Aluminum alloy anode material for batteries and preparation method of aluminum alloy anode material

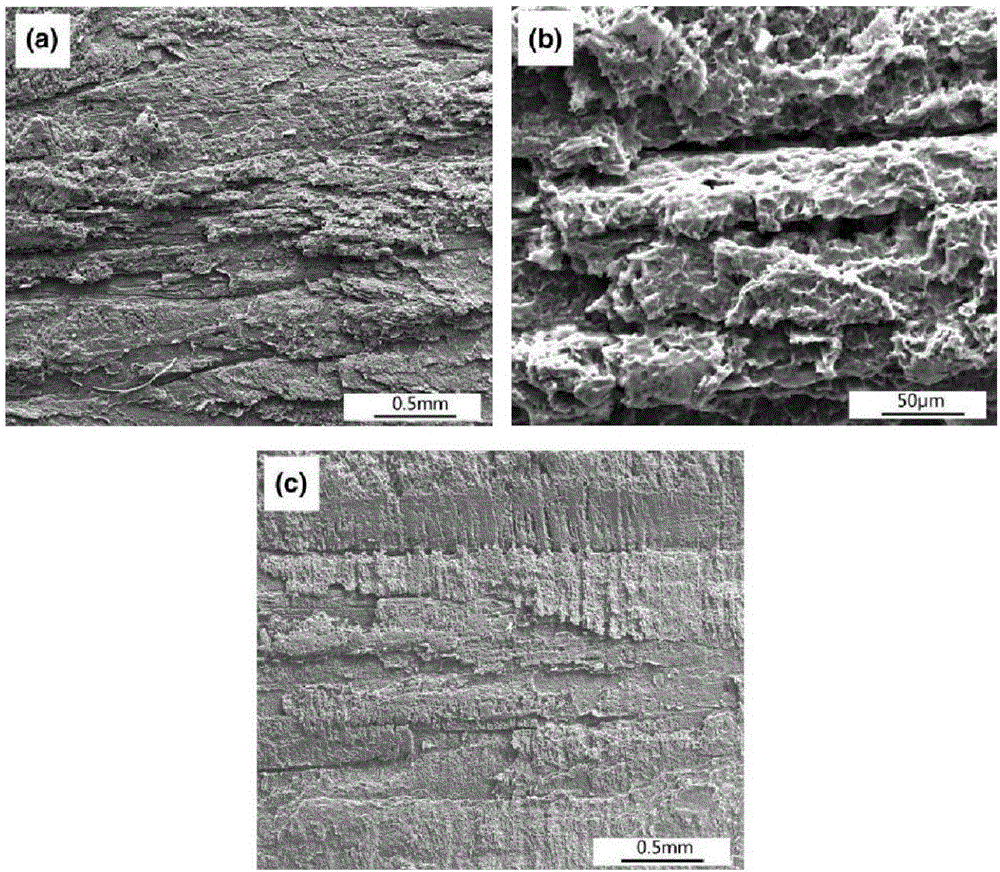

A technology of negative electrode material and aluminum alloy, which is applied in the application field of new energy materials, can solve the problems such as the drop of discharge voltage of negative electrode material and the loss of battery service function, and achieve the effects of uniform distribution, easy control of process parameters and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

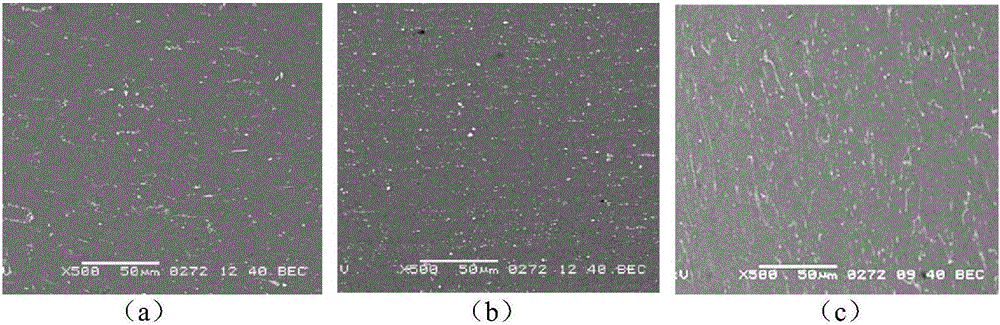

Embodiment 1

[0045] An aluminum alloy negative electrode material for batteries, which is composed of the following components in mass percentage: 0.001% lanthanum (La), 0.001% gallium (Ga), 0.001% magnesium (Mg), 0.001% indium (In), and the balance is aluminum. The purity requirement of all components is ≥99.9%.

[0046] The preparation method of the above-mentioned aluminum alloy negative electrode material for batteries comprises the following steps:

[0047] S1: According to the composition ratio of the set aluminum alloy negative electrode material, weigh the corresponding mass of aluminum and several other alloy elements (lanthanum, gallium, magnesium, indium) on the electronic balance;

[0048] S2: Heat the high-purity graphite crucible to 720°C in a resistance furnace, put metal aluminum in it, and add lanthanum to the aluminum melt after the aluminum melts, and add magnesium, indium, and gallium in order after melting; alloy elements The order of addition is from high to low acc...

Embodiment 2

[0053] An aluminum alloy negative electrode material for batteries, which is composed of the following components in mass percentage: 1% lanthanum (La), 1% gallium (Ga), 1% magnesium (Mg), 1% indium (In), and the balance is aluminum. The purity of all components is required to be ≥99.9%.

[0054] The preparation method of the above-mentioned aluminum alloy negative electrode material for batteries comprises the following steps:

[0055] S1: According to the composition ratio of the set aluminum alloy negative electrode material, weigh the corresponding mass of aluminum and alloy elements (lanthanum, gallium, magnesium, indium) on the electronic balance;

[0056] S2: Heat the high-purity graphite crucible to 750°C in a resistance furnace, put metal aluminum in it, and add lanthanum to the aluminum melt after the aluminum is melted, and add magnesium, indium, and gallium in order after melting; alloy elements The order of addition is added sequentially according to the melting...

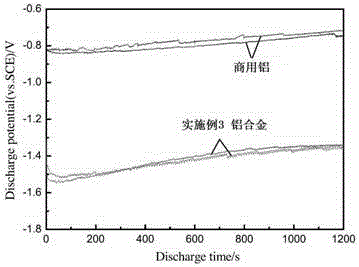

Embodiment 3

[0061] An aluminum alloy negative electrode material for batteries, consisting of the following components in mass percentage: 0.02% lanthanum (La), 0.05% gallium (Ga), 0.05% magnesium (Mg), 0.05% indium (In), and the balance is Aluminum; purity of all components ≥99.99%.

[0062] The preparation method of the above-mentioned aluminum alloy negative electrode material for batteries comprises the following steps:

[0063] S1: According to the composition ratio of the set aluminum alloy negative electrode material, weigh the corresponding mass of aluminum and alloy elements (lanthanum, gallium, magnesium, indium) on the electronic balance;

[0064] S2: Heat the high-purity graphite crucible to 730°C in a resistance furnace, put metal aluminum in it, and add lanthanum to the aluminum melt after the aluminum is melted, and add magnesium, indium, and gallium in order after melting; alloy elements The order of addition is added sequentially according to the melting point temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com