ta‑zr‑c ternary ceramic and preparation method thereof

A ternary ceramic, ta-zr-c technology, applied in the field of inorganic materials, can solve the problems of low conversion rate, impure product, large product particle size, etc., and achieve high reactivity, good crystallinity and complete crystal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

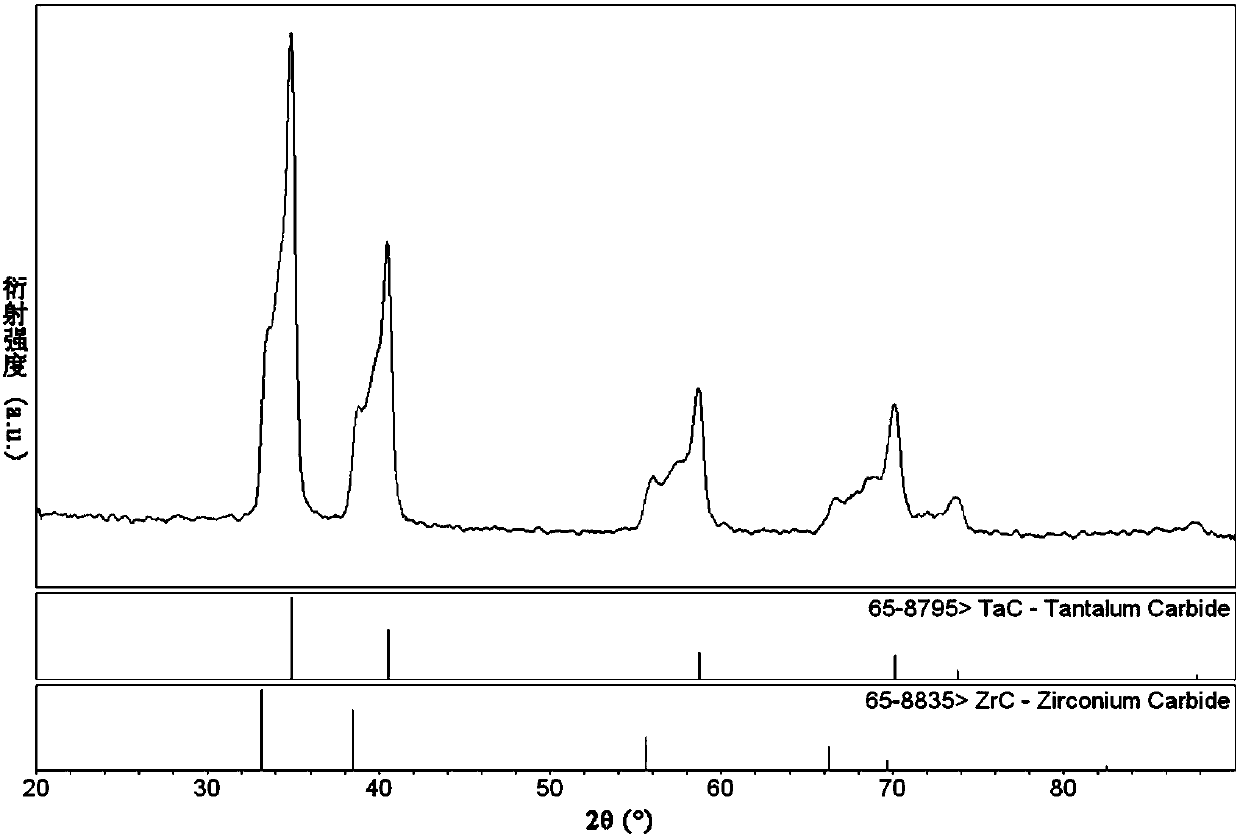

[0036] A Ta-Zr-C ternary ceramic of the present invention is a Ta-Zr-C continuous single-phase solid solution ceramic powder in which Zr atoms are dissolved in TaC, and the density is 10.44g / cm 3 , The particle size of the ceramic powder is less than 500nm, and the average particle size is 228.3nm.

[0037] A kind of preparation method of the Ta-Zr-C ternary ceramic of above-mentioned present embodiment, comprises the following steps:

[0038] (1) Preparation of precursor solution: with TaCl 5 and ZrOCl 2 ∙8H 2 O is the precursor, the mixture of acetylacetone (chelating agent) and methanol is the first solvent, and the molar ratio of TaCl 5 : ZrOCl 2 ∙8H 2O: acetylacetone: methanol = 1:1:6:72, 3.58gTaCl 5 and 3.22 g ZrOCl 2 ∙8H 2 O was slowly added to the mixed solution of 6.0g acetylacetone and 23.04g methanol, and kept stirring to obtain a precursor solution containing tantalum and zirconium; with phenolic resin as the carbon source precursor, and the mixed solution ...

Embodiment 2

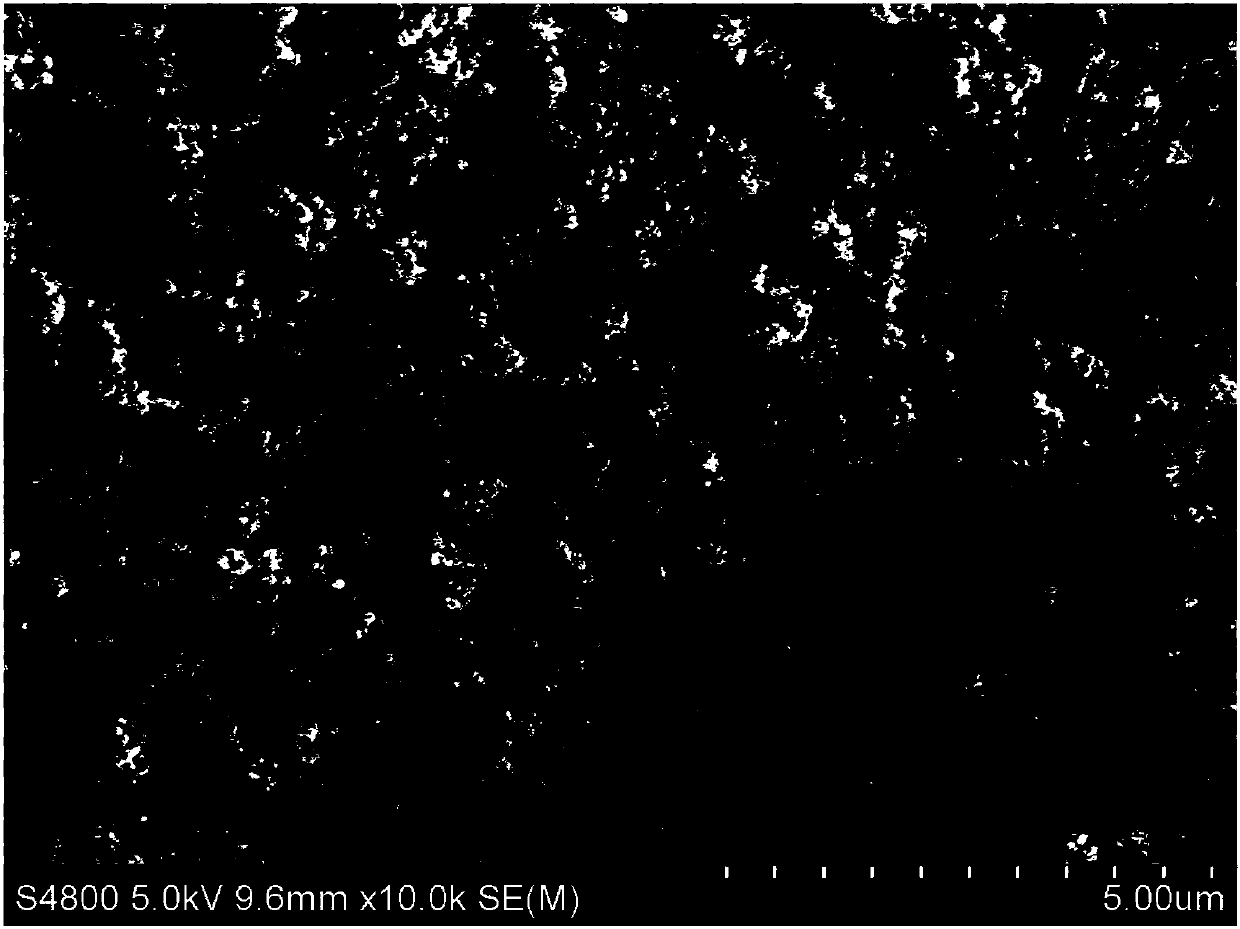

[0045] A Ta-Zr-C ternary ceramic of the present invention is a Ta-Zr-C continuous single-phase solid solution ceramic powder in which Zr atoms are solid-dissolved in TaC, and the density is 11.32g / cm 3 , The particle size of the ceramic powder is less than 500nm, and the average particle size is 216.7nm.

[0046] A kind of preparation method of the Ta-Zr-C ternary ceramic of above-mentioned present embodiment, comprises the following steps:

[0047] (1) Preparation of precursor solution: with TaCl 5 and Zr(NO 3 ) 4 ∙5H 2 O is the precursor containing tantalum and zirconium, and the mixture of ethylene glycol (chelating agent) and ethanol is used as the first solvent, and the molar ratio of TaCl 5 : Zr(NO 3 ) 4 ∙5H 2 O: ethylene glycol: ethanol = 2: 1: 7.5: 80, 3.58g TaCl 5 and 2.15g Zr(NO 3 ) 4 ∙5H 2 O is slowly added in the mixed solution of 2.325g ethylene glycol and 18.4g ethanol, constantly stirs, obtains the precursor solution containing tantalum and zirconium;...

Embodiment 3

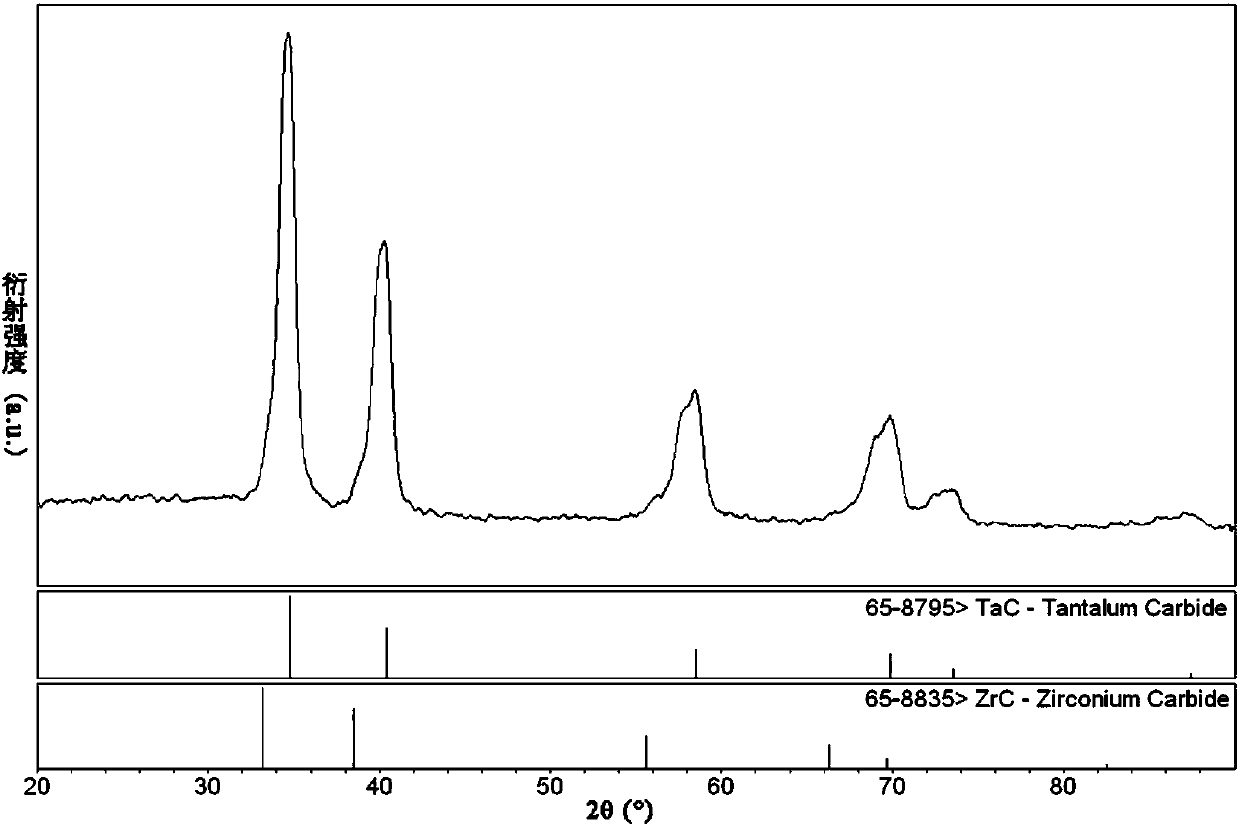

[0054] A Ta-Zr-C ternary ceramic of the present invention is a Ta-Zr-C continuous single-phase solid solution ceramic powder in which Zr atoms are dissolved in TaC, and the density is 12.47g / cm 3 , The particle size of the ceramic powder is less than 500nm, and the average particle size is 220.8nm.

[0055] A kind of preparation method of the Ta-Zr-C ternary ceramic of above-mentioned present embodiment, comprises the following steps:

[0056] (1) Preparation of precursor solution: with TaCl 5 and ZrCl 4 It is a precursor containing tantalum and zirconium, and the mixture of acetylacetone (chelating agent) and ethanol is used as the first solvent, and the molar ratio of TaCl 5 : ZrCl 4 : acetylacetone: ethanol = 4: 1: 10: 90, 3.58g TaCl 5 and 0.58gZrCl 4 Slowly add in the mixed solution of 2.50g acetylacetone and 10.35g ethanol, stir constantly, obtain the precursor solution containing tantalum and zirconium; With phenolic resin as the carbon source precursor, with the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com