Anti-self-corrosion metal-air battery as well as preparation method and application thereof

A metal-air battery and air battery technology, which is applied to fuel cells, fuel cell-type half-cells, primary cell-type half-cells, fuel cell additives, etc. Problems such as worsening properties and increasing difficulty in research on multi-component alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

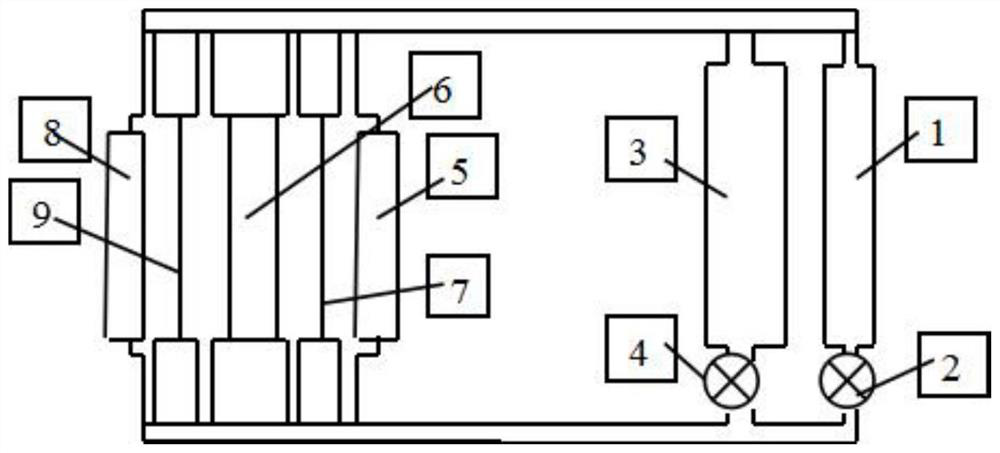

[0039] The present invention also provides a method for preparing the anti-self-corrosion metal-air battery described in the above technical solution, comprising the following steps:

[0040] Use 3D printing to print the main body model of the battery to obtain the battery frame structure;

[0041] In the battery frame structure, after connecting the non-conductive oil storage tank, oil micropump, electrolyte storage tank, electrolyte micropump, air cathode, metal anode and diaphragm, they are sealed with alkali-resistant materials to obtain the anti-self-corrosion Metal Air Batteries.

[0042] In the present invention, the Solidwords modeling tool is preferably used for modeling in the 3D printing step.

[0043] In the present invention, the model built by the Solidwords modeling tool is preferably exported to an STL format file, and the STL format file is a file recognizable by a 3D printer to print the battery frame structure.

[0044] In the present invention, the metal ...

Embodiment 1

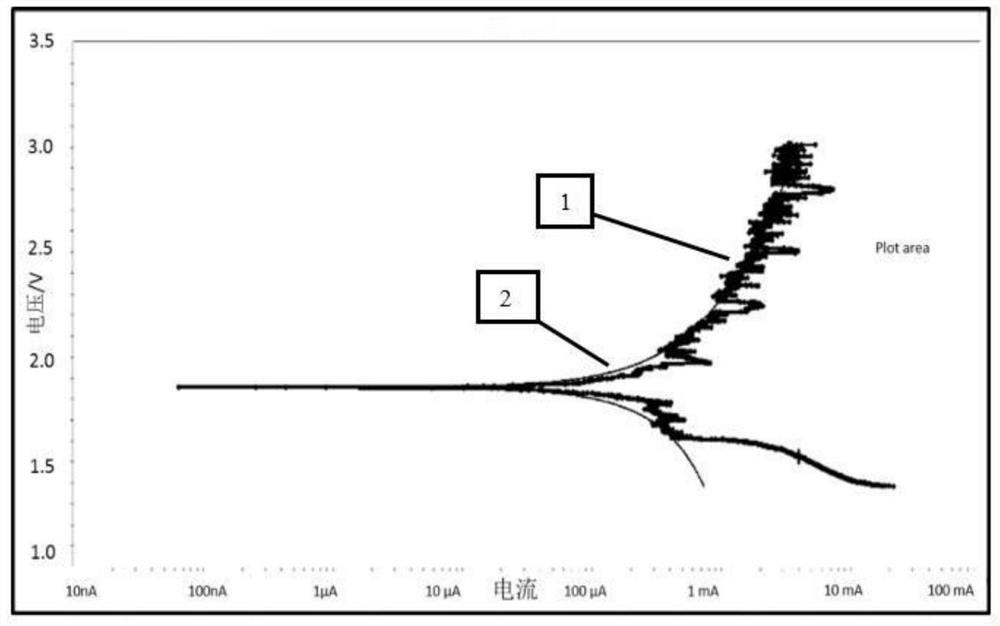

[0052] Anti-self-corrosion aluminum-air battery comprising non-conductive oil storage tank, oil micropump, electrolyte storage tank, electrolyte micropump, air cathode, aluminum anode and separator between said air cathode and metal anode, the There is an anode gap between the diaphragm and the metal anode, there is a cathode gap between the diaphragm and the air cathode, the non-conductive oil storage tank, the oil micropump and the anode gap are connected in sequence, and the electrolyte storage tank and the electrolyte micropump After connection, connect with the anode space and the cathode space respectively, the aluminum alloy anode is Al0.6Mg0.05Ga0.1In, the material of the diaphragm is polytetrafluoroethylene (PTFE), the pore size is 1 μm, and the non-conductive oil storage tank is Italian brand Solvay Fomblin produces YLVAC06 / 6 perfluoropolyether oil with the smallest viscosity and lightest weight. There is a check valve between the non-conductive oil storage tank and t...

Embodiment 2

[0071] Anti-self-corrosion magnesium-air battery, comprising a non-conductive oil storage tank, an oil micropump, an electrolyte storage tank, an electrolyte micropump, an air cathode, a magnesium anode, and a diaphragm between the air cathode and magnesium anode, the There is an anode gap between the diaphragm and the metal anode, there is a cathode gap between the diaphragm and the air cathode, the non-conductive oil storage tank, the oil micropump and the anode gap are connected in sequence, and the electrolyte storage tank and the electrolyte micropump After connecting, connect with the anode space and cathode space respectively, the metal anode is magnesium alloy anode Mg9Al1.5Sn, the material of the diaphragm is polytetrafluoroethylene (PTFE), the pore size is 1 μm, and the non-conductive oil storage tank is Italian brand Solvay Fomblin produces YLVAC06 / 6 perfluoropolyether oil with the smallest viscosity and lightest weight. There is a check valve between the non-conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com