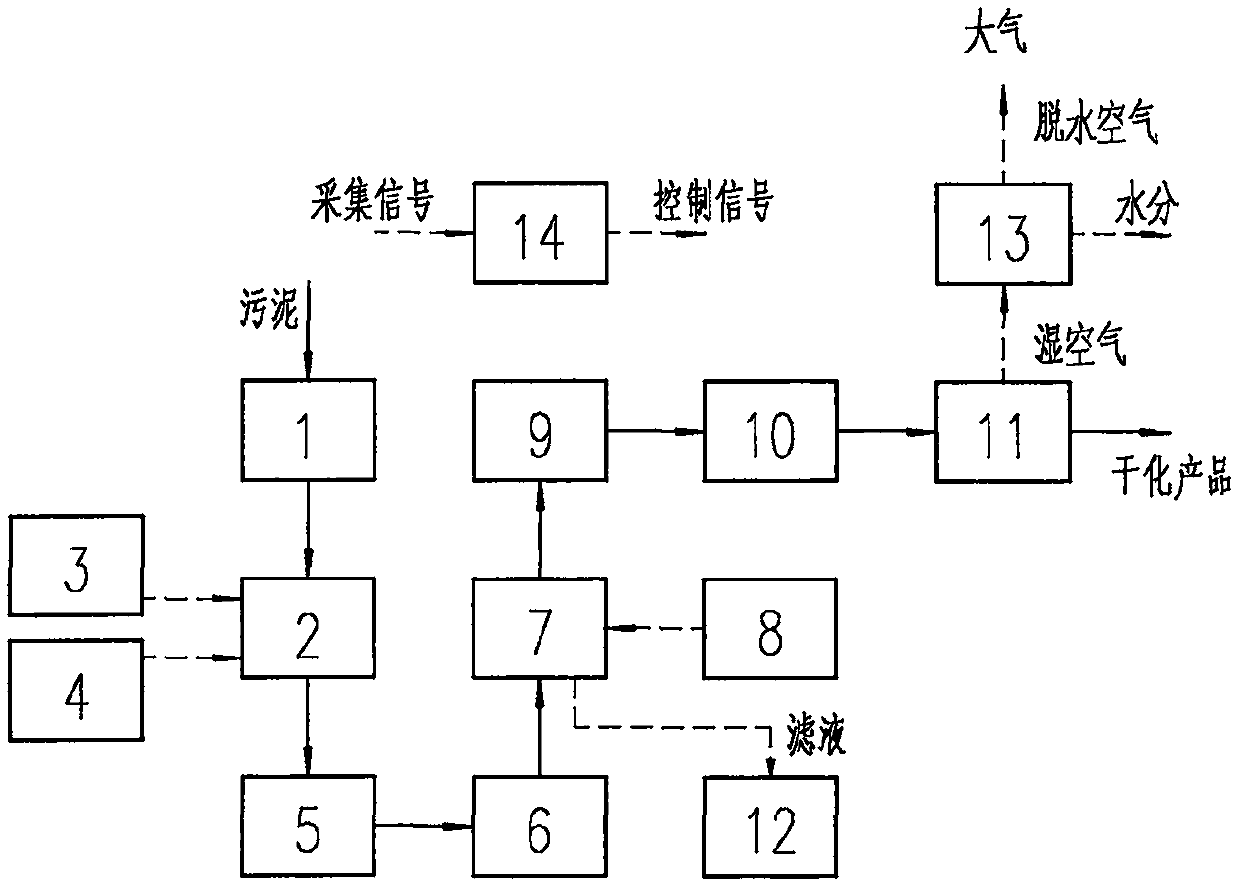

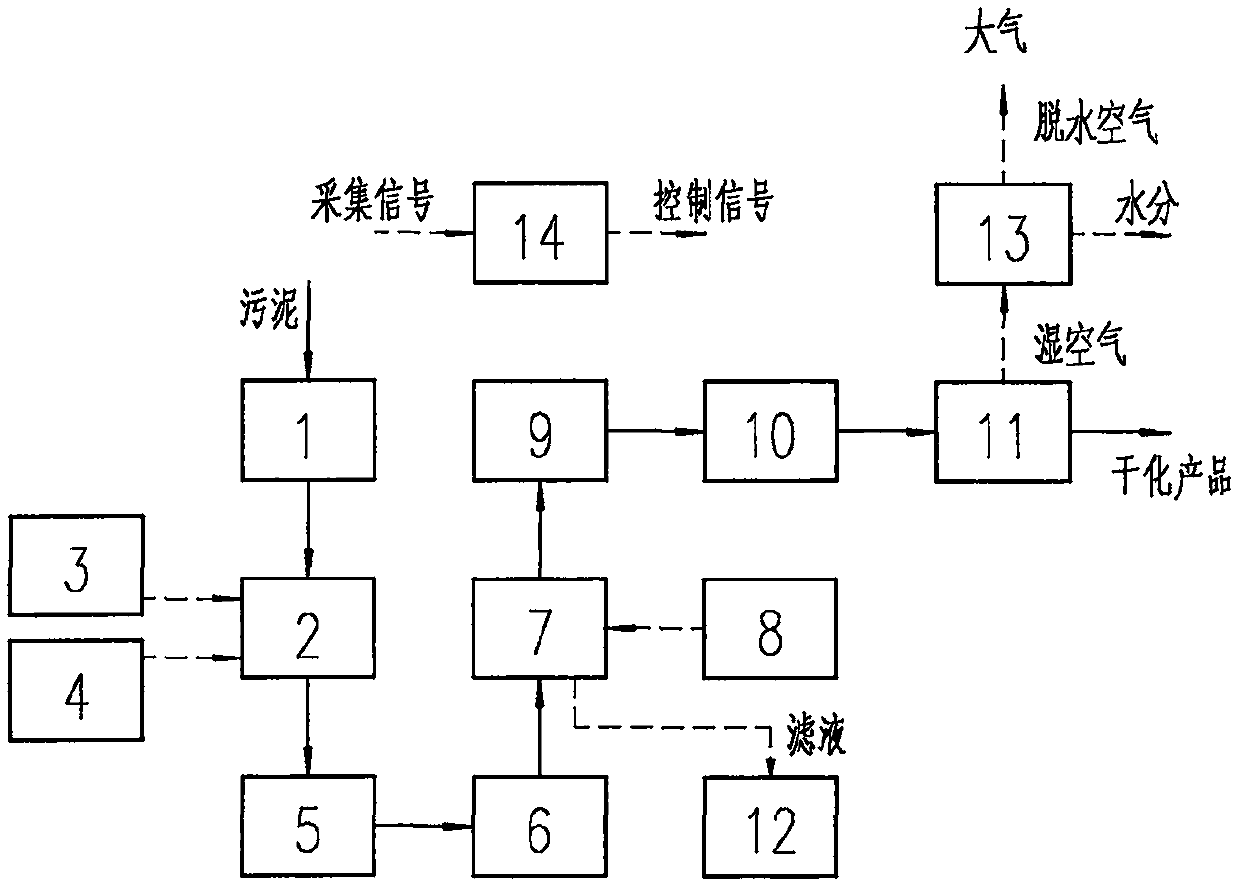

Heat-free sludge drying method and device system thereof

A sludge and drying technology, used in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as unbearable treatment costs, odor and dust generation, and limited application scope. Achieve significant energy-saving effect, reduce water viscosity, and avoid secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The excess sludge of a city sewage treatment plant has a water content of 81.2%, an organic matter content of 49.5% (dry weight), and protein content in extracellular polymers is greater than sugar content. Add 20 kg of chemical conditioner and 50 kg of physical conditioner per ton of sludge. The composition of the chemical conditioner is: cationic polyacrylamide 15%, cetyltrimethylammonium bromide 15%, polyaluminum chloride 10%, TS-01 dehydrating agent 60%; the physical conditioner is 10% water content Sawdust; Stir evenly with a mixer and send it to the reaction tank for 20 minutes; then send it to the all-round water press for 10 minutes, the moisture content of the mud cake is 56%; crush the mud cake, the particle size is not more than 30mm, and then send it to the air-dried In the warehouse, stay for 24 hours to obtain a dry product with a moisture content of 39.6%.

Embodiment 2

[0046] The sludge of an urban sludge centralized treatment plant comes from 5 domestic sewage treatment plants in the urban area. The mixed sludge has a moisture content of 83.1%, an organic matter content of 52.2% (dry weight), and a protein content of extracellular polymer greater than the sugar content. Add 19 kg of chemical conditioner and 48 kg of physical conditioner per ton of sludge. The composition of the chemical conditioner is: cationic polyacrylamide 12%, cetyltrimethylammonium bromide 13%, polyaluminum chloride 10%, TS-01 dehydrating agent 65%; the physical conditioner is 11% water content Straw crushed particles; stir evenly with a mixer and send it to the reaction tank for 20 minutes; then send it to the all-round water press for 10 minutes, the moisture content of the mud cake is 53%; crush the mud cake, the particle size is not greater than 30mm, and then send Put it into the air-drying storehouse and stay for 24 hours to obtain a dried product with a moistur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com