Method for preparing modified zinc oxide

A zinc oxide and modification technology, applied in the direction of zinc oxide/zinc hydroxide, electrical components, battery electrodes, etc., can solve the problems of unsuitability for industrial production, unenvironmental production process, unfavorable industrial production, etc., to achieve easy industrial production, Short production cycle and reduced water decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Step 1: Weigh 1000 grams of zinc oxide and 200 grams of bismuth nitrate into a ball mill jar, control the ball-to-material ratio to 25:1, ball mill the above mixture for 20 minutes, and crush the raw materials.

[0028] The second step: put 72 grams of potassium hydroxide into the ball milling jar described in the first step, and add 2 grams of deionized water, and ball mill the above mixture for 20 minutes to obtain a white powder.

[0029] The third step: put the powder obtained in the second step into a muffle furnace, heat treatment at a rate of 5°C / min, the heat treatment temperature is 450°C, and keep it warm for 1h to obtain a light yellow powder, which is the present invention. Prepared modified zinc oxide powder.

Embodiment 2

[0030] Example 2: Step 1: Weigh 500 grams of zinc oxide and 250 grams of bismuth nitrate into a ball mill jar, control the ball-to-material ratio to 30:1, ball mill the above mixture for 25 minutes, and crush the raw materials.

[0031] Step 2: Put 90 grams of potassium hydroxide into the ball mill jar described in the first step, add 5 grams of deionized water, and mill the mixture for 30 minutes to obtain a white powder.

[0032] The third step: put the powder obtained in the second step into a muffle furnace, heat treatment at a rate of 5°C / min, the heat treatment temperature is 500°C, and keep it warm for 1.5h to obtain a light yellow powder, namely The modified zinc oxide powder prepared by the invention.

Embodiment 3

[0033] Example 3: Step 1: Weigh 2000 grams of zinc oxide and 800 grams of bismuth nitrate into a ball milling tank, control the ball-to-material ratio to 20:1, ball mill the above mixture for 30 minutes, and crush the raw materials.

[0034] The second step: put 205 grams of sodium hydroxide into the ball milling jar described in the first step, and add 24 grams of deionized water, and ball mill the above mixture for 28 minutes to obtain a white powder.

[0035] The third step: put the powder obtained in the second step into a muffle furnace, heat treatment at a rate of 5°C / min, the heat treatment temperature is 400°C, and keep it warm for 2 hours to obtain a light yellow powder, namely this The modified zinc oxide powder prepared by the invention.

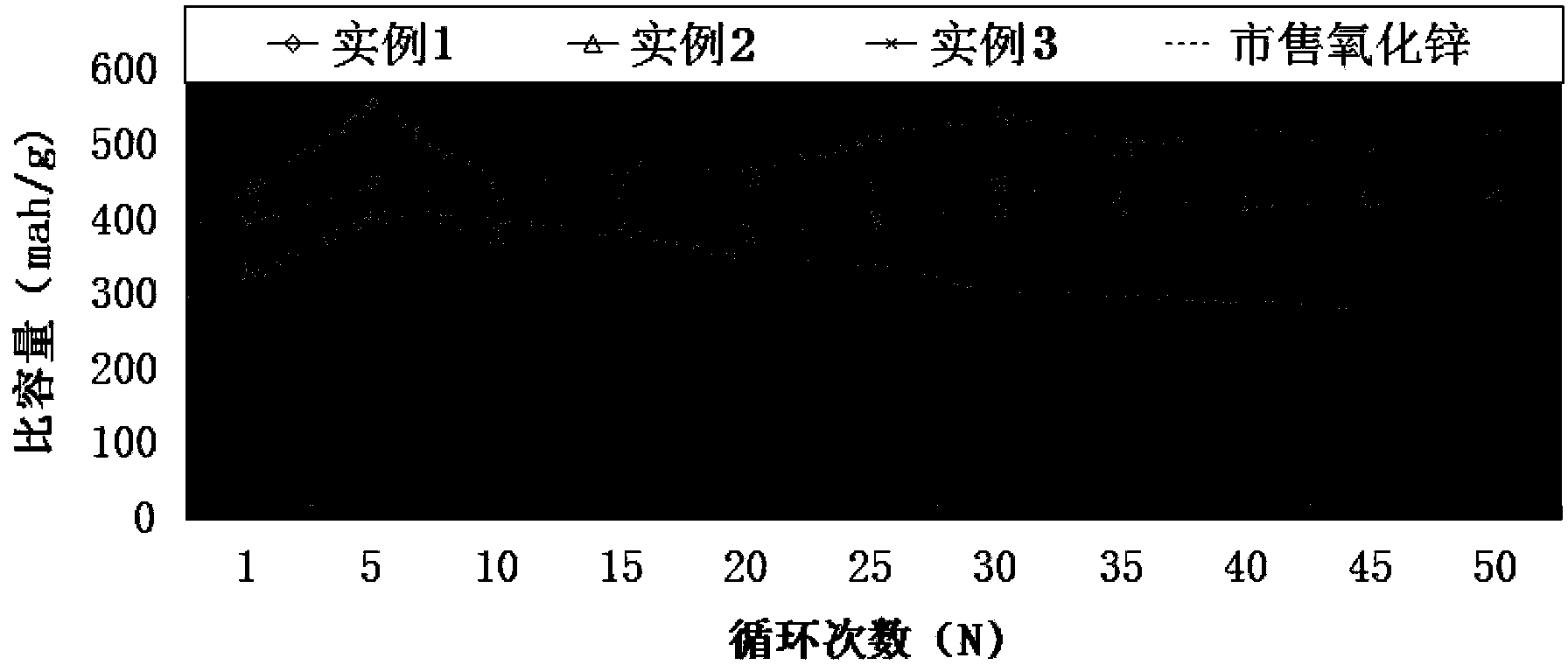

[0036] Take an appropriate amount of modified zinc oxide prepared in Examples 1-3 and commercially available zinc oxide, add an appropriate amount of PTFE emulsion and CMC as a binder, and add a small amount of deionized water at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com