Range hood with auxiliary air inlet channel

A technology of range hood and auxiliary air intake, applied in the field of range hood, can solve the problems of limited air intake area of grille, escape of oil fume, no air intake way, etc. The effect of fume escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

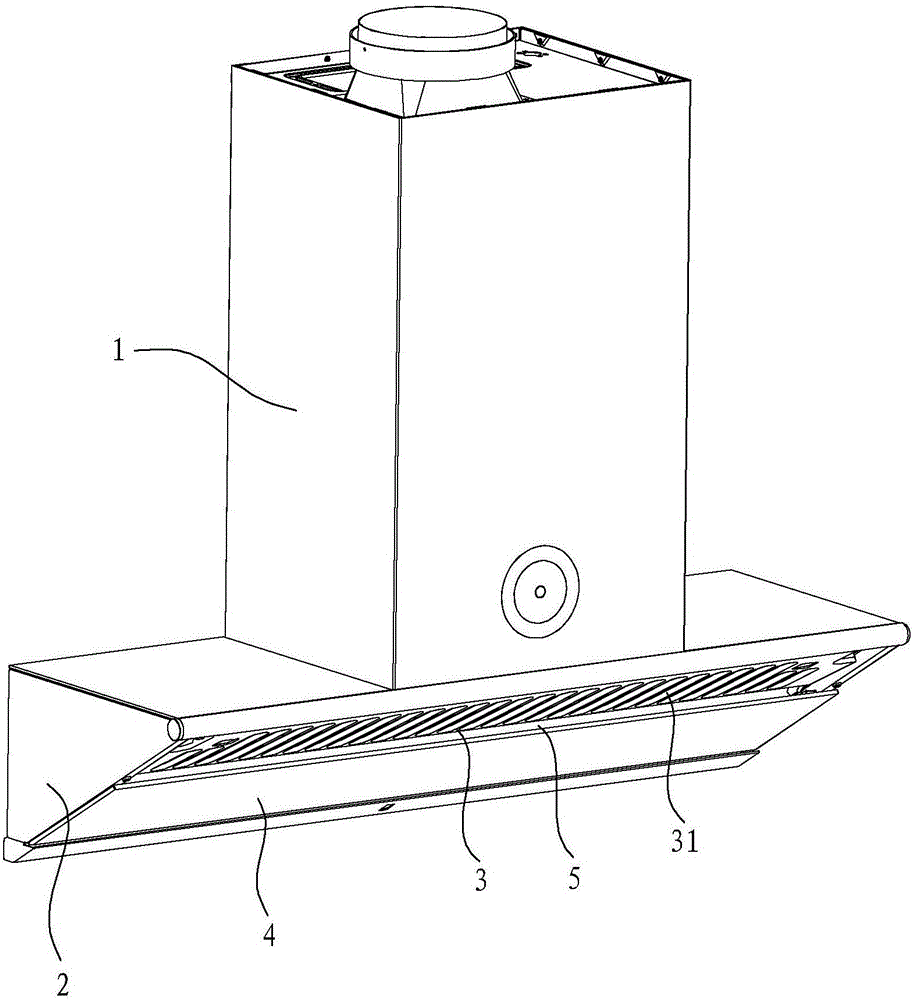

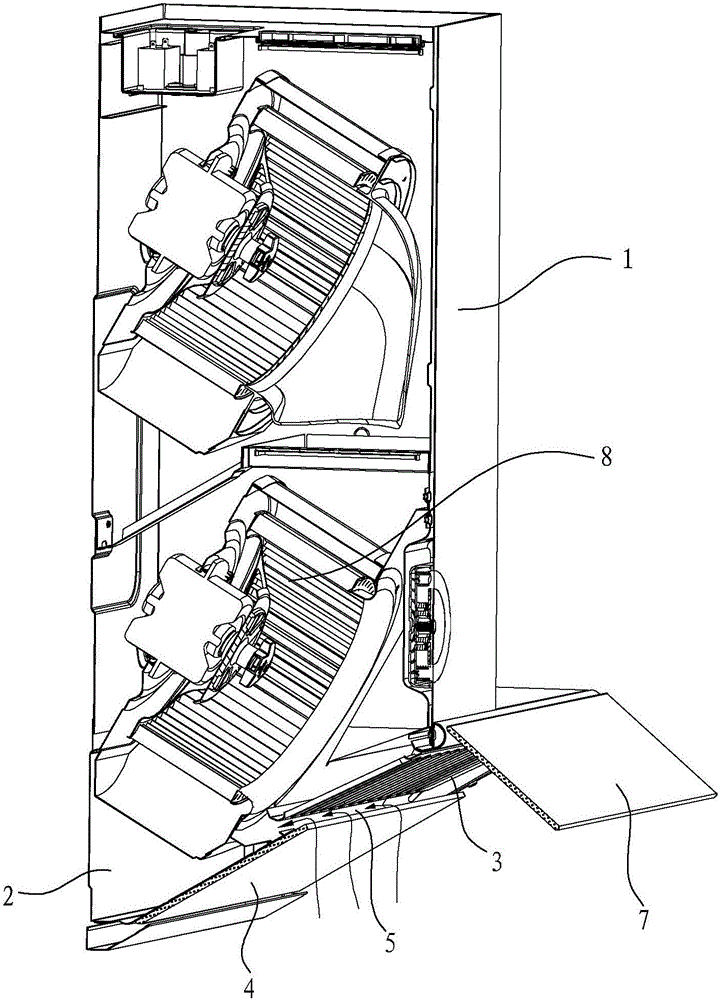

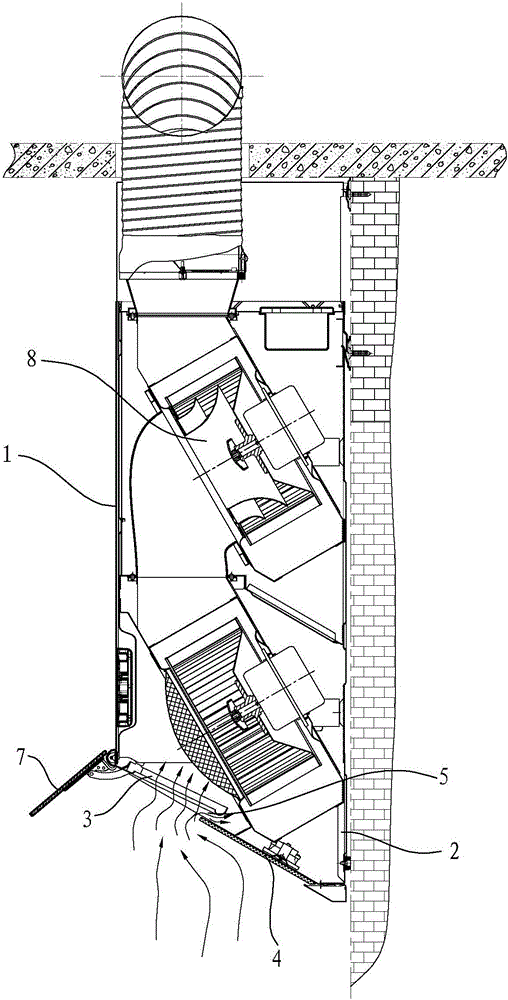

[0028] like Figure 1 to Figure 3 As shown, the range hood in this embodiment includes a range hood casing 1, a fume collecting hood 2 and a fan system 8, the fume collecting hood 2 is installed at the bottom of the range hood casing 1, and the fan system 8 is installed on the range hood casing 1 interior. The side of the smoke collecting hood 2 in this embodiment is triangular, and the front of the smoke collecting hood 2 is equipped with an oil filter plate 3 and a smoke guide plate 4, wherein the smoke guide plate 4 is a fixed smoke guide plate and is located on the oil filter plate 3, and the oil filter plate 3 and the smoke deflector 4 are all inclined from top to bottom to the rear and downward. combine Figure 8 As shown, the oil filter plate 3 is strip-shaped, and the oil filter plate 3 is provided with grid-shaped main air inlets 31, and the main air inlets 31 are distributed at intervals along the length direction of the oil filter plate 3, that is, the main air inl...

Embodiment 2

[0035] like Image 6As shown, the auxiliary air inlet of the range hood in this embodiment is the upper auxiliary air inlet 6, and the gap between the oil filter plate 3 and the upper edge of the front side of the smoke collecting hood 2 constitutes the upper auxiliary air inlet 6, that is, the upper auxiliary air inlet 6. The upper auxiliary air inlet 6 is located in the area adjacent to the upper side of the oil filter plate 3 . Moreover, the rear side of the oil filter plate 3 is overlapped on the front side of the smoke guide plate 4, the inclination angle of the oil filter plate 3 and the smoke guide plate 4 is the same, and the inclination angle is the same as that of the oil filter plate 3 in the first embodiment. The angle of inclination is the same.

[0036] When the range hood works, the movable smoke baffle 7 is opened to expose the upper auxiliary air inlet 6, and when the range hood stops working, the movable smoke baffle 7 is closed to close the upper auxiliary ...

Embodiment 3

[0038] like Figure 7 As shown, the auxiliary air inlet of the range hood in this embodiment includes a lower auxiliary air inlet 5 and an upper auxiliary air inlet 6, wherein the structure of the lower auxiliary air inlet 5 is the same as that of the lower auxiliary air inlet in Embodiment 1, The structure of the upper auxiliary air inlet 6 is the same as that of the upper auxiliary air inlet in the second embodiment, and the inclination angle of the oil filter plate 3 is the same as that of the oil filter plate 3 in the first embodiment.

[0039] When the range hood is working, the movable smoke baffle 7 is opened to expose the upper auxiliary air inlet 6 and the lower auxiliary air inlet 5; when the range hood stops working, the movable smoke baffle 7 is closed so that the upper auxiliary air inlet 6 and the lower auxiliary air inlet The auxiliary air inlets 5 are all closed. Compared with Embodiment 1 and Embodiment 2, after adopting the upper auxiliary air inlet 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com