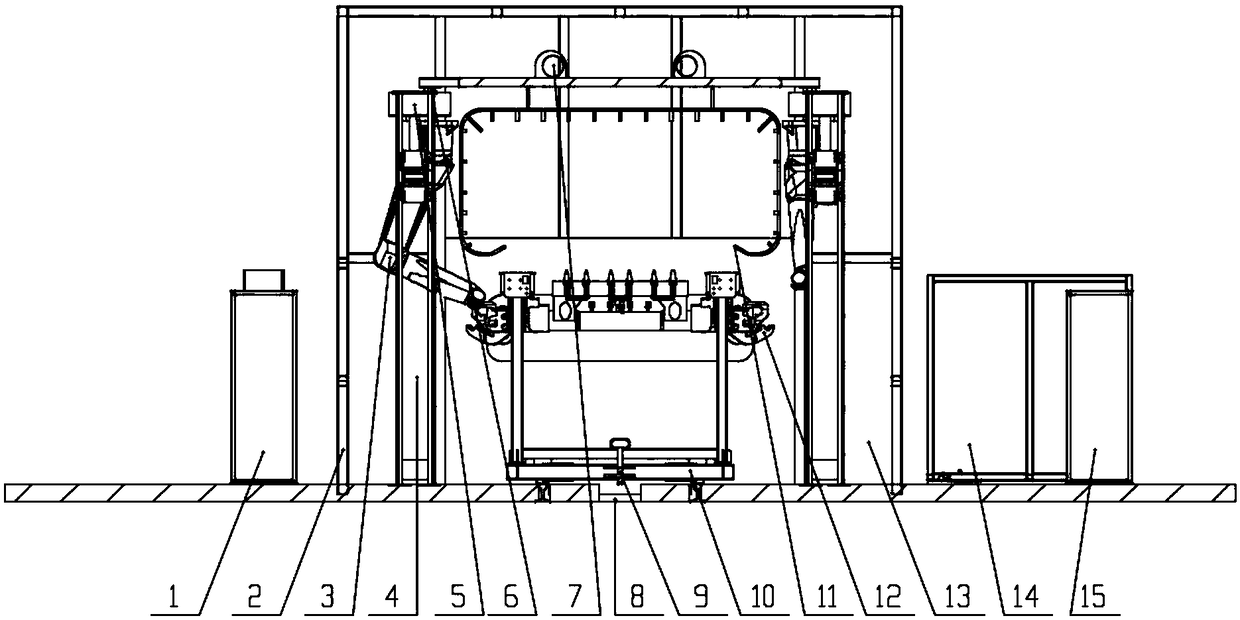

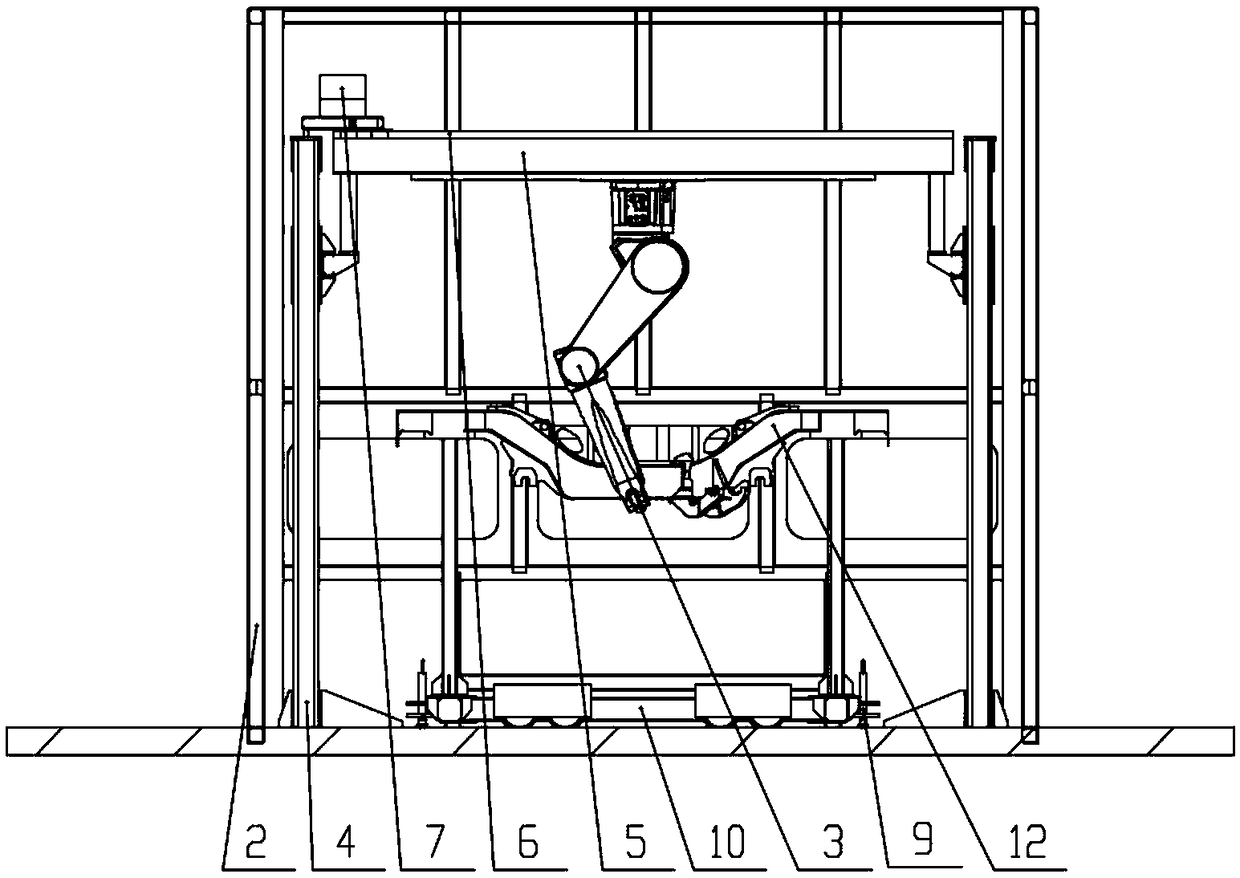

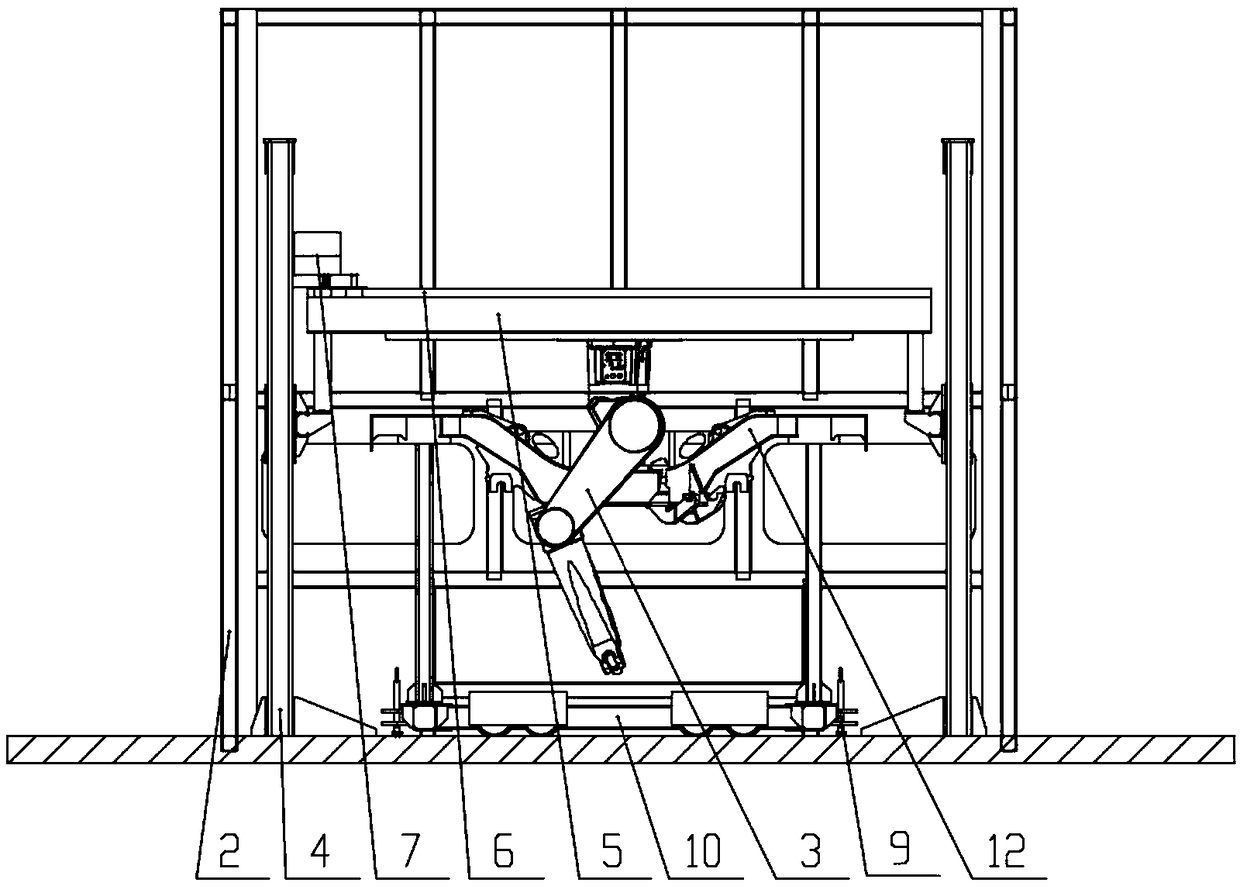

Cleaning and depainting system and inspection device for rail vehicle bogies

A rail car and paint stripping technology, applied in the field of rail transit, to improve the efficiency of cleaning and paint stripping, compact space layout and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Any technical features and any technical solutions in the embodiments are one or more of a variety of optional technical features or optional technical solutions. For the sake of concise description, all possible options of the present invention cannot be exhaustively listed in this document. Alternative technical features and alternative technical solutions are not convenient for the implementation of each technical feature to emphasize that it is one of multiple optional implementations, so those skilled in the art should know that any of the present invention can be used Replace one technical means or combine any two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com