Method for prevention of nitrogen increase in molten steel during steel tapping from a converter

A technology of tapping process and converter, applied in the direction of manufacturing converters, etc., can solve problems such as no relevant reports, and achieve the effect of reducing nitrogen increase in molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

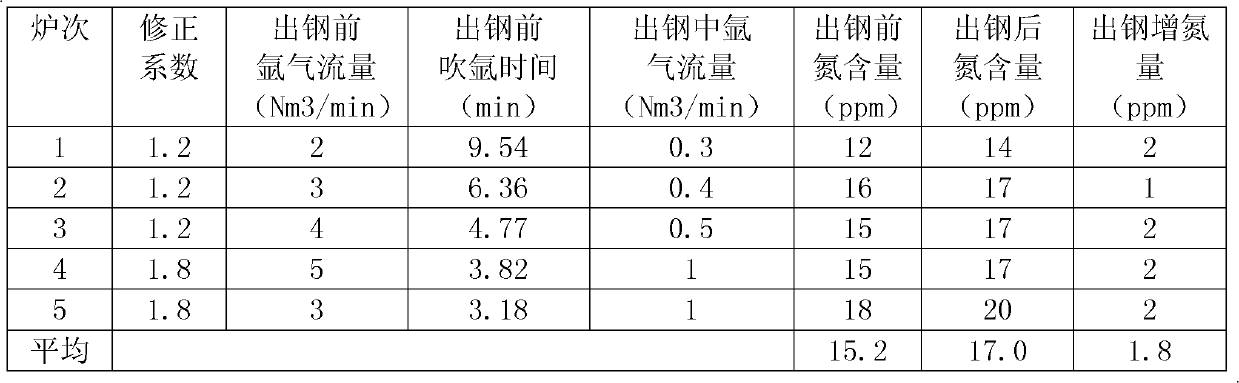

[0023] A 180-ton converter is used to produce IF steel with a nitrogen upper limit of 0.005%, and the diameter of the ladle is 3.852m and the height is 4.915m. Two stages of argon blowing before tapping and after tapping are adopted. The specific process parameters and effects of each furnace are shown in Table 1:

[0024] Table 1 Specific process parameters and effect table of the two-stage argon blowing method before tapping and after tapping

[0025]

Embodiment 2

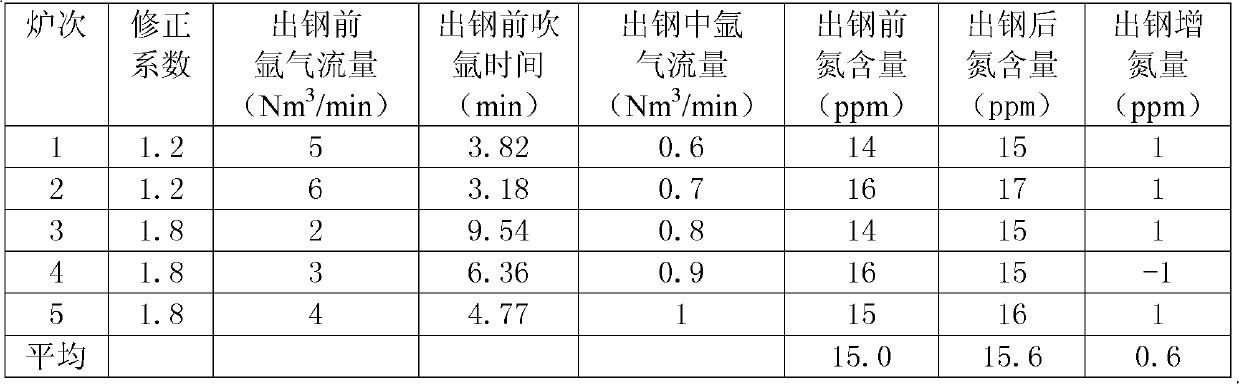

[0027] A 180-ton converter is used to produce IF steel with a nitrogen upper limit of 0.005%, and the diameter of the ladle is 3.852m and the height is 4.915m. Continuous and uninterrupted blowing of argon before and after tapping is adopted until the end of tapping. The specific process parameters and effects of each furnace are shown in Table 2:

[0028] Table 2 Specific process parameters and effect table of uninterrupted argon blowing before and after tapping

[0029]

[0030] The heat nitrogen increasing result that does not adopt the inventive method in the same period is as shown in table 3:

[0031] Table 3 does not adopt the furnace time nitrogen increasing result table of the inventive method

[0032] Stoves

[0033] As can be seen from the comparison of tapping nitrogen increasing amount in the above list table, the nitrogen increasing amount of molten steel after adopting the inventive method to tap has only 1.2ppm on average, but the heat nitrogen i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com