An intelligent igbt constant current driving device

A constant current drive, constant current source technology, applied in output power conversion devices, climate sustainability, high-efficiency power electronic conversion, etc., can solve the problems of small charging current, reducing switching delay and Miller plateau time, etc. Achieve the effect of reducing the area, shortening the turn-off delay, and accelerating the fall rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

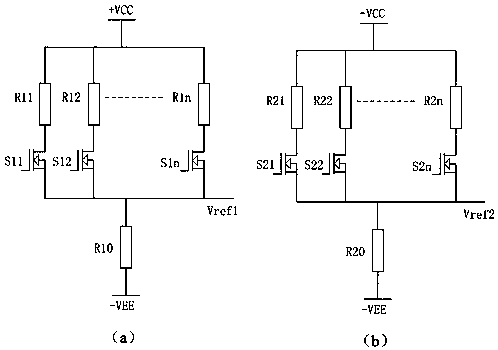

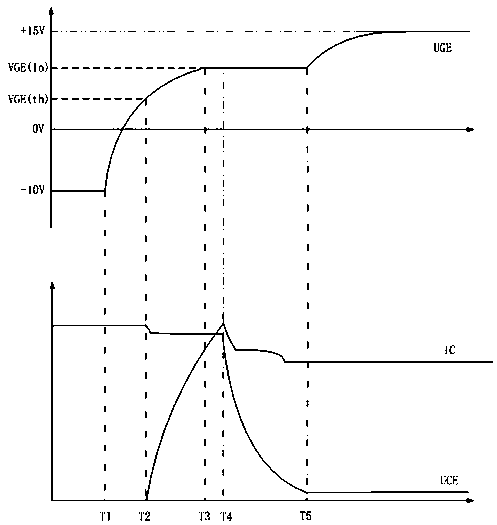

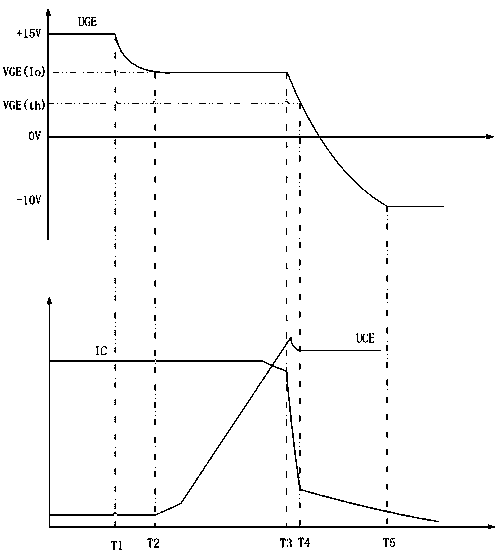

[0027] figure 1 It is a schematic diagram of an intelligent IGBT constant current drive device of the present invention, including an isolated DC-DC module, a PLD digital control module, a DAC digital-to-analog conversion module, a controlled constant current source, a voltage comparison logic circuit, a gate-level current acquisition circuit and The current comparison logic circuit is composed. The driving power and driving signal of the primary side control part are the input of the isolated DC-DC module, and the isolated driving power and driving signal are provided for the secondary side. The positive voltage of the driving power of the isolated DC-DC module is +VCC, and the negative voltage For -VEE, it provides power for the subsequent PLD digital control module, DAC digital-to-analog conversion module, controlled constant current sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com