A method for regulating the generation of oxidized cellulose in the process of oxidative degumming of ramie

A technology of oxidative cellulose and oxidative degumming, which is applied in the direction of chemical production of bast fibers, etc., to achieve the effect of optimal control, quality assurance, and improvement of degumming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

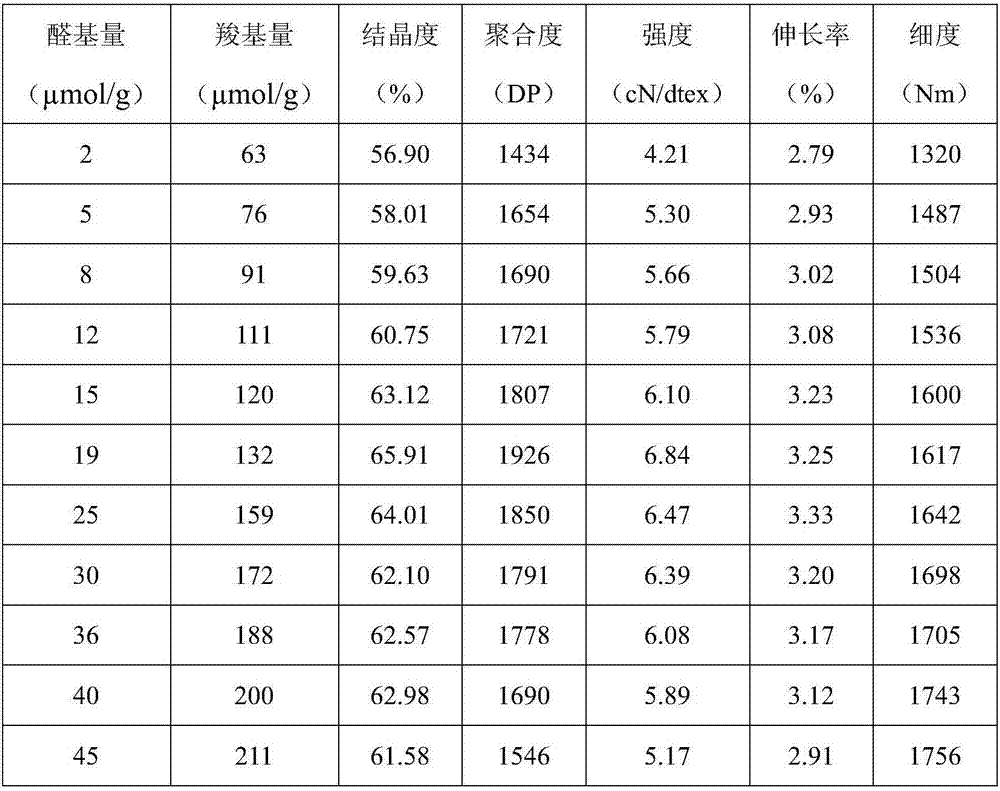

Embodiment 1

[0025] A method for regulating the generation of oxidized cellulose in the process of oxidative degumming of ramie is as follows:

[0026] With hydrogen peroxide 1.0kg, sodium benzoate 0.5kg, urea 0.4kg, sodium tripolyphosphate 0.3kg, sodium polyacrylate 0.3kg, add 97.5kg water and be made into degumming liquid (the mass ratio of ramie hemp and degumming liquid is 1: 10). Immerse 10 kg of ramie raw material in the degumming solution, adjust the pH value of the degumming solution to 10.0 with 0.1 mol / L NaOH solution, and continuously stir the mixture of ramie raw material and degumming solution at a speed of 200 rpm with a magnetic stirrer. Raise the temperature from room temperature to 85°C at a rate of 2°C / min, keep it at this temperature for 100min, and use the oxidizing properties of peroxide to fully remove the gum in the raw ramie. As the reaction progressed, the ramie fibers in the degumming process were sampled at different time points, and the functional group content...

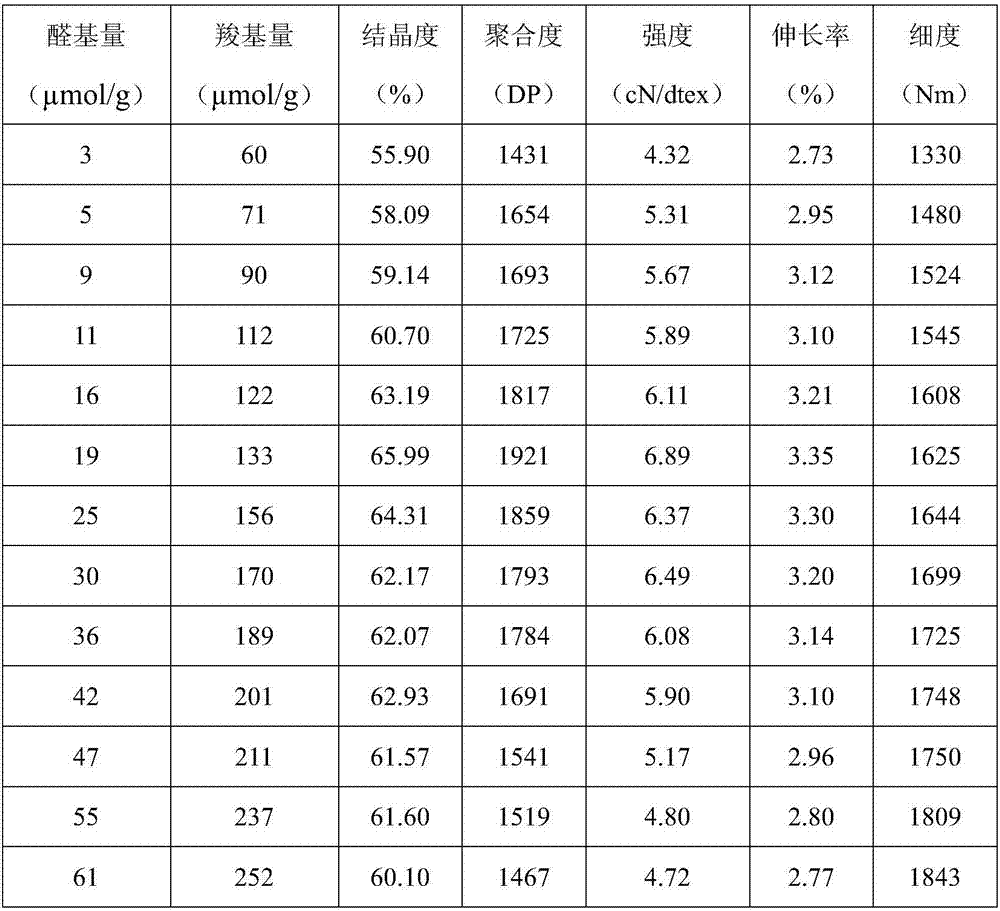

Embodiment 2

[0033] A method for regulating the generation of oxidized cellulose in the process of oxidative degumming of ramie is as follows:

[0034] With sodium percarbonate 0.2kg, acetanilide 0.05kg, urea 0.05kg, sodium dodecylbenzenesulfonate 0.05kg, sodium tartrate 0.05kg, add 99.6kg water and be made into degumming liquid (the mass ratio of ramie raw hemp and degumming liquid is 1:10). Immerse 10kg of ramie raw material in the degumming solution, adjust the pH value of the degumming solution to 14.0 with 0.1mol / L NaOH solution, and continuously stir the mixture of ramie raw material and degumming solution at a speed of 200rpm with a magnetic stirrer. Raise the temperature from room temperature to 50°C at a rate of 1°C / min, keep it at this temperature for 150min, and use the oxidizing property of peroxide to fully remove the gum in the raw ramie. As the reaction progressed, the ramie fibers in the degumming process were sampled at different time points, and the functional group cont...

Embodiment 3

[0039] A method for regulating the generation of oxidized cellulose in the process of oxidative degumming of ramie is as follows:

[0040] With urea peroxide 0.8kg, sodium citrate 0.4kg, thiourea 0.2kg, sodium metaphosphate 0.2kg, sodium polyacrylate 0.1kg, add 98.3kg water and be made into degumming liquid (the mass ratio of ramie hemp and degumming liquid is 1 :10). Immerse 10 kg of ramie raw material in the degumming solution, adjust the pH value of the degumming solution to 8.0 with 0.1 mol / L NaOH solution, and continuously stir the mixture of ramie raw material and degumming solution at a speed of 200 rpm with a magnetic stirrer. Raise the temperature from room temperature to 100°C at a rate of 5°C / min, keep it at this temperature for 40 minutes, and use the oxidizing property of peroxide to fully remove the gum in the raw ramie. As the reaction progressed, the ramie fibers in the degumming process were sampled at different time points, and the functional group content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com