Automatic sesame shelling and sieving machine

A sieving machine and sesame technology, which is applied in the direction of fat production, fat oil/fat production, etc., can solve the problems of smashing sesame stalks, affecting sesame sieving, and low work efficiency, so as to achieve high-efficiency shelling, increase the frequency of beating, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

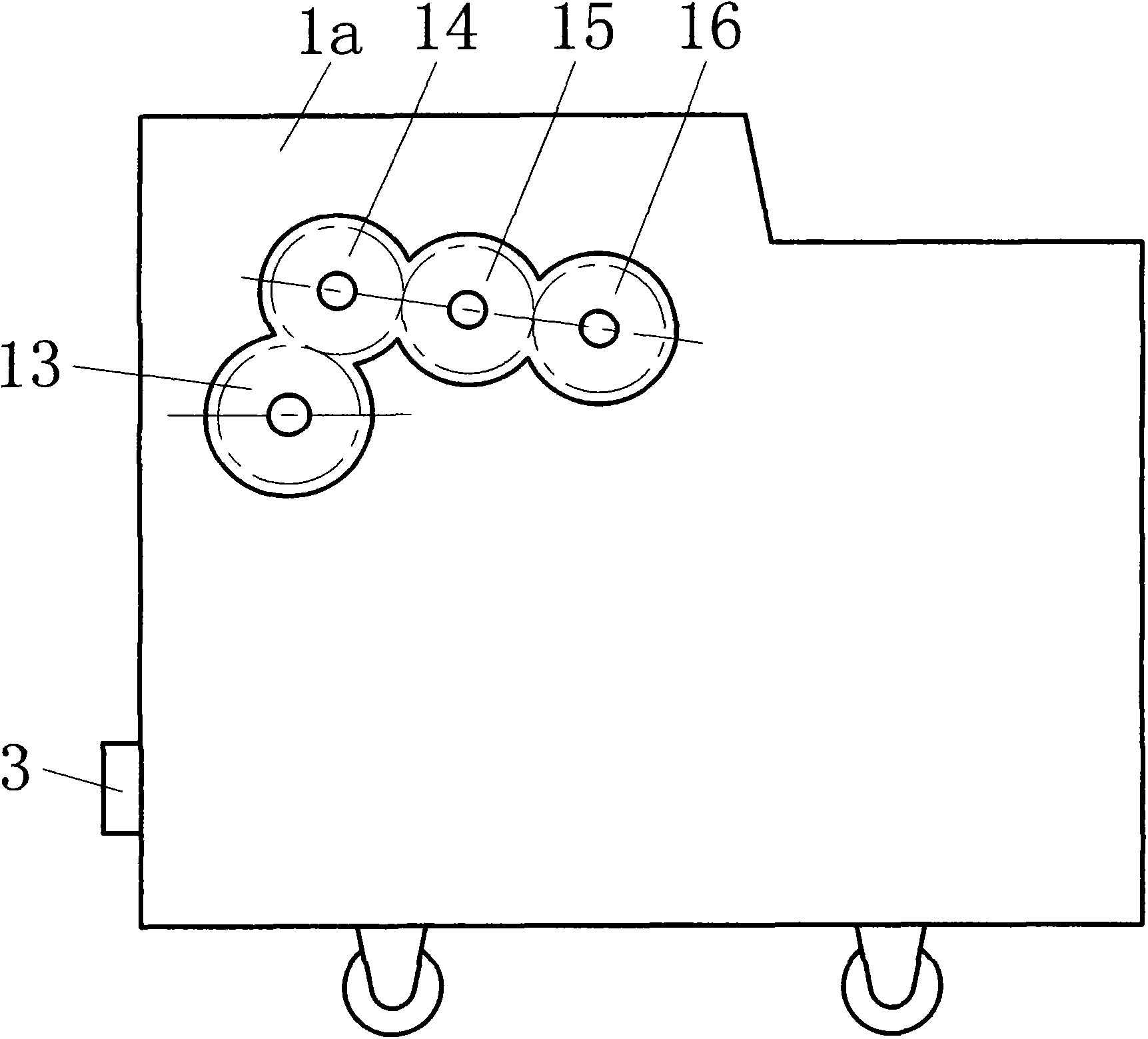

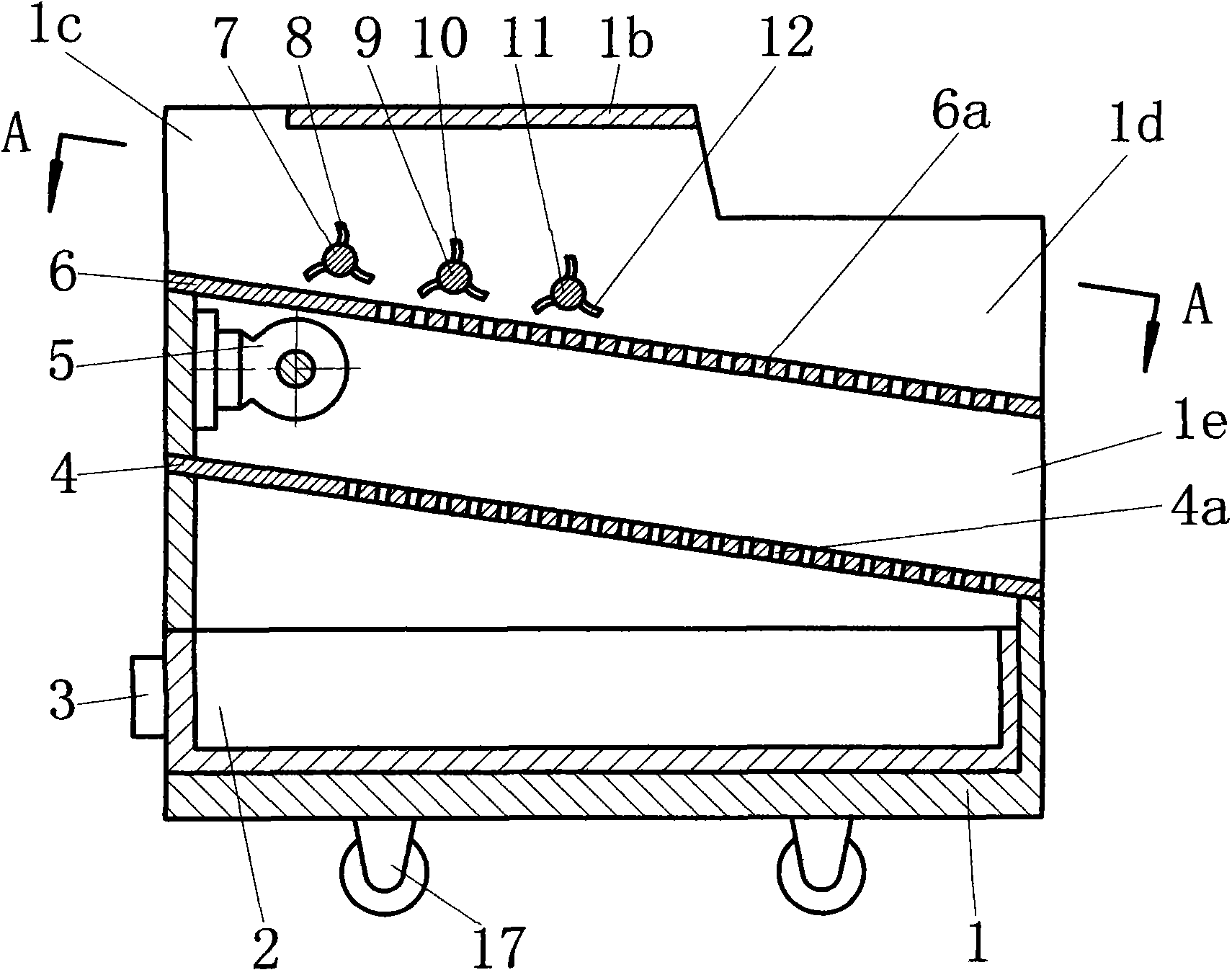

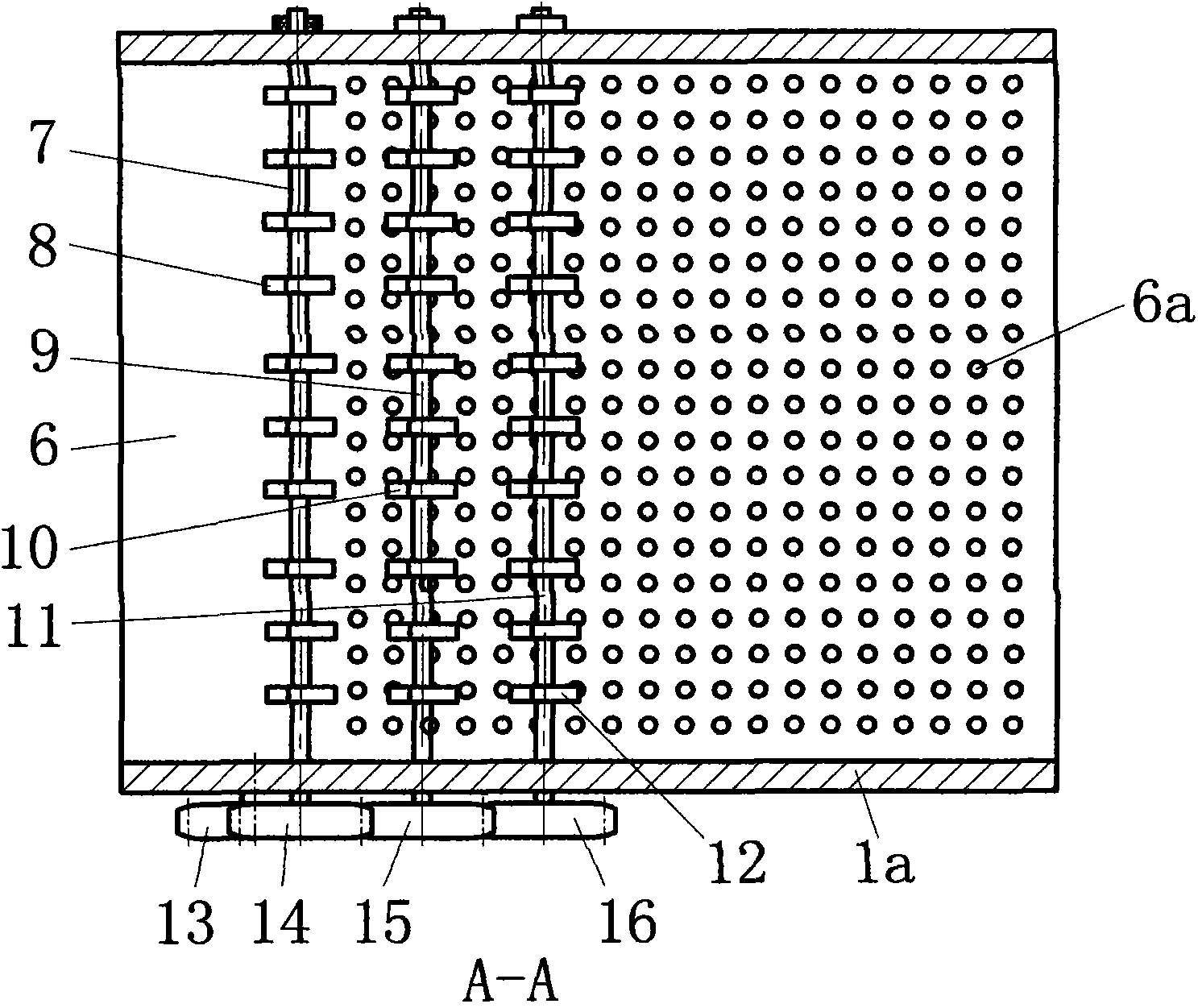

[0028] Such as figure 1 , figure 2 , image 3 Shown, a kind of automatic sesame husking and screening machine comprises frame 1, and the front and back sides of described frame 1 are symmetrically provided with mounting plate 1a, and the lower end of described frame 1 is provided with walking wheel 17, and in use like this In the process, the operator can push the present invention to a designated place for processing according to actual needs. The top of the frame 1 is provided with a protective plate 1b, and the protective plate 1b can prevent debris from flying in the shelling process. out, which plays a good role in protecting the operators; the lower part of the frame 1 is slidingly connected with a storage cabinet 2, the storage cabinet 2 is located in the frame 1, and the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com