Flexible workpiece transferring system with temporary storage function

A flexible and workpiece technology, applied in the field of flexible workpiece transfer systems, can solve the problems of difficult production scheduling, large space occupation, and high robot cost for multiple types of workpieces to be processed, achieving extremely economical and practical, compact space. The effect of layout and multi-planning space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

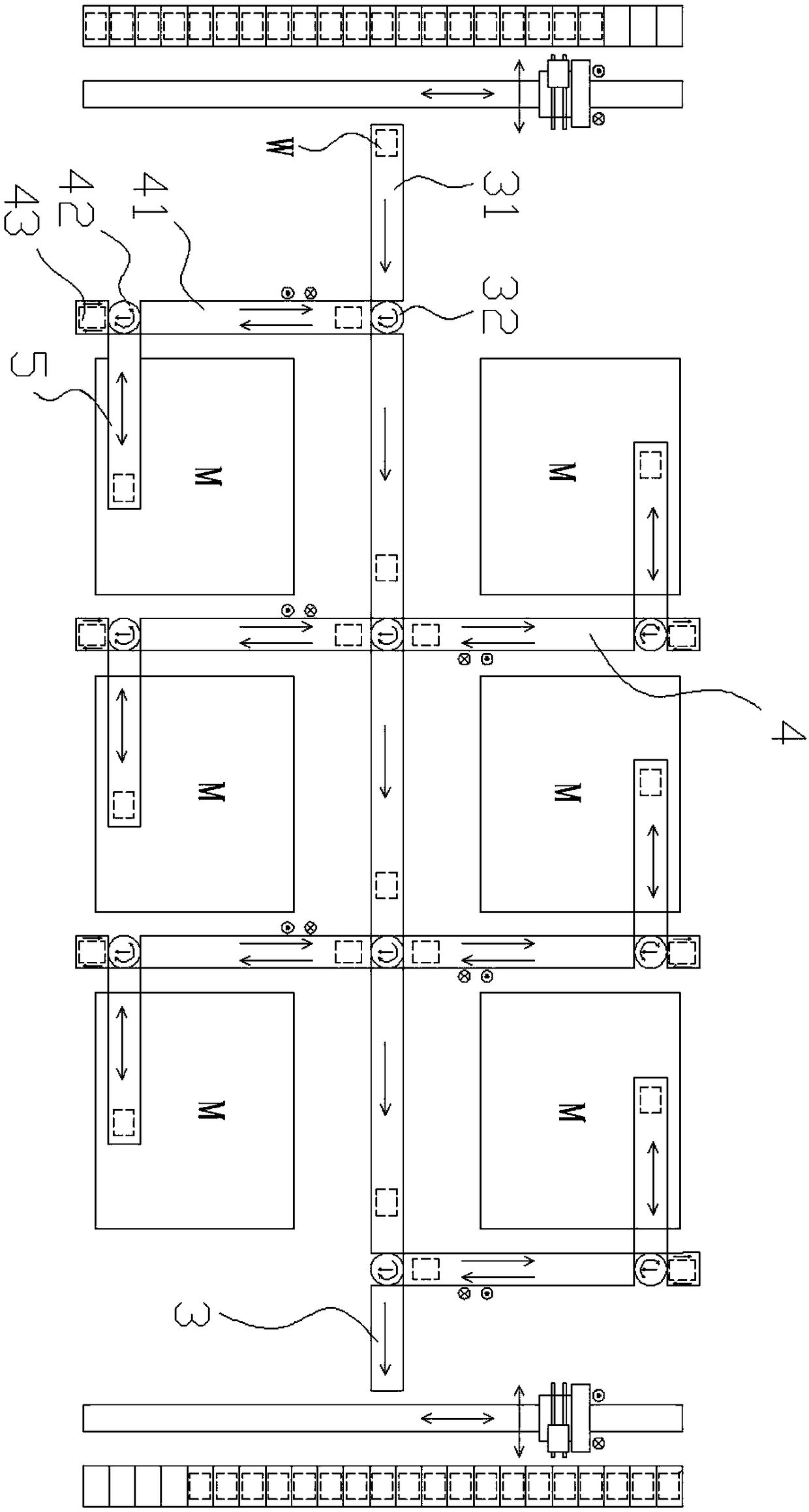

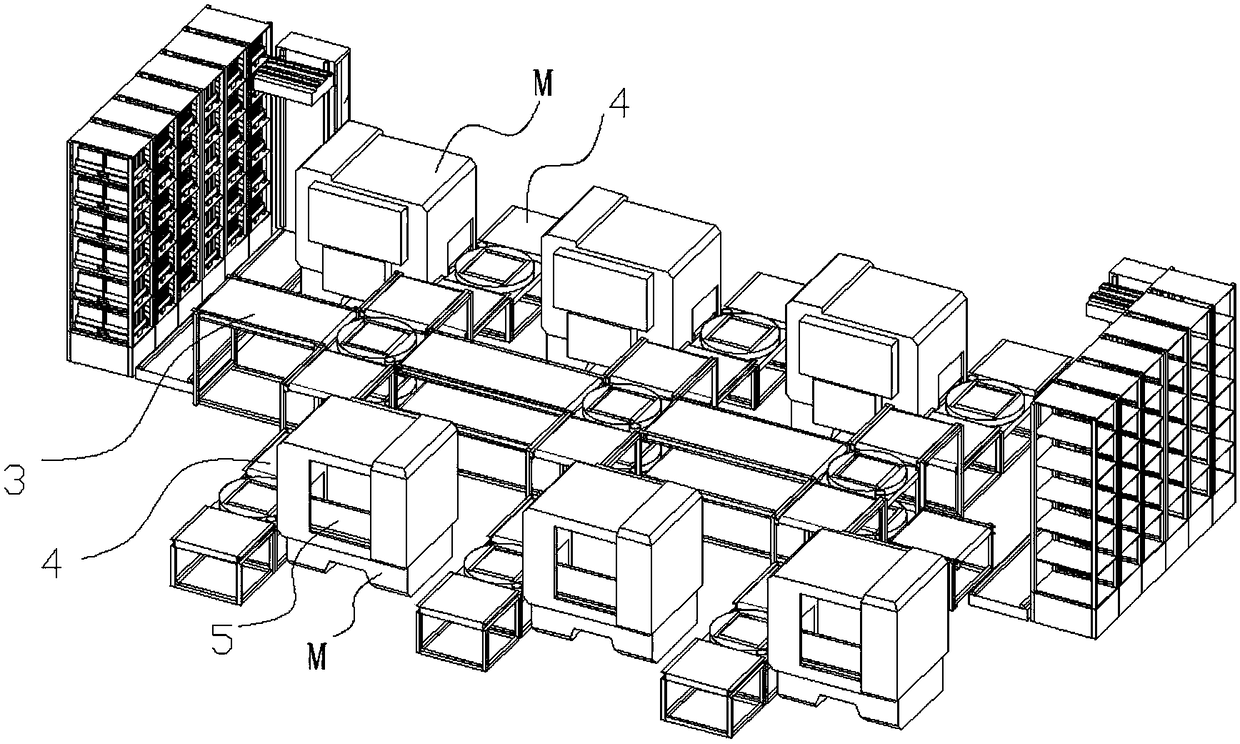

[0092] According to the fourth embodiment of the present invention, the workpiece flexible transfer system with buffer function has substantially the same structure as that of the first embodiment, the difference is that the flexible workpiece transfer system with buffer function in the first embodiment The system is a basic transfer unit. In this embodiment, the workpiece flexible transfer system with buffer function has multiple basic transfer units. Each basic transfer unit may be arranged side by side along a direction perpendicular to the first transfer line 3 .

no. 5 example

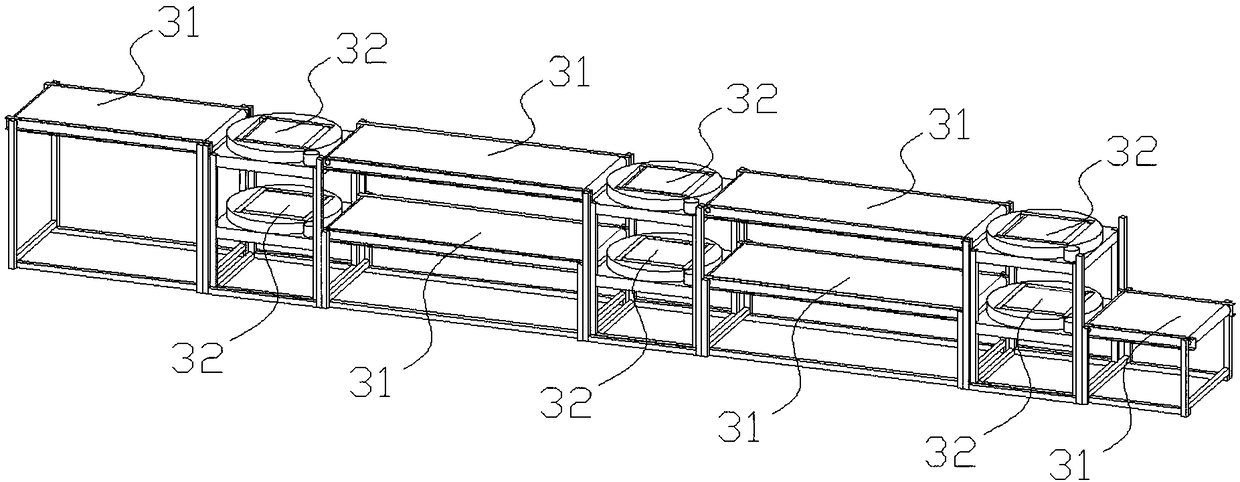

[0093] According to the fifth embodiment of the present invention, the workpiece flexible transfer system with buffer function has substantially the same structure as the first embodiment, the difference is that the first transfer line 3 has a multi-layer structure, that is, not only has the upper There are two layers of transfer line and lower transfer line, and the lifting transfer line of the second transfer line 4 can also be connected with each layer, so as to realize the transfer of more workpieces W between different layers.

[0094] The flexible workpiece transfer system with cache function provided by the present invention has been described in detail above, and the following points need to be explained:

[0095] 1. The present invention does not limit the way the workpiece is placed on the transfer line. The workpiece can be placed on the transfer line manually, or it can be placed on the transfer line by an automated method, such as a robot.

[0096] 2. The workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com