Anode material for alkaline aluminum-air battery and preparation method of anode material

An anode material and air battery technology, applied in the direction of primary battery electrodes, battery electrodes, fuel cell half-cells and primary battery half-cells, etc., can solve the problem of reduced reactivity of aluminum anodes, insufficient discharge voltage, battery Potential positive shift and other issues, to achieve the effect of improving electrochemical activity, reducing hydrogen evolution behavior, and slowing hydrogen evolution corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

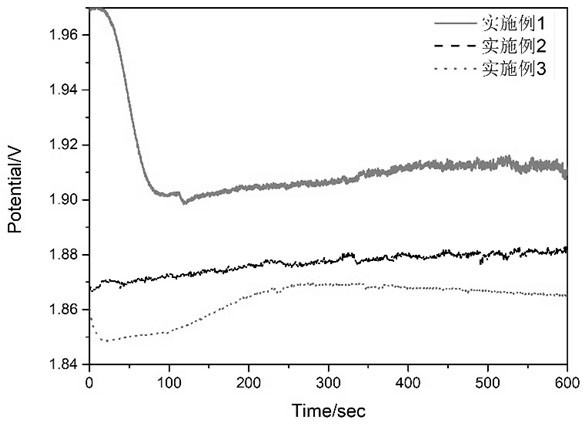

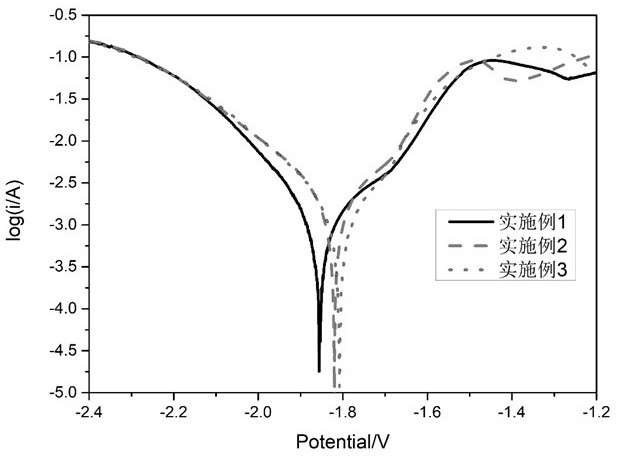

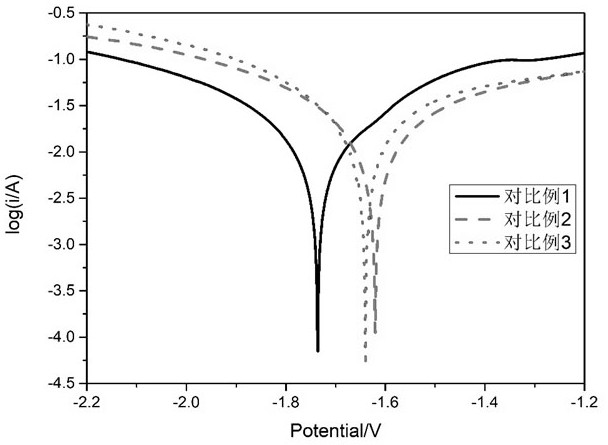

Embodiment 1

[0026] The Al-Zn-In-Sn microalloyed aluminum alloy anode material for alkaline aluminum-air batteries described in this embodiment consists of the following components by weight percentage: Zn 1wt.%, Sn 0.1wt.%, In 0.1wt. %, unavoidable impurities 0.01wt.%, and the balance is Al.

[0027] The preparation method of the Al-Zn-In-Sn microalloyed aluminum alloy anode material for the above-mentioned alkaline aluminum-air battery comprises the following steps:

[0028] Step 1: Select 4N pure aluminum ingots (purity ≥ 99.99%), high-purity metal zinc particles (purity ≥ 99.99%), high-purity metal indium powder (purity ≥ 99.99%), high-purity metal tin powder (purity ≥ 99.99%) ) as the raw material;

[0029] Step 2: Polish the surface of the 4N pure aluminum ingot with sandpaper, then clean it with absolute ethanol to remove oil and other impurities on the surface, and finally place the 4N pure aluminum ingot in an oven at 60°C for 1 hour. Weigh high-purity Zn particles, high-purity ...

Embodiment 2

[0036] The Al-Zn-In-Sn microalloyed aluminum alloy anode material for alkaline aluminum-air batteries described in this embodiment consists of the following components by weight percentage: Zn 1wt.%, Sn 0.05wt.%, In 0.1wt. %, unavoidable impurities 0.01wt.%, and the balance is Al.

[0037] The preparation method of the Al-Zn-In-Sn microalloyed aluminum alloy anode material for the above-mentioned alkaline aluminum-air battery comprises the following steps:

[0038] Step 1: Select 4N pure aluminum ingots (purity ≥ 99.99%), high-purity metal zinc particles (purity ≥ 99.99%), high-purity metal indium powder (purity ≥ 99.99%), high-purity metal tin powder (purity ≥ 99.99%) ) as the raw material;

[0039] Step 2: Polish the surface of the 4N pure aluminum ingot with sandpaper, then clean it with absolute ethanol to remove oil and other impurities on the surface, and finally place the 4N pure aluminum ingot in an oven at 60°C for 1 hour. Weigh high-purity Zn particles, high-purity...

Embodiment 3

[0046] The Al-Zn-In-Sn microalloyed aluminum alloy anode material for alkaline aluminum-air batteries in this embodiment consists of the following components by weight percentage: Zn 0.5wt.%, Sn 0.05wt.%, In 0.05wt.% , 0.01wt.% of unavoidable impurities, and the balance is Al.

[0047] Refer to Example 1 for the preparation method of the Al-Zn-In-Sn microalloyed aluminum alloy anode material for the above-mentioned alkaline aluminum-air battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com