Art cold transfer printing system and method thereof

A technology of cold transfer printing and art, applied in the field of art, can solve the problems of poor transfer printing effect, achieve the effect of low overall cost, suitable for large-scale production and promotion, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

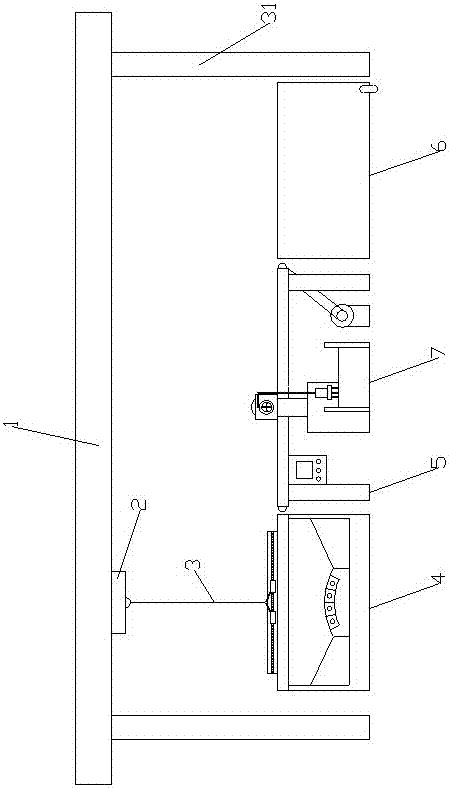

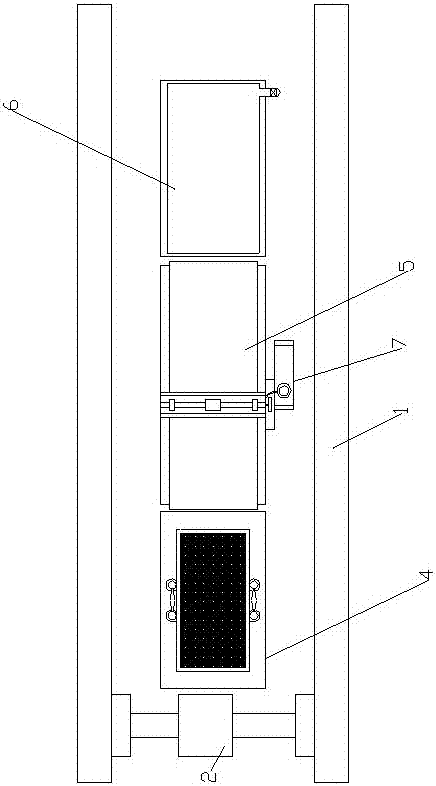

[0030] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a kind of art cold transfer printing system is characterized in that: the system includes an upper supporting device, a film-making device installed on the lower side of the upper supporting device, arranged on the The flow coating device on one side of the film device is arranged on the transfer device on the side of the flow coating device, and the flow coating device is installed in the middle of the film making device and the transfer device.

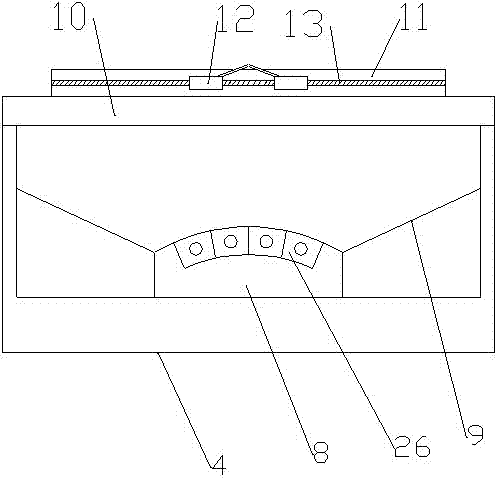

[0031]The upper support device includes a support 31 and a double support beam 1 installed on the upper part of the support 31, a crane 2 is movable on the double support beam 1, a suspension rope 3 is arranged on the lower part of the crane 2, and the film-making device is installed on the support. Inside the seat 31, the film-making device includes a film-making support box 4, a baking lamp 26 is installed in the film-making support box 4, a high-temperature-resistant glass pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com