Multi-stage serial bubbling bed-transporting bed superimposed CO2 adsorption reactor and method thereof

A technology of bubbling bed and transport bed, which is applied in the field of multi-stage serial bubbling bed-transport bed stacked CO2 adsorption reactors, can solve the problem of large deviation of adsorbent residence time, inconsistent carbonation degree of adsorbent, Increased system energy consumption and other issues to achieve the effect of improving flexibility and universality, broad industrial application prospects, and compact space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

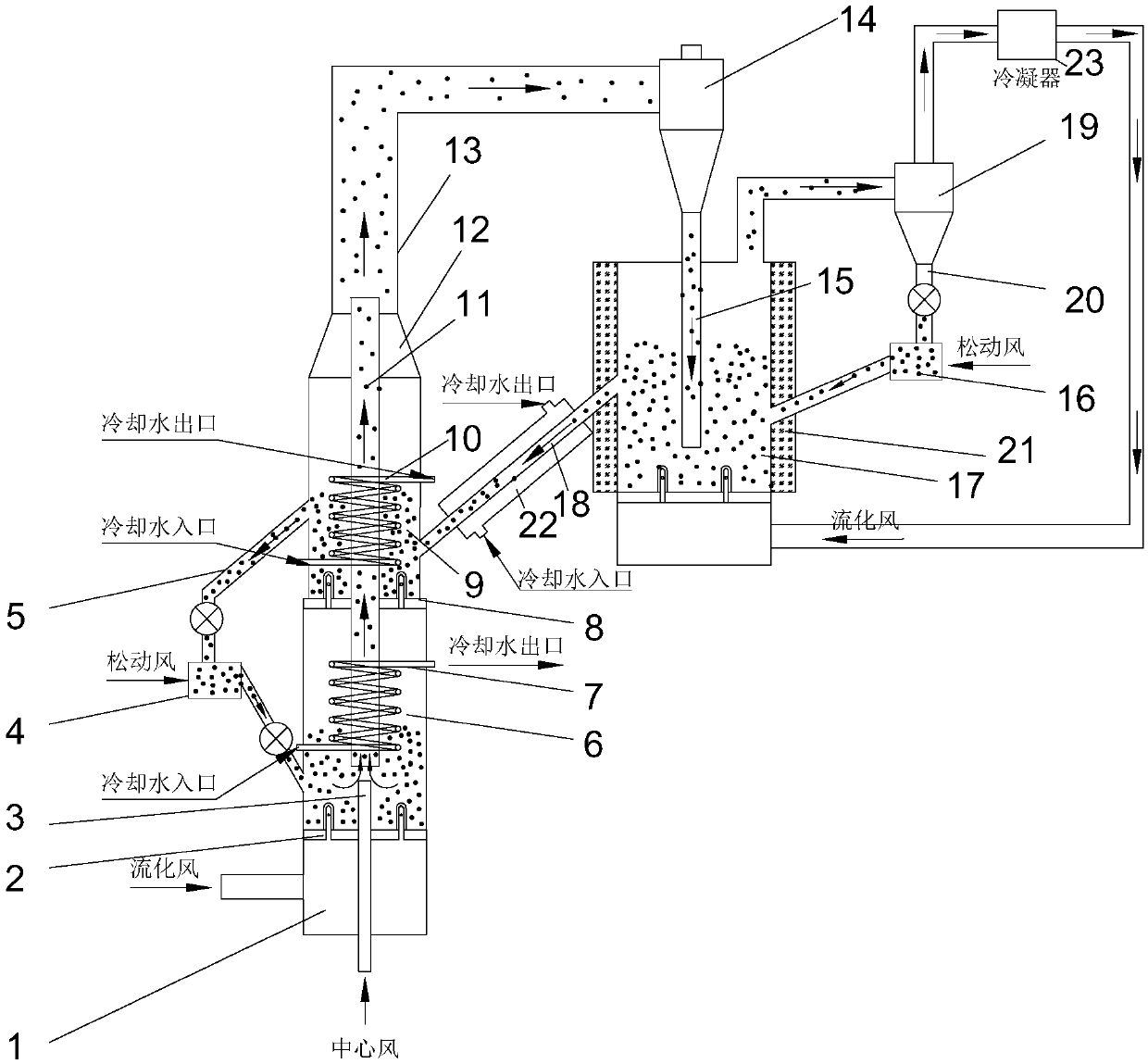

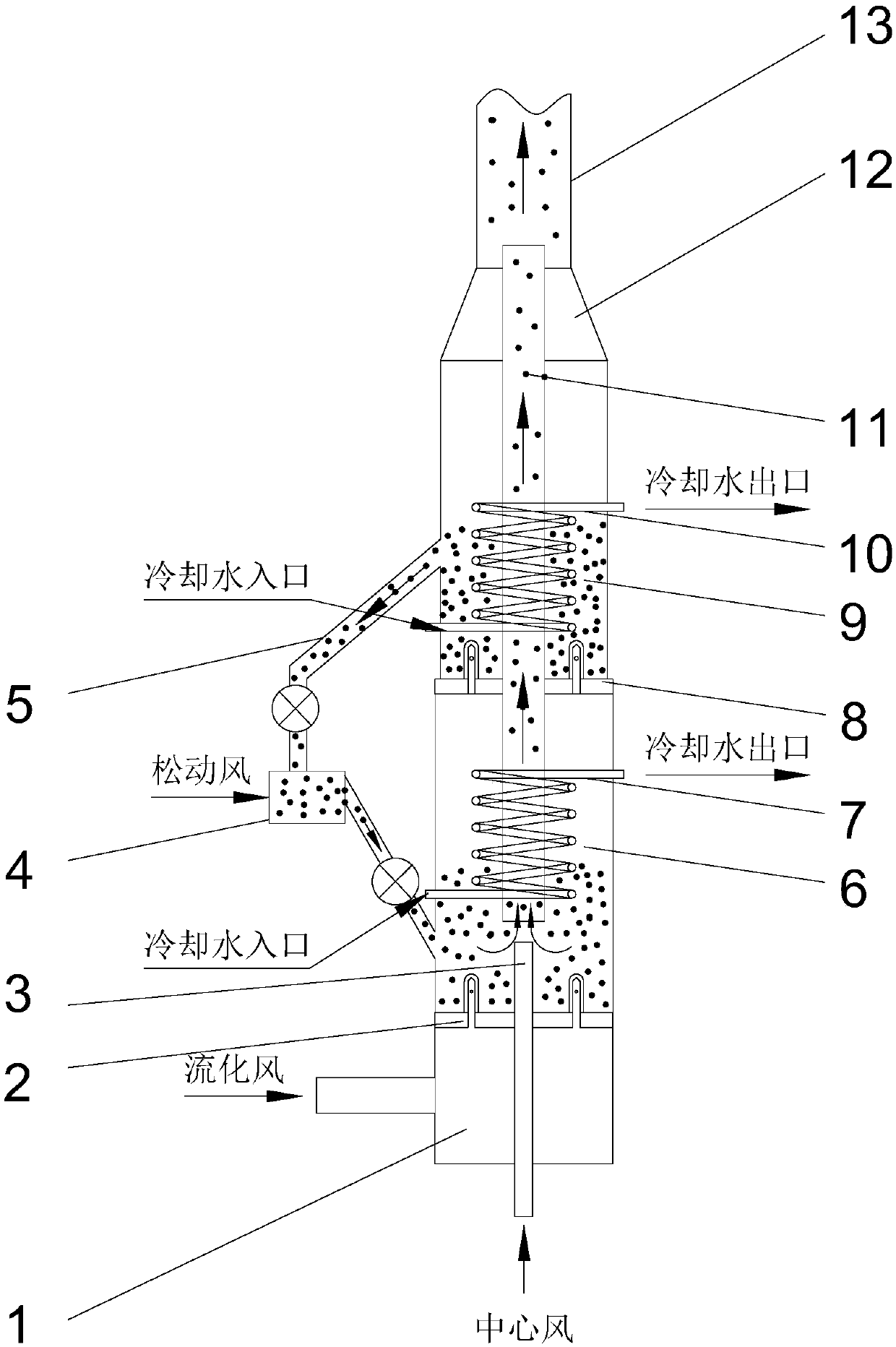

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0031] A multi-stage serial bubbling bed-transportation bed stacked CO of the present invention 2 Adsorption reactors, such as figure 1 , 2 As shown in and 3, this embodiment takes two bubbling beds as an example, and the bottom of the air chamber 1 is set to provide 2 For the flue gas fan, the first-stage bubbling bed 6 and the second-stage bubbling bed 9 are sequentially arranged on the air chamber 1, and the diameter of the second-stage bubbling bed 9 is smaller than that of the first-stage bubbling bed 6; 2 The flue gas enters from the wind chamber 1 at the bottom, and the CO in the first-stage bubbling bed 6 2 After the decarbonization reaction of the adsorbent, the CO in the flue gas 2 and water vapor will be reduced, so that the amount of flue gas flowing through the second-stage bubbling bed 9 is reduced, so that the CO in the second-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com